Method for extracting high-purity solanesol

A solanesol, high-purity technology, applied in the field of extracting high-purity solanesol, can solve the problems of unrecoverable filler, long production time, and difficulty in realization, and achieves the effects of highly selective separation, reduced difficulty, and enhanced effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

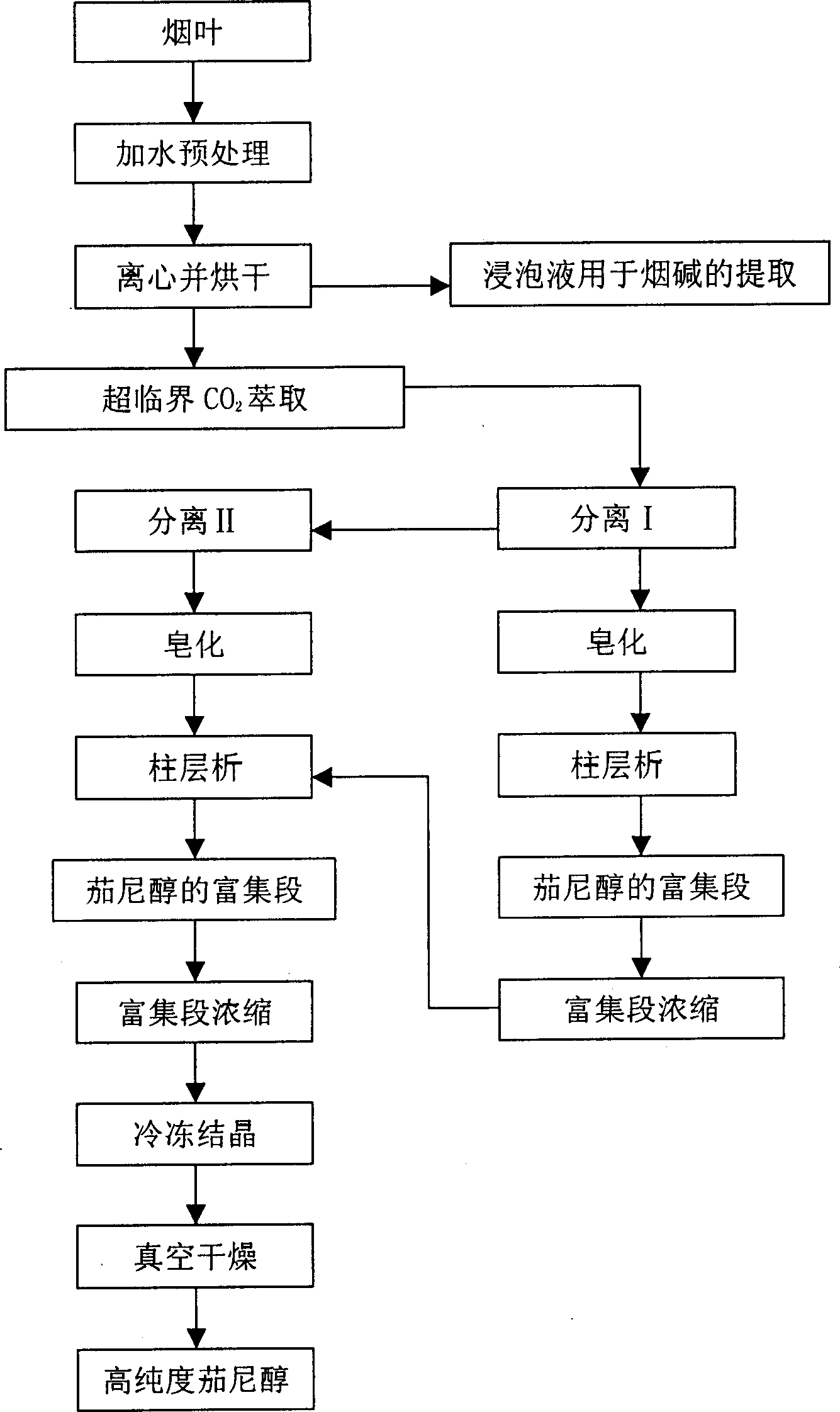

Image

Examples

Embodiment 1

[0017] Example 1: Weigh 100 g of waste tobacco leaves, crush the tobacco leaves to 40 meshes, soak them in water for 5 hours, remove the leaching solution with a centrifuge, and place the treated tobacco leaves at 50° C. to dry. The leachate is collected and reserved for the extraction of nicotine.

[0018] Mix the treated tobacco leaves with 120ml of entrainer, put them into a 1L extraction kettle, and soak for 30 minutes. Set the temperature in the extraction tank to 40°C, the temperature of the separation tank I and the separation tank II is the same as the temperature of the extraction tank, when the temperature reaches the set value, open the inlet valve to feed CO 2 , CO 2 The flow rate is 0.2L / min, and the extraction pressure of the extraction tank is adjusted to 25MPa. The pressures of the separation tank I and the separation tank II are respectively 8MPa and 6MPa. The extraction is carried out every 30 minutes, and the extracts in each separation tank are collected s...

Embodiment 2

[0022] Example 2: Weigh 100 g of waste tobacco leaves, crush the tobacco leaves to 50 meshes, soak them in water for 8 hours, remove the leaching solution with a centrifuge, and place the treated tobacco leaves at 60° C. to dry. The leachate is collected and reserved for the extraction of nicotine.

[0023] Mix the treated tobacco leaves with 120ml of entrainer, put them into a 1L extraction kettle, and soak for 35 minutes. Set the temperature in the extraction tank to 40°C, the temperature of the separation tank I and the separation tank II is the same as the temperature of the extraction tank, when the temperature reaches the set value, open the inlet valve to feed CO 2 , CO 2 The flow rate is 0.33L / min, and the extraction pressure of the extraction tank is adjusted to 28mPa. The pressures of the separation tank I and the separation tank II are respectively 9MPa and 7MPa. The extraction is carried out every 40 minutes, and the extracts in each separation tank are collected ...

Embodiment 3

[0027] Example 3: Weigh 100 g of waste tobacco leaves, crush the tobacco leaves to 60 meshes, soak them in water for 10 hours, remove the leaching solution with a centrifuge, and place the treated tobacco leaves at 70° C. to dry. The leachate is collected and reserved for the extraction of nicotine.

[0028] Mix the treated tobacco leaves with 120ml of entrainer, put them into a 1L extraction kettle, and soak for 40 minutes. Set the temperature in the extraction tank to 40°C, the temperature of the separation tank I and the separation tank II is the same as the temperature of the extraction tank, when the temperature reaches the set value, open the inlet valve to feed CO 2 , CO 2The flow rate is 0.4L / min, and the extraction pressure of the extraction tank is adjusted to 30mPa. The pressures of the separation tank I and the separation tank II are respectively 10MPa and 8MPa. The extraction is carried out every 50 minutes, and the extracts in each separation tank are collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com