Reaction device and method for adiponitrile production

A reaction device, technology of adiponitrile, applied in ammonia-carboxylic acid reaction preparation, carboxylic acid nitrile purification/separation, sustainable manufacturing/processing, etc., can solve problems such as high liquid-gas ratio, interface impact, increased production cost, etc. , to achieve the effect of improving conversion rate and preliminary separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

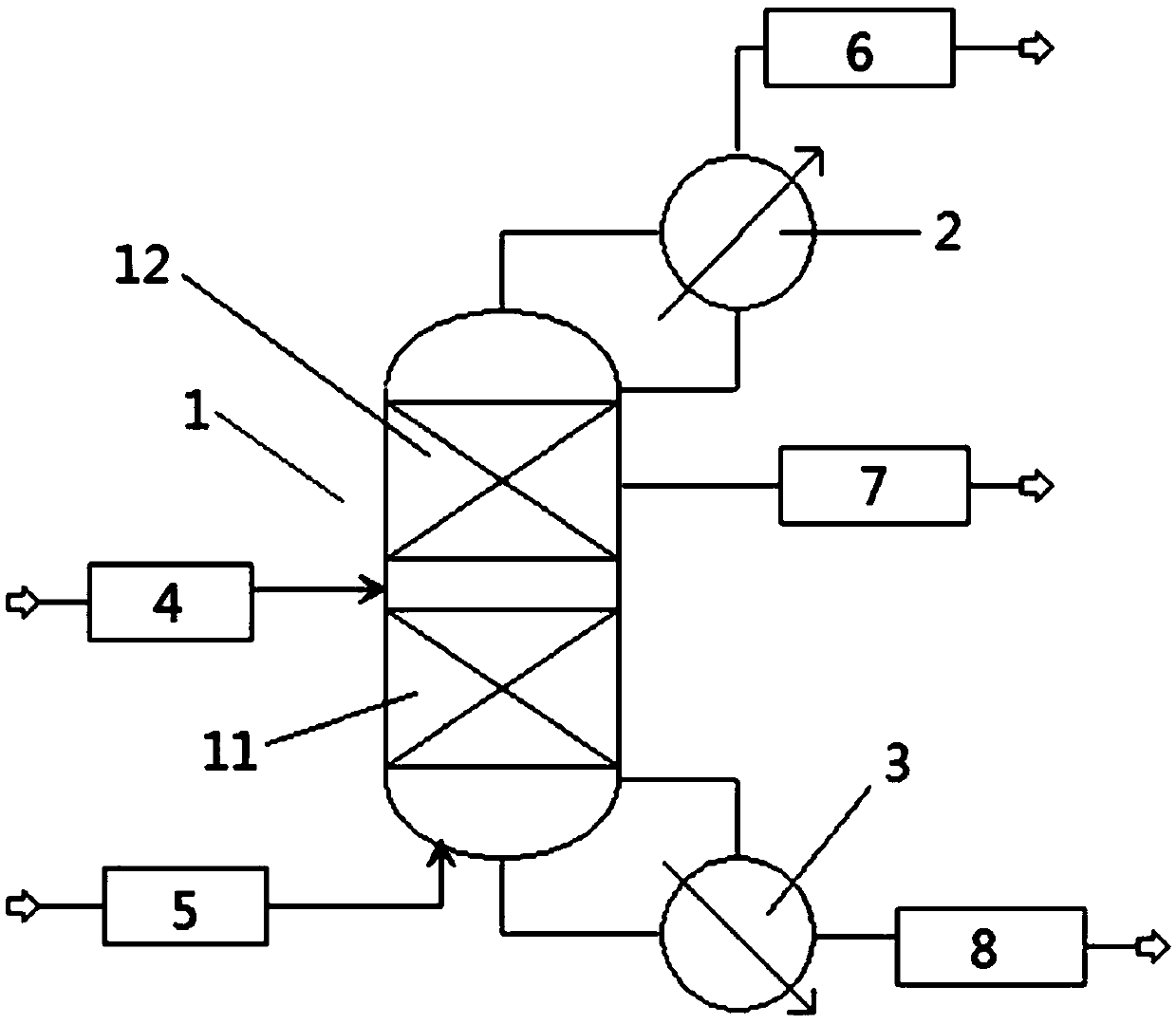

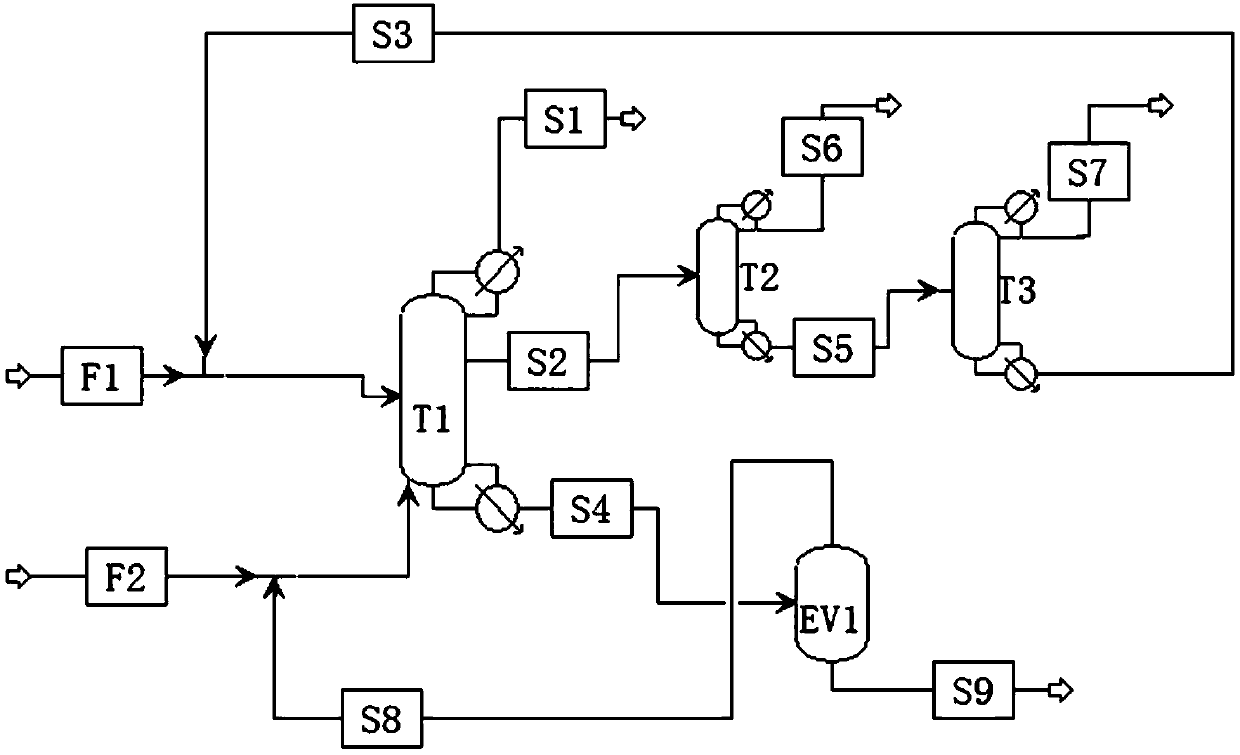

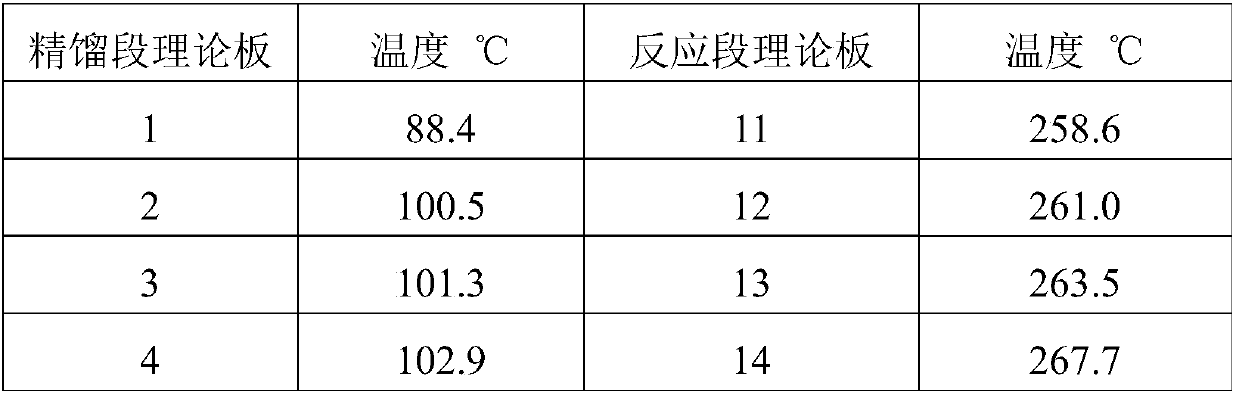

[0034] There are 20 theoretical plates in the reactive distillation column, and the first feed port is above the 11th theoretical plate; 1-10 theoretical plates are the rectification section, with ceramic packing, and the second material outlet is located on the 5th theoretical plate; 11-20 The theoretical plate is in the form of a guide sieve plate in the reaction section; the operating pressure at the top of the tower is 1.8 atm in a stable operating state, and the temperature at each theoretical plate position is shown in Table 1. The first feed port is fed with 1 kmol / h of liquid adipic acid, diluted Phosphoric acid catalyst of agent 3kmol / h and 0.2% (mass percentage), the second inlet feeds into vapor phase ammonia 10kmol / h and diluent 2kmol / h, the first discharge outlet produces water vapor 4kmol / h and ammonia The mixed steam of 8kmol / h, the ratio of the liquid phase of the reaction system taken from the second discharge port is 67% (volume percentage), and the remaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com