Aluminum oxide/nickel-titanium alloy/aluminum oxide composite material prepared through diffusion bonding and method thereof

A technology of nickel-titanium alloy and composite material, which is applied in the field of alumina/nickel-titanium alloy/alumina composite material to achieve the effects of high efficiency, excellent mechanical properties and uniform diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 1 mm thick Ni-Ti alloy sheet was placed on two Al 2 o 3 Sandwich-structured samples in ceramic plates;

[0040] Then, place it in a graphite mold, fasten it with a constant torque wrench, apply a pressure of 1 kPa, and anneal it in a vacuum carbon tube furnace with argon gas at a reaction temperature of 1250° C., and keep it warm for 2 hours.

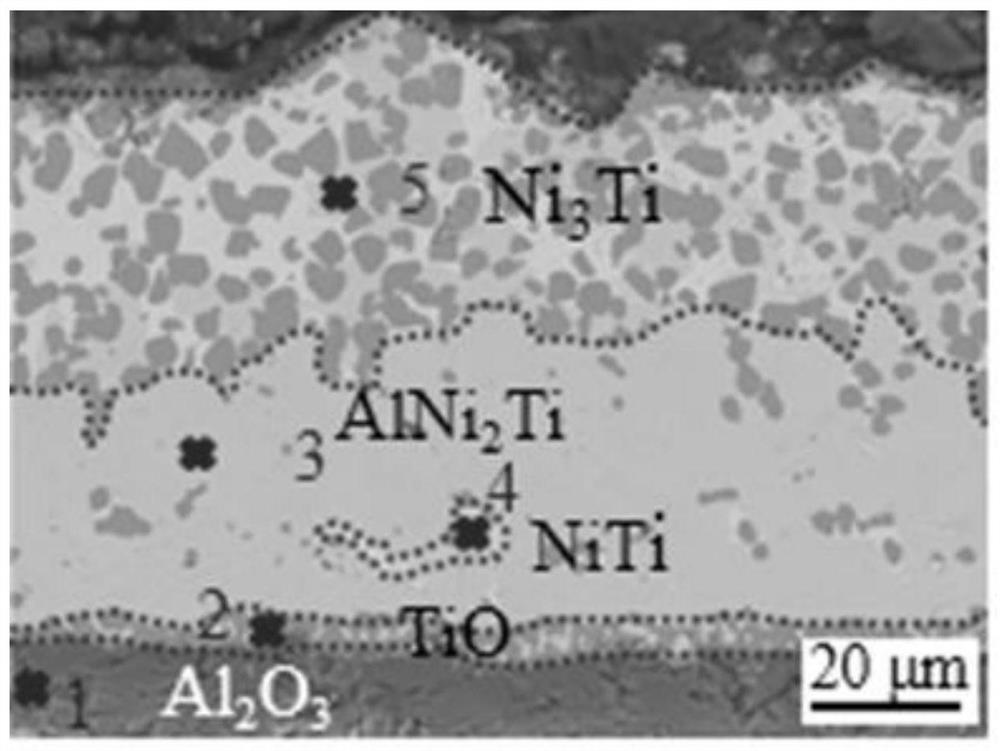

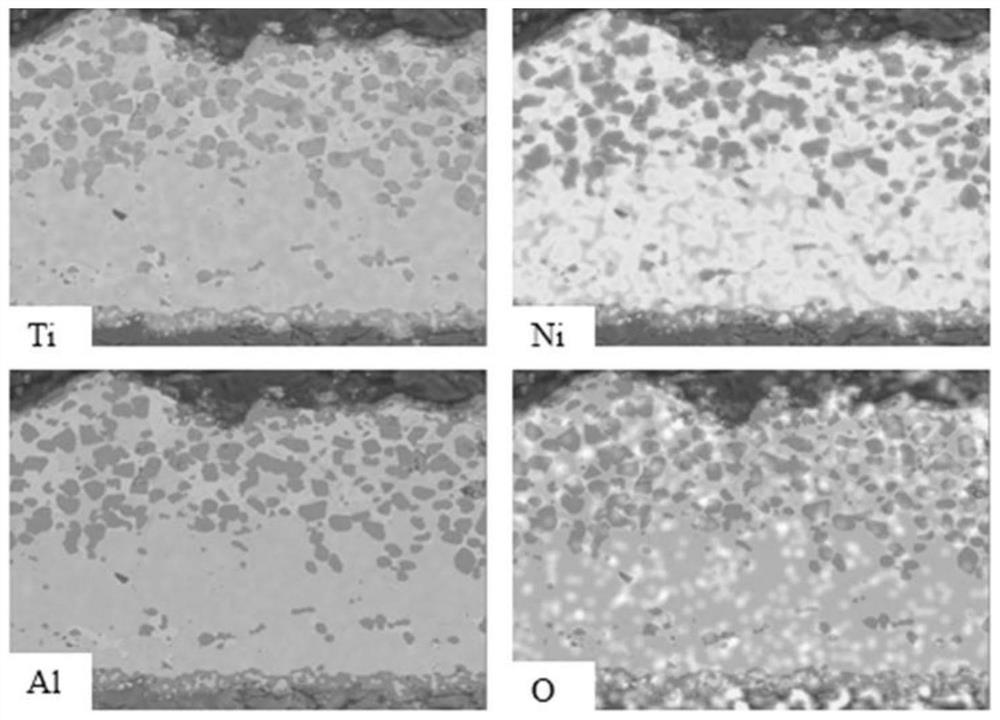

[0041] see figure 1 and figure 2, the sample was cut along the direction perpendicular to the interface, and the interface was tested by SEM and EDS. The results show that the nickel-titanium alloy reacts chemically with alumina to form AlNi 2 For Ti and TiO, the thickness of the interface layer is 20 μm and 18 μm respectively, the interface layer is relatively thin, and no continuous interface layer is formed.

Embodiment 2

[0043] A 1 mm thick Ni-Ti alloy sheet was placed on two Al 2 o 3 Sandwich-structured samples in ceramic plates;

[0044] Then, place it in a graphite mold, tighten it with a constant torque wrench, apply a pressure of 2kPa, and anneal it in a vacuum carbon tube furnace with argon gas at a reaction temperature of 1400°C for 4 hours.

[0045] The samples were cut along the direction perpendicular to the interface, and the interface was tested by SEM and EDS. The results show that the nickel-titanium alloy reacts chemically with alumina to form AlNi 2 For Ti and TiO, the interface layer thicknesses are 22 μm and 4 μm.

Embodiment 3

[0047] A 1 mm