Process for preliminarily separating antimony from gold in antimony-gold material

A technology for preliminary separation and material, applied in the field of gold metallurgy, can solve the problems of unreported antimony-gold symbiotic ore process and other problems, and achieve the effects of high recovery rate, large processing capacity and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

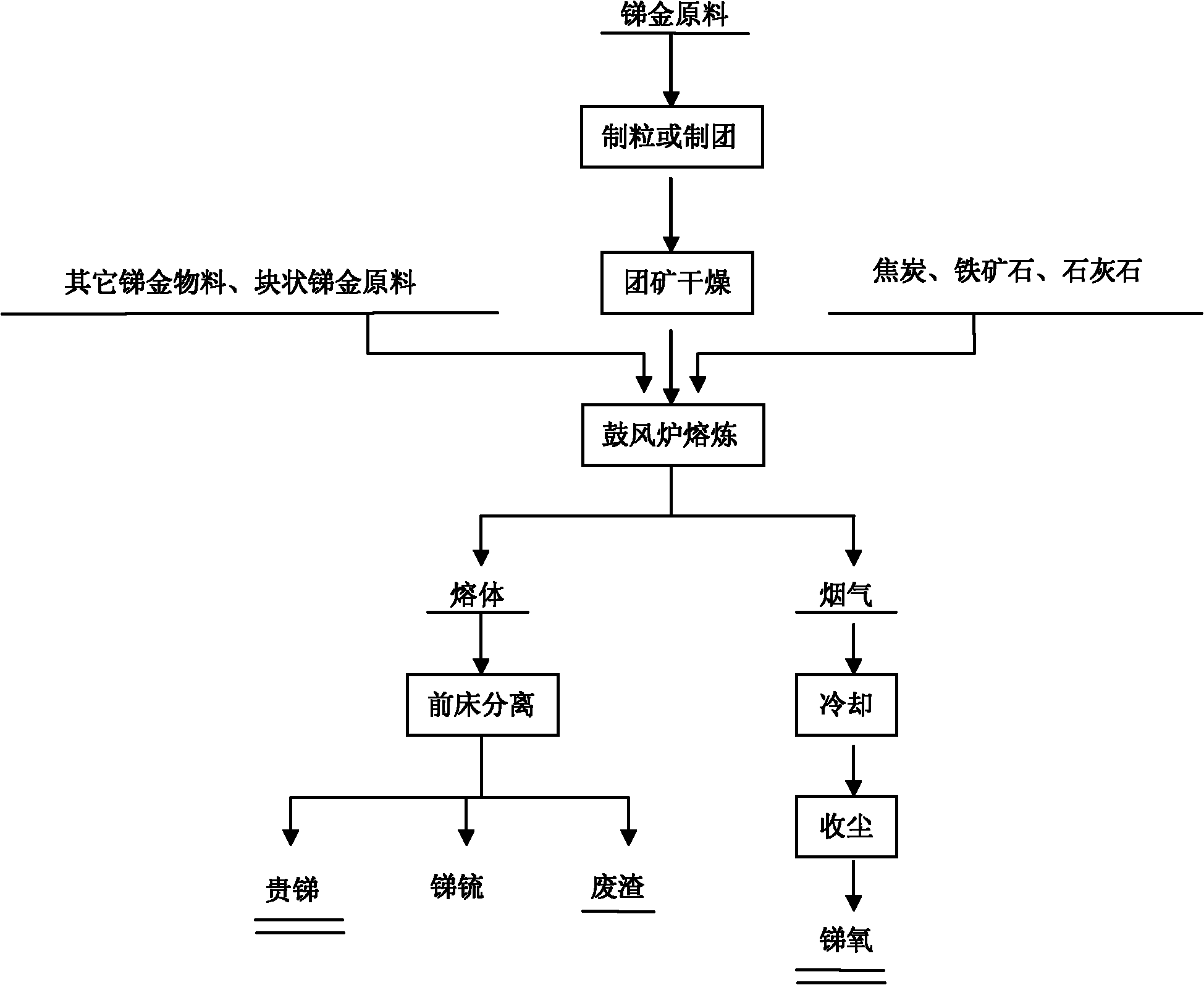

Method used

Image

Examples

Embodiment 1

[0024] The antimony-gold raw material below 5mm is pressed into pellets and dried, then mixed with 16% iron ore and 7.3% limestone, the coke ratio is 28%. 43Hz, feed interval time is 13min, material column height is 750-800mm before feeding. The reaction temperature is 1200°C, the reaction time is 4 hours, and the temperature of the front bed reverberatory furnace is 1200°C. The produced antimony oxide contains 77.4% antimony, and the precious antimony contains 816.13g / t gold.

Embodiment 2

[0026] After the antimony gold raw material below 5mm is pressed into pellets and dried, it is mixed with 16% iron ore, 6.6% limestone, and the coke ratio is 25.3%. 42Hz, feed interval time is 14min, material column height is 800-850mm before feeding. The reaction temperature is 1200°C, the reaction time is 4 hours, and the temperature of the front bed reverberatory furnace is 1200°C. The produced antimony oxide contains 79.8% antimony, and the precious antimony contains 843.87g / t gold.

Embodiment 3

[0028] After pressing antimony gold raw materials below 5mm into pellets and drying them, add 17.3% iron ore, 4% limestone, and the coke ratio is 28%. The gold trapping agent put into the front bed reverberatory furnace is 345kg gross antimony, and the blower frequency is 42Hz, feed interval time is 13min, material column height is 800-850mm before feeding. The reaction temperature is 1200°C, the reaction time is 4 hours, and the temperature of the front bed reverberatory furnace is 1200°C. The produced antimony oxide contains 79.8% antimony, and the precious antimony contains 843.87g / t gold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com