Mist catching separation device

A separation device and cleaning device technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems affecting the efficient operation of evaporation equipment, poor vapor-liquid separation effect, and affecting process yield, etc., to achieve strong resistance Blockage, prolong the service life of equipment, widen the effect of the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

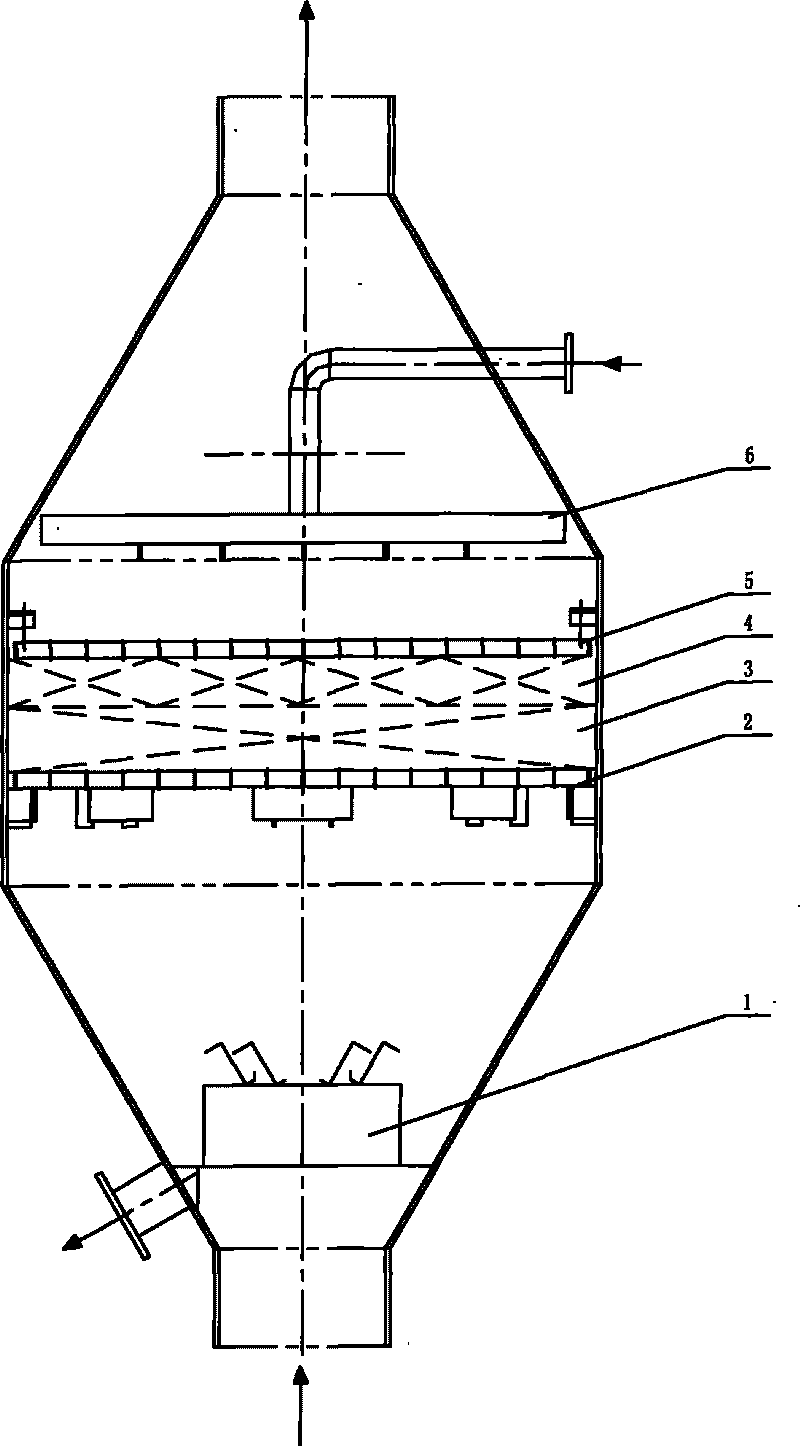

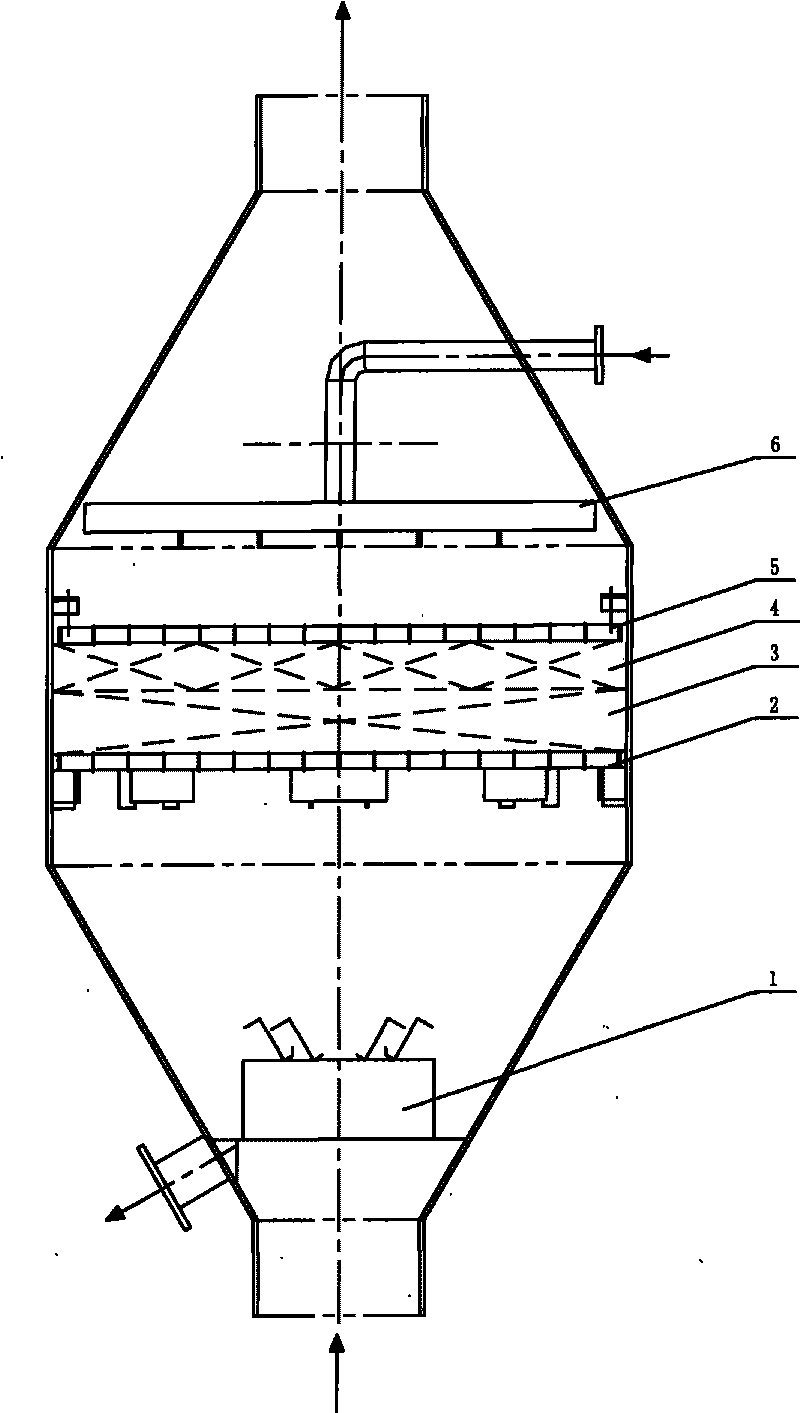

[0016] see figure 1 , The present invention is a foam trap separation device, including pressure grid 5, trap foam screen 4, plate coalescing filler 3 and support frame 2. The foam-catching and separating part is composed of the foam-catching wire mesh 4 and the plate-type coalescing packing 3. The foam-catching and separating part is provided with a support frame 2 and a pressure grid 5 is arranged above the foam-catching and separating part. The foam-catching and separating part is pressed on the support frame 2 and the pressure grid. 5, each component is manufactured in blocks and installed in blocks.

[0017] For systems that are prone to crystallization, adhesion, or electrolytic corrosion of the foam collection and separation parts, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com