Method for extracting and enriching saussurea involucrate total flavone

A technology of total flavonoids and snow lotus, applied in medical formulas, medical preparations containing active ingredients, plant raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

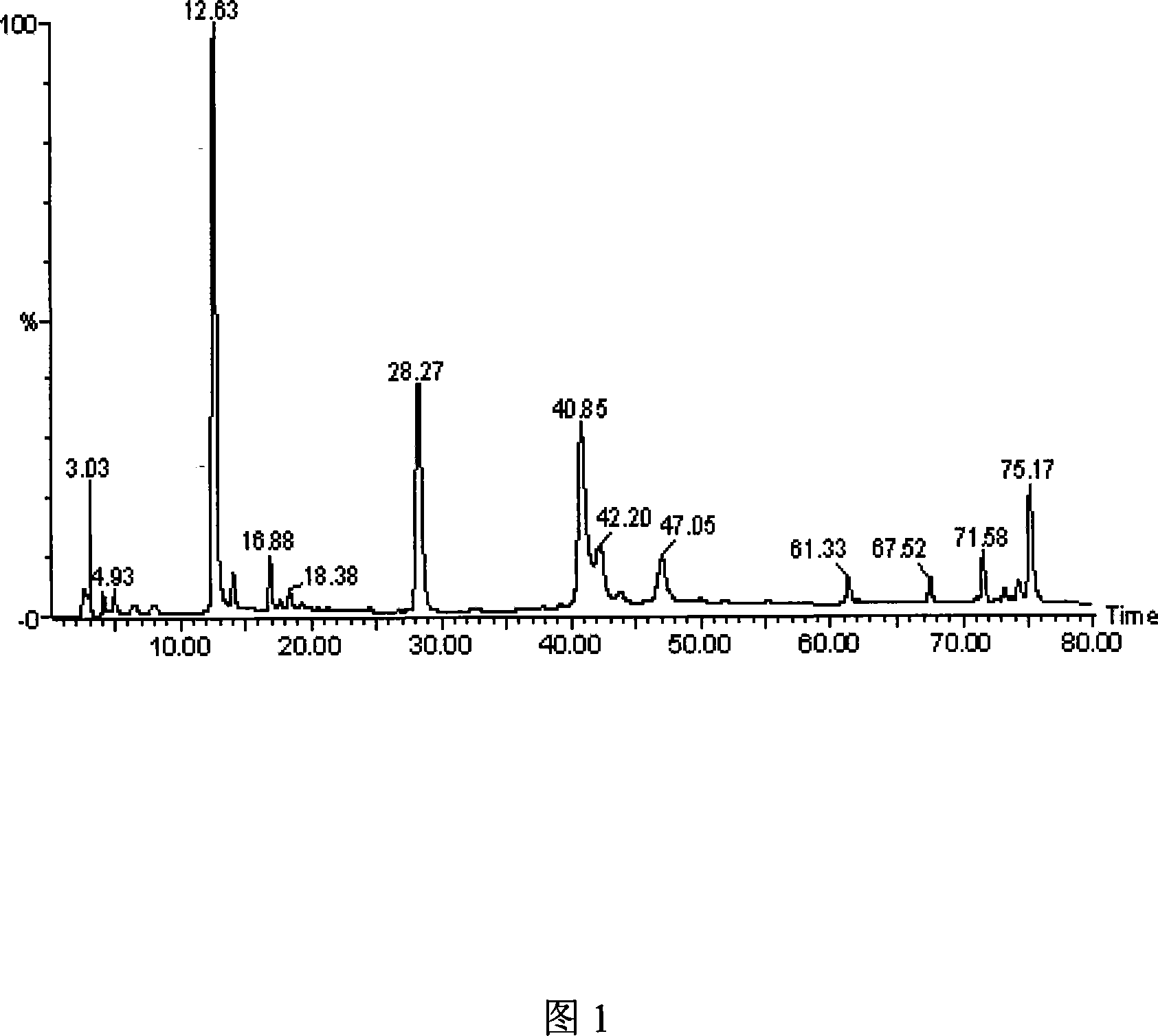

[0050] Get dried 100g of snow lotus whole herb and pulverize it to 40 mesh and put it into a supercritical extraction kettle, start the supercritical carbon dioxide pump, and use supercritical CO 2 For pretreatment, set the extraction temperature to 30°C and use a small amount of CO 2 Exhaust the residual air in the system, then pressurize the extraction tank to 12MP, the temperature of the separation tank is 30°C, adjust the pressure of the separation tank to 4MP, and extract dynamically for 30 minutes;

[0051] After decompression and unloading, the residue in the extraction kettle was extracted with a conventional solvent method, and the residue was extracted with 7 times the amount of 50% ethanol solution at 30°C once for 1 hour each time. After filtering, the filtrate was combined, and the filtrate was concentrated to obtain The extract contains 3.15g of flavonoids;

[0052] Pretreatment of macroporous adsorption resin: Before using HPD type macroporous adsorption resin,...

