Method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation

A technology coupled with isopropyl acetate and differential pressure heat, applied in separation methods, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of high energy consumption in the rectification process, improve the total conversion rate, and accelerate the reaction rate , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

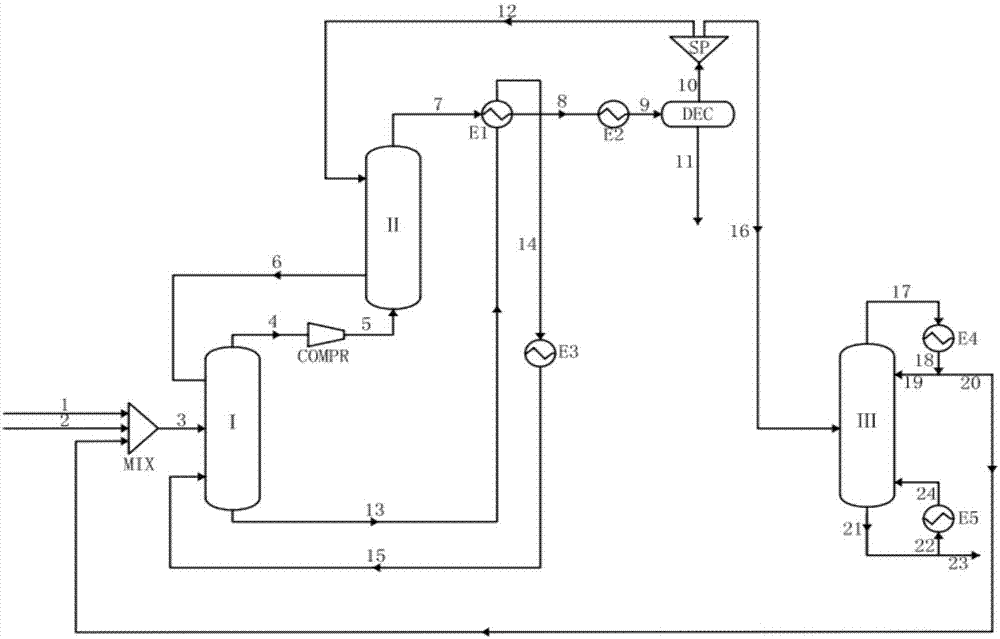

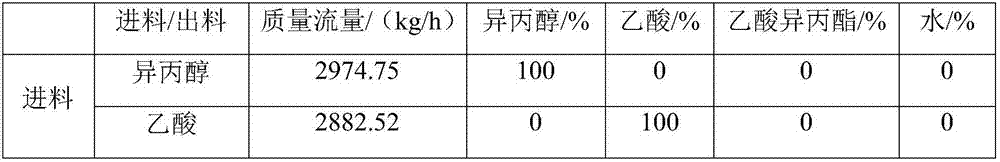

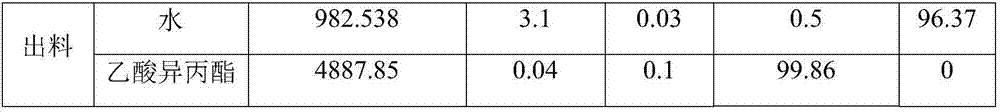

[0030] The differential pressure thermal coupling reaction rectification technological process adopted in embodiment 1 is: raw material isopropanol and acetic acid are mixed with the overhead flow from the product refining tower III in the feed mixer MIX, and then enter the filled acidic cation exchange resin from the bottom of the tower The catalyst is fully reacted and preliminarily separated in the low-pressure reaction section tower I of the catalyst. The gas phase at the top of tower I in the low-pressure reaction section is pressurized and heated by the compressor COMPR, and then enters the bottom tray of tower II in the high-pressure rectification section. The azeotropic mixture of alcohol-water, after extracting the azeotrope, first exchanges heat with the bottom stream of the low-pressure reaction section column I, and then condenses to 50°C through the condenser E2, then enters the phase separator DEC, and separates in the phase separator DEC into an organic phase an...

Embodiment 2

[0039] The differential pressure thermal coupling reaction rectification technological process adopted in embodiment 2 is: raw material isopropanol and acetic acid are mixed with the overhead flow from the product refining tower III in the feed mixer MIX, and then enter the filled acidic cation exchange resin from the bottom of the tower The catalyst is fully reacted and preliminarily separated in the low-pressure reaction section tower I of the catalyst. The gas phase at the top of tower I in the low-pressure reaction section is pressurized and heated by the compressor COMPR, and then enters the bottom tray of tower II in the high-pressure rectification section. The azeotropic mixture of alcohol-water, after extracting the azeotrope, first exchanges heat with the bottom stream of the low-pressure reaction section column I, and then condenses to 50°C through the condenser E2, then enters the phase separator DEC, and separates in the phase separator DEC into an organic phase an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com