Supercritical safflower extracting process

A supercritical and safflower technology, applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., to achieve the effects of easy production of high-concentration pharmaceutical preparations, high yield, and high product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

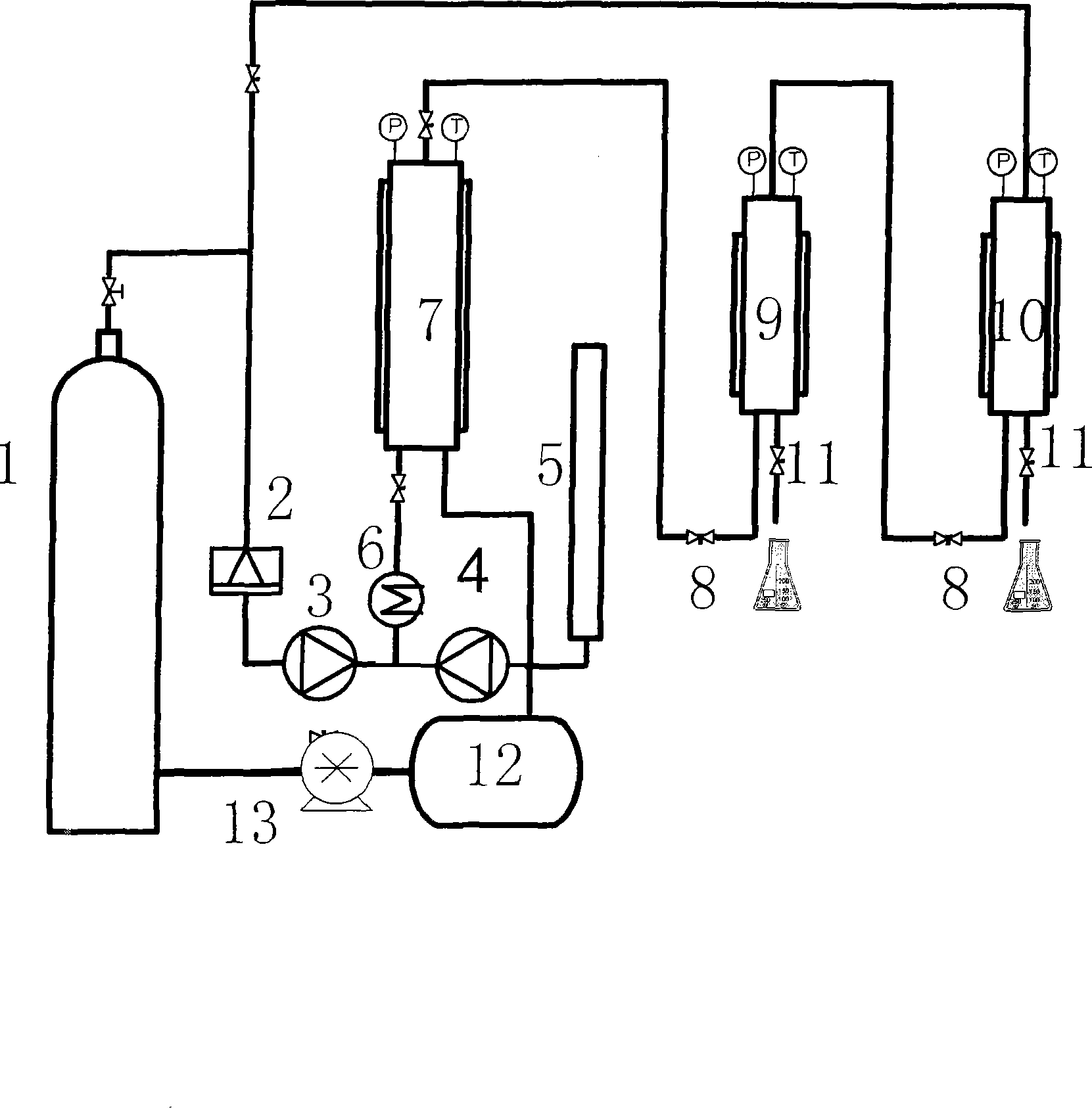

[0020] Example 1: Take 100 grams of safflower, crush it to 0.15mm-1mm, dry it at a low temperature below 60°C, put it in the extraction tank 7 and seal it. Open the gas tank 1, the carbon dioxide reaches the extraction tank 7 through the condensation tank 2 and the high-pressure pump 3, and conducts the first extraction at 8MPa and 35°C. The extract enters the primary separation tank 9, and performs primary separation at 8MPa and 12°C to obtain safflower wax. Carbon dioxide continues to enter the secondary separation tank 10, 4MPa, 30 ℃ secondary separation of safflower volatile oil. After 6 hours of dynamic operation, 0.6 grams of safflower volatile oil and 0.1 g of vegetable wax were obtained from the separation tank. The pressure was increased to 32mpa, and the safflower raffinate was extracted for the second time at a temperature of 35°C. The extract enters the separation tank 9 for separation, the pressure of the separation tank is 2MPa, and the temperature is 20°C. Af...

Embodiment 2

[0021] Example 2: Take 100 grams of safflower, crush it to 0.15mm-1mm, dry it at a low temperature below 60°C, put it in the extraction tank 7 and seal it. Open the gas tank 1, the carbon dioxide reaches the extraction tank 7 through the condensation tank 2 and the high-pressure pump 3, and conducts the first extraction at 10MPa and 50°C. The extract enters the primary separation tank 9, and performs primary separation at 9MPa and 10°C to obtain safflower wax. Carbon dioxide continues to enter the secondary separation tank 10, 6MPa, 35 ℃ secondary separation of safflower volatile oil. After 6 hours of dynamic operation, 0.7 g of safflower volatile oil and 0.12 g of vegetable wax were obtained from the separation tank. The pressure was increased to 28mpa, and the safflower raffinate was extracted for the second time at a temperature of 45°C. The extract enters the separation tank for separation, the pressure of the separation tank is 4MPa, and the temperature is 30°C. After ...

Embodiment 3

[0022] Example 3: Take 100 grams of safflower, crush it to 0.15mm-1mm, dry it at a low temperature below 60°C, put it in the extraction tank 7 and seal it. Open the gas tank 1, the carbon dioxide reaches the extraction tank 7 through the condensation tank 2 and the high-pressure pump 3, and conducts the first extraction at 12MPa and 60°C. The extract enters the primary separation tank 9, and performs primary separation at 9MPa and 12°C to obtain safflower wax. Carbon dioxide continues to enter the secondary separation tank 10, 4MPa, 30 ℃ secondary separation of safflower volatile oil. After 2 hours of dynamic operation, 0.9 g of safflower volatile oil and 0.13 g of vegetable wax were obtained from the separation tank. The pressure was increased to 25mpa, and the safflower raffinate was extracted for the second time at a temperature of 60°C. The extract enters the separation tank for separation, the pressure of the separation tank is 6MPa, and the temperature is 40°C. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com