Method for separating multi-element alloy of lead, bismuth, gold, silver and copper

A multi-element alloy and lead separation technology, applied in the direction of improving process efficiency, can solve the problems of cumbersome processing process and large loss of gold and silver.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

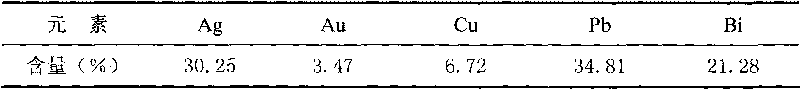

[0012] Embodiment 1: See Table 1 for the material composition used in the test.

[0013] Table 1 Raw material main component weight percent

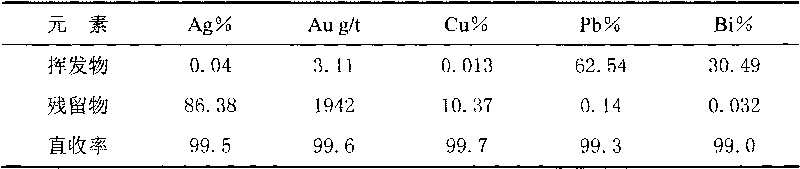

[0014]

[0015] Put 2000g of raw material lead, bismuth, gold, silver and copper multi-element alloy into graphite crucible and place it in a vacuum furnace, pump the vacuum in the furnace to 10Pa, start to heat up at a rate of 5°C / min, when the temperature in the furnace rises to the melting point of the raw material 450 ℃, keep the temperature constant for 30 minutes, then raise the temperature to 950 ℃ at a rate of 15 ℃ / min, continue to heat up to 1100 ℃ after 10 minutes of constant temperature, constant temperature distillation and separation for 60 minutes, and the volatilized lead and bismuth vapor continuously escapes from the liquid alloy and is collected in the condensation tray. Turn off the power and start to cool down, continue to ensure the vacuum in the furnace to prevent the material from being oxidized. When the temper...

Embodiment 2

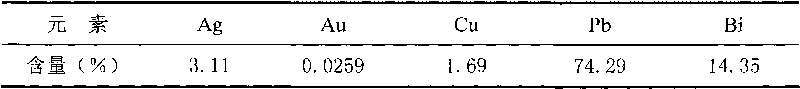

[0020] Table 3 Material main component weight percentage

[0021]

[0022] The specific implementation steps are as follows:

[0023] Put 2000g of raw material lead, bismuth, gold, silver and copper multi-element alloy into graphite crucible and place it in a vacuum furnace, pump the vacuum in the furnace to 5Pa, start to heat up at a rate of 5°C / min, when the temperature in the furnace rises to the melting point of the raw material at 350 ℃, keep the constant temperature for 40 minutes, then raise the temperature to 900 ℃ at a rate of 15 ℃ / min, continue to raise the temperature to 1050 ℃ after 15 minutes, and continue to heat up to 1050 ℃, constant temperature distillation and separation for 80 minutes, the volatilized lead and bismuth vapor continuously escapes from the liquid alloy and enters the condensation tray Turn off the power and start to cool down. Continue to ensure the vacuum in the furnace to prevent the material from being oxidized. When the temperature in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com