Method for preparing natural gas by dry quenching co-production coal

A coal-to-natural gas and coke CDQ technology, which is applied in coke cooling, combustible gas production, coke oven, etc., can solve the problems of reducing the unit calorific value of pyrolysis gas, fuel consumption, air pollution, etc., and achieve simplified operation process and equipment maintenance, investment reduction, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

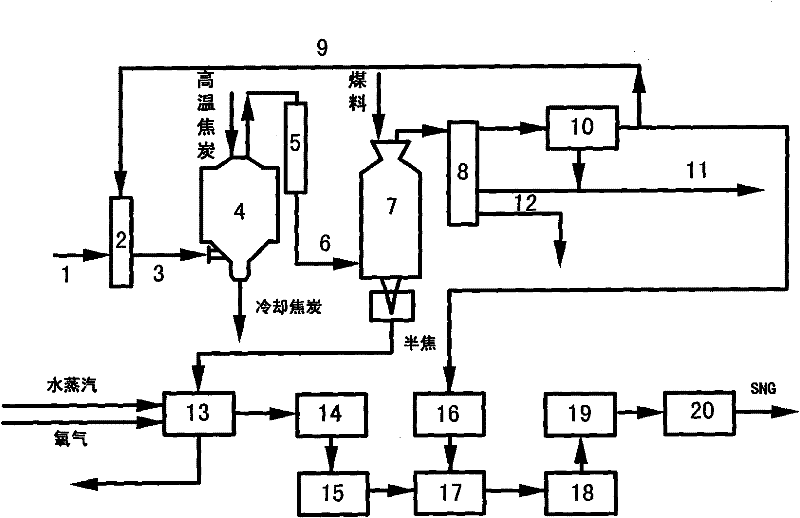

[0031] Such as figure 1 , to implement the method of CDQ co-production of coal-to-natural gas, firstly, the reducing gas is passed into the gas mixer 2 through the reducing gas pipeline 1, and the circulating heat-carrying gas is passed into the gas mixer 2 through the circulating heat-carrying gas pipeline 9 . The reducing gas and the circulating heat-carrying gas are mixed in the gas mixer 2 to form a cold heat-carrying gas, and the cold heat-carrying gas is passed through the heat-carrying gas pipeline 3 from the bottom of the coke quenching tower 4 . The main component of the reducing gas is H 2 , CO and CH 4 , the sum of the volume fractions of the three should be greater than 70%; the circulating heat-carrying gas is a part of the clean gas after the crude gas output from the top of the coal pyrolyzer 7 has been cooled and purified. The high-temperature coke at 900°C-1050°C is loaded into the quenching tower 4 from the top of the quenching tower 4, and the cold heat-c...

Embodiment 2

[0033] Such as figure 1 , to implement the method of CDQ co-production of coal-to-natural gas, firstly, the reducing gas is passed into the gas mixer 2 through the reducing gas pipeline 1, and the circulating heat-carrying gas is passed into the gas mixer 2 through the circulating heat-carrying gas pipeline 9 . The reducing gas and the circulating heat-carrying gas are mixed in the gas mixer 2 to form a cold heat-carrying gas, and the cold heat-carrying gas is passed through the heat-carrying gas pipeline 3 from the bottom of the coke quenching tower 4 . The main component of the reducing gas is H 2 , CO and CH 4 , the ratio of the three can be zero in theory, but in practice, its H 2 , CO and CH 4 One of the three cannot be zero, because in general, coke oven gas is used, not pure gas, no matter the proportion of the three, as long as the sum of the three volume fractions should be greater than 70%; The hot gas is a part of the clean gas after the crude gas output from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com