Method for preparing composite of grapheme with different oxidation degrees and manganese dioxide

A technology of manganese dioxide and oxidation degree, which is applied in capacitors, circuits, electrolytic capacitors, etc., can solve the problems that the application of graphene and nano-manganese dioxide composite electrodes has not been found, and achieve obvious supercapacitive performance, low energy consumption, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

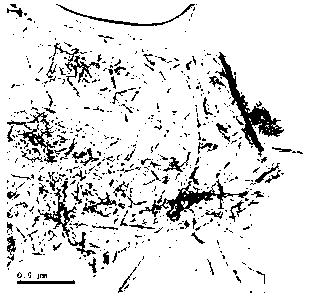

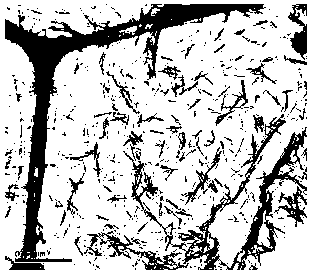

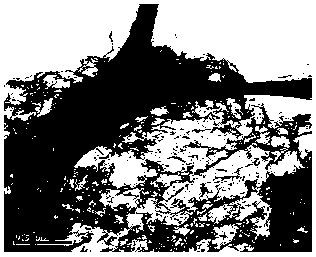

Image

Examples

Embodiment 1

[0023] Step 1: Pour 120mL of concentrated sulfuric acid with a mass fraction of 98% into a beaker containing 3g of raw graphite, and stir for 15min under ice bath conditions; slowly add 15gKMnO to the mixture 4 And keep the temperature not higher than 4°C. After the addition, stir in an ice bath for 2 hours; move the mixture to a 35°C water bath and continue stirring for 1 hour, then raise the temperature to 60°C and keep it for 30 minutes. Slowly add 250mL of deionized water to the mixture to control The dropping speed keeps the temperature of the system at 60±3°C; take it out after stirring for 15 minutes after adding, stir at room temperature and quickly add 500mL deionized water and 30mLH 2 o 2 , the reaction was terminated after stirring for 15 min, and a golden yellow suspension was obtained. The sulfate ions were removed by centrifugal washing with 10% dilute hydrochloric acid, dried at 60 °C for 24 h, and ground to obtain GO powder.

[0024] Step 2: Take 0.1 g of GO ...

Embodiment 2

[0027] Step 1: Prepare graphite oxide as in Step 1 in Example 1.

[0028] Step 2: Take 0.1 g of GO powder prepared in Step 1 and add it to 100 mL of deionized water, sonicate for 2 hours to obtain a uniformly dispersed 1 mg / mL graphite oxide solution, transfer the solution to a round bottom flask, add 100 μL of hydrazine hydrate, shake well, and put Reflux in a water bath furnace at 80°C, control the reduction time for 30 minutes, take it out, filter it with suction, wash it, and then ultrasonically disperse it in deionized water to obtain a uniform suspension, and obtain graphene oxide with a large specific surface area by freeze-drying.

[0029] Step 3: weigh the prepared graphene oxide powder 0.066g and MnCl 2 4H 2 O (0.27g) was mixed in 50mL isopropanol and sonicated for 2h, the dispersed mixed solution was placed in a water bath at 80°C and stirred, and 5mL dissolved in 0.15g KMnO was quickly poured into it. 4 deionized water, reflux for 30min, take out suction filtrati...

Embodiment 3

[0031] Step 1: Prepare graphite oxide as in Example 1.

[0032] Step 2: Take 0.1 g of GO powder prepared in Step 1 and add it to 100 mL of deionized water, sonicate for 2 hours to obtain a uniformly dispersed 1 mg / mL graphite oxide solution, transfer the solution to a round bottom flask, add 100 μL of hydrazine hydrate, shake well, and put Reflux in a water-bath furnace at 80°C, control the reduction time for 1 hour, take it out, filter it with suction, wash it, and then ultrasonically disperse it in deionized water to obtain a uniform suspension, and obtain graphene oxide with a large specific surface area by freeze-drying.

[0033] Step 3: weigh 0.066g of graphene oxide powder prepared in step 2 and MnCl 2 4H 2 O (0.27g) was mixed in 50mL isopropanol and sonicated for 2h, the dispersed mixed solution was placed in a water bath at 80°C and stirred, and 5mL dissolved in 0.15g KMnO was quickly poured into it. 4 deionized water, reflux for 30min, take out suction filtration, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com