Combined ore dressing method for waste materials containing low-grade barite

A beneficiation method and barite technology, applied in chemical instruments and methods, wet separation, mechanical material recovery, etc., can solve the problems of high cost, low sorting effect, low output, etc., to reduce emissions and increase resources. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Based on a domestic iron content of 18.05%, BaSO 4 Take the abandoned tailings with a content of 14.02% iron oxide ore as an example.

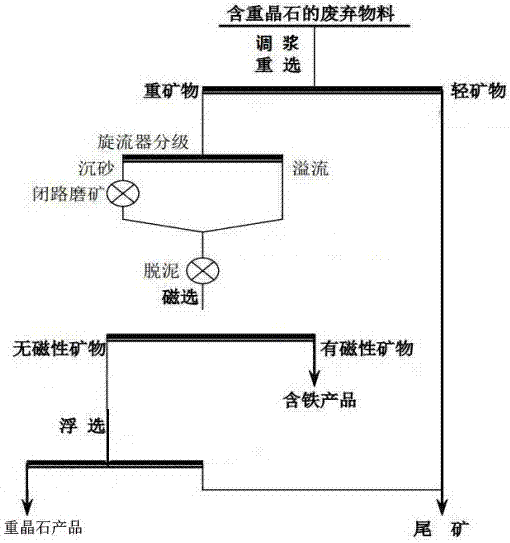

[0026] use as figure 1 Shown the present invention a kind of combined beneficiation method containing low-grade barite waste material, its process steps are as follows:

[0027] (1) Add water to the powdery material to prepare a slurry with a mass concentration of 25%;

[0028] (2) Put the ore pulp obtained in step (1) into the spiral chute for sorting, and obtain two products of heavy minerals and light minerals;

[0029] (3) Mix the heavy minerals obtained in step (2) to a mass concentration of 25%, put them into a cyclone for classification, and obtain a grit-set product and an overflow product with a particle size of less than 325 mesh and a content greater than 90%, and the grit-set product enters the mill Mining equipment for grinding, grinding into grinding products with a particle size of less than 325 mesh and a content grea...

Embodiment 2

[0035] Based on a domestic iron content of 18.05%, BaSO 4 Take the abandoned iron tailings with 14.02% iron oxide ore as an example.

[0036] use as figure 1 Shown the present invention a kind of combined beneficiation method containing low-grade barite waste material, its process steps are as follows:

[0037] (1) Add water to the powdery material to make a slurry with a mass concentration of 40%;

[0038] (2) Put the ore pulp obtained in step (1) into the spiral chute for sorting, and obtain two products of heavy minerals and light minerals;

[0039] (3) Slurry the heavy minerals obtained in step (2) to a mass concentration of 40%, put them into a cyclone for classification, and obtain a grit-set product and an overflow product with a particle size of less than 325 mesh and a content greater than 90%, and the grit-set product enters the mill Mining equipment for grinding, grinding into grinding products with a particle size of less than 325 mesh and a content greater than...

Embodiment 3

[0045] Based on a domestic iron content of 32%, BaSO 4 Take the abandoned tailings of iron oxide-depleted ore with a content of 8.2% as an example.

[0046] use as figure 1 Shown the present invention a kind of combined beneficiation method containing low-grade barite waste material, its process steps are as follows:

[0047] (1) Add water to the powdery material to prepare a slurry with a mass concentration of 33%;

[0048] (2) Put the ore slurry obtained in step (1) into a shaker for sorting to obtain two products, heavy minerals and light minerals;

[0049] (3) Slurry the heavy minerals obtained in step (2) to a mass concentration of 33%, put them into a cyclone for classification, and obtain a grit product and an overflow product with a particle size of less than 325 mesh and a content greater than 90%, and the grit product enters the mill Mining equipment for grinding, grinding into grinding products with a particle size of less than 325 mesh and a content greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com