Embodiment 2

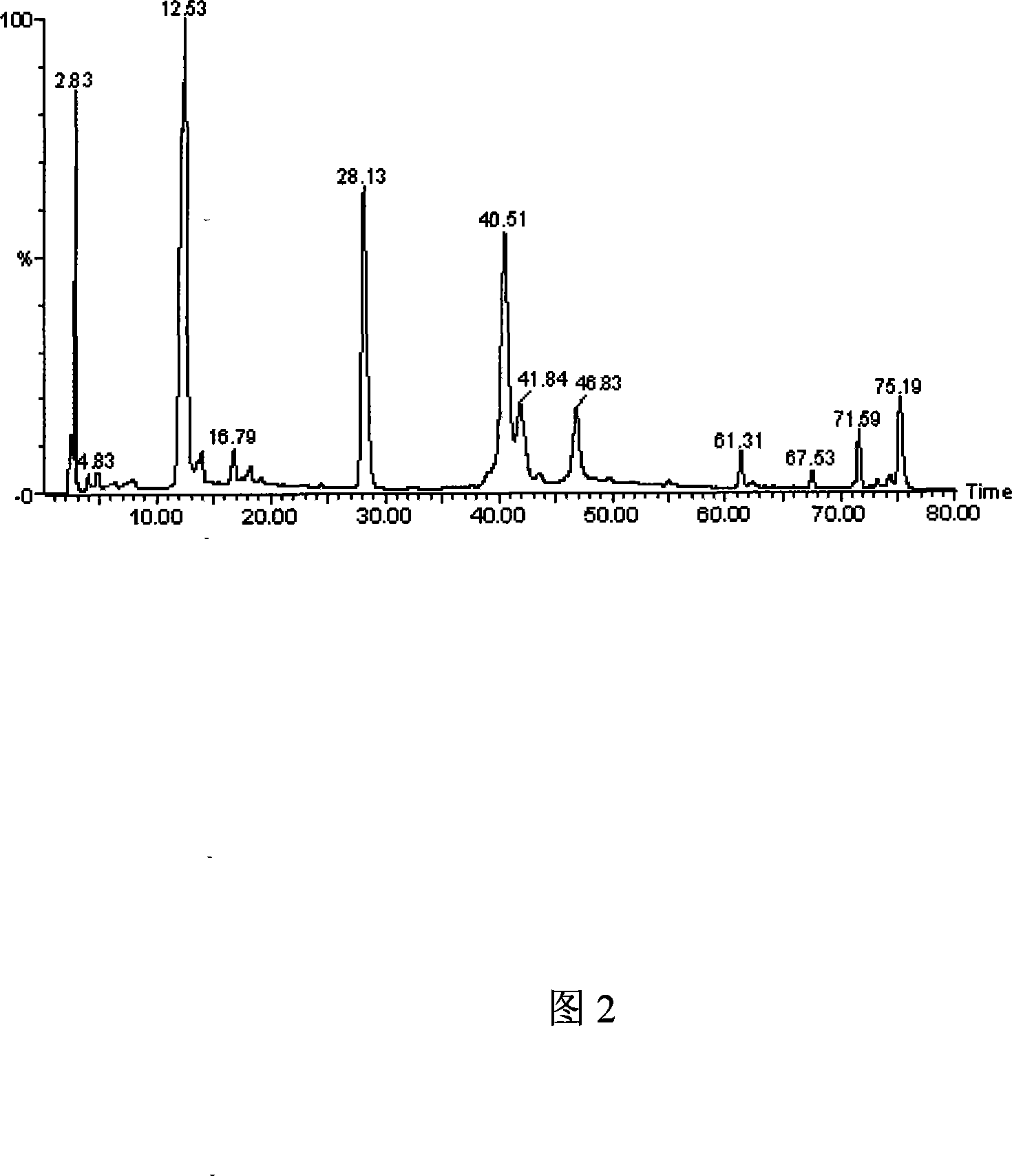

[0055] Get dried 100g of snow lotus whole herb and pulverize it to 80 mesh and put it into a supercritical extraction kettle, start the supercritical carbon dioxide pump, and use supercritical CO 2 Substitute ethanol for pretreatment, set the extraction temperature to 40°C, and use a small amount of CO 2 Exhaust the residual air in the system, then pressurize the extraction tank to 20MP, the temperature of the separation tank is 40°C, adjust the pressure of the separation tank to 6MP, and extract dynamically for 60 minutes.

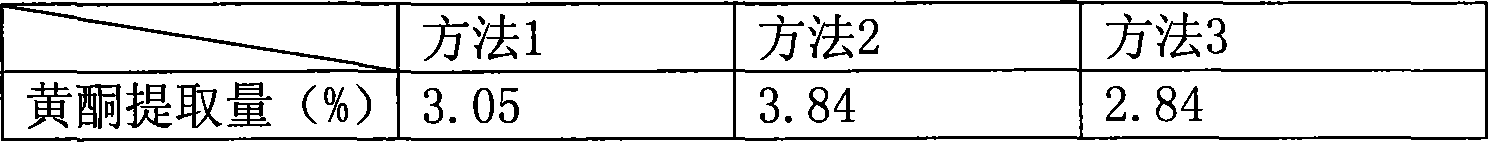

[0056] After decompression and unloading, 2.35 g of supercritical carbon dioxide snow lotus extract was obtained in the extraction kettle, and the residue after supercritical extraction was extracted twice at 60°C with 70% ethanol solution of 10 times the amount, each time for 2 hours, and combined after filtration Filtrate, after the filtrate was concentrated, 2.35 g of flavonoids in the extract was obtained; and 100 g of snow lotus of the same batch was...

Embodiment 3

[0060] Get dried 100g of snow lotus whole herb and pulverize it to 100 mesh and put it into a supercritical extraction kettle, start the supercritical carbon dioxide pump, and use supercritical CO 2 For pretreatment, set the extraction temperature to 45°C and use a small amount of CO 2 Exhaust the residual air in the system, then pressurize the extraction tank to 25MP, the temperature of the separation tank is 30°C, adjust the pressure of the separation tank to 4MP, and extract dynamically for 150 minutes;

[0061] After decompression and unloading, 2.41g of supercritical carbon dioxide snow lotus extract was obtained from the separation kettle, and the residue after supercritical extraction was extracted twice at 55°C with 7 times the amount of 70% ethanol, each for 3 hours, and the filtrate was combined after filtration After the filtrate was concentrated, 2.49g of flavonoids were obtained in the extract; while the crushed 100g snow lotus of the same batch was directly extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com