Microalloyed high-silicon-manganese nitrogen-containing austenitic stainless steel material and preparation method

A high silicon-manganese type, stainless steel technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve problems such as hindering popularization and application, inability to produce, etc., achieve good horizontal and vertical strength and toughness matching ratio and wear resistance, and improve alloy production. High efficiency and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

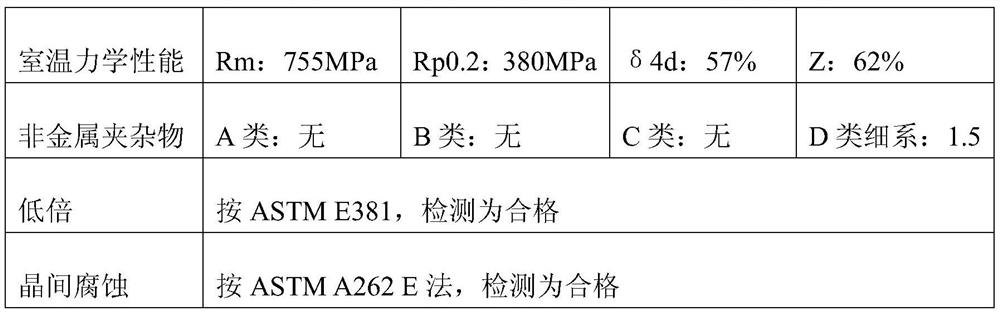

Embodiment 1

[0026] The electroslag remelting electrode rod of high silicon manganese nitrogen-containing stainless steel has a unit weight of 450kg and a total of 900kg. Using a 500kg vacuum induction furnace, according to C: 0.045%, Cr: 16.8%, Ni: 8.5%, Si: 3.9%, Mn: 8.3%, N: 0.15%, Fe: 61.5%, Mo: 0.3%, V: 0.15 %, Nb: 0.1%, Cu: 0.1% composition ratio, Fe, Cr, Ni, Mo, Nb are used as primers, placed at the bottom of the crucible, C, Si, Mn, Cu, iron vanadium master alloy, micro Small materials such as carbon ferrochrome are placed in the hopper.

[0027] After the base material is completely melted, add small materials in batches under a protective atmosphere, and cast into cylindrical electrode rods after passing the component test. The diameter of the electrode rods is Φ260mm, 2 pieces. After the surface of the rod is sanded and finished, a remelting electrode rod for electroslag remelting is obtained.

[0028] The electroslag remelting slag system of high-silicon-manganese nitrogen-co...

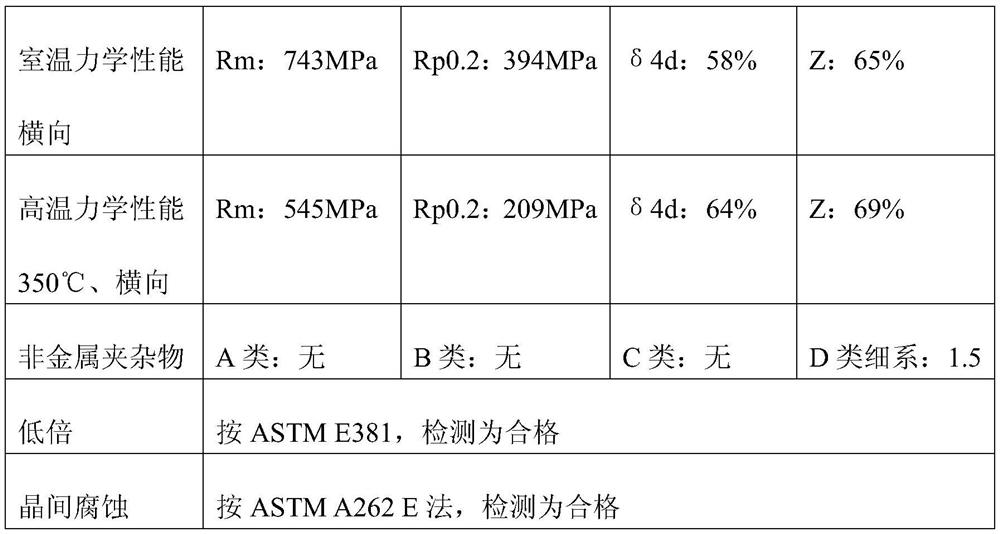

example 2

[0037]The electroslag remelting electrode rod of high silicon manganese nitrogen-containing stainless steel has a unit weight of 1300kg and a total of 2600kg. Using 3000kg vacuum induction furnace, according to C: 0.042%, Cr: 17.0%, Ni: 8.3%, Si: 3.95%, Mn: 8.10%, N: 0.14%, Fe: 61.2%, Mo: 0.5%, V: 0.13 %, Nb: 0.15%, Cu: 0.25% composition ratio, Fe, Cr, Ni, Mo, Nb are used as primers, placed at the bottom of the crucible, C, Si, Mn, Cu, iron vanadium master alloy, micro Small materials such as carbon ferrochrome are placed in the hopper.

[0038] After the base material is completely melted, add small materials in batches under a protective atmosphere, and cast into cylindrical electrode rods after passing the component test. The diameter of the electrode rods is Φ400mm, 2 pieces. After the surface of the rod is sanded and finished, a remelting electrode rod for electroslag remelting is obtained.

[0039] The electroslag remelting slag system of high-silicon-manganese nitroge...

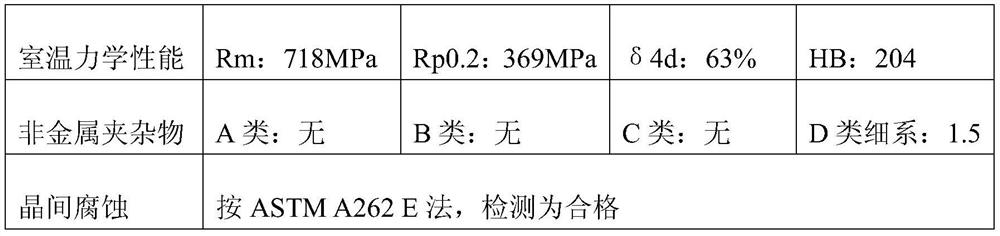

Embodiment 3

[0048] The electroslag remelting electrode rod of high silicon manganese nitrogen-containing stainless steel has a unit weight of 450kg and a total of 900kg. Using a 500kg vacuum induction furnace, according to C: 0.040%, Cr: 16.7%, Ni: 8.3%, Si: 4.1%, Mn: 7.9%, N: 0.16%, Fe: 62.1%, Mo: 0.3%, V: 0.1 %, Nb: 0.12% composition ratio, Fe, Cr, Ni, Mo, Nb are used as primers, placed at the bottom of the crucible, C, Si, Mn, Cu, iron vanadium master alloy, micro-carbon ferrochrome and other small Put the material in the hopper.

[0049] After the base material is completely melted, add small materials in batches under a protective atmosphere, and cast into cylindrical electrode rods after passing the component test. The diameter of the electrode rods is Φ200mm, and there are 4 pieces. After the surface of the rod is sanded and finished, a remelting electrode rod for electroslag remelting is obtained.

[0050] The electroslag remelting slag system of high-silicon-manganese nitrogen-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com