High-hardness 3J40 alloy bar for air valve and manufacturing method of high-hardness 3J40 alloy bar

A technology for alloy rods and manufacturing methods, which is applied in the field of high-hardness 3J40 alloy rods for air valves and its manufacturing field, which can solve problems such as not being able to meet the requirements of high-end customers, achieve excessive stress prevention, uniform billet structure, and reduce residual The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, two batches of high-hardness 3J40 alloy bars for gas valves were produced, all of which went through batching→vacuum induction melting→casting electrodes→hot annealing→electrode surface treatment→protective atmosphere electroslag smelting→steel ingot diffusion annealing→forging blanking→ Grinding → forging finished product → solution heat treatment → straightening and polishing → non-destructive inspection.

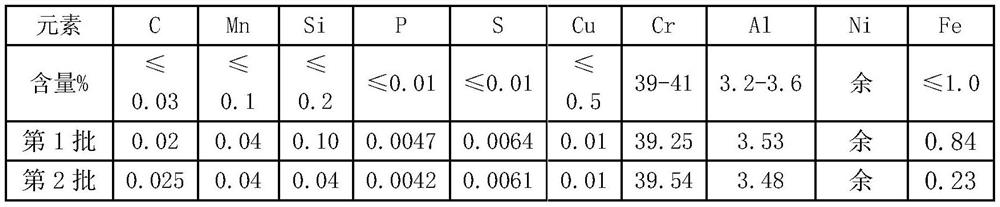

[0033] The steel ingots of the examples obtained by smelting were subjected to homogenization annealing to obtain steel ingots with uniform composition and good plasticity. The chemical composition of the steel ingots obtained is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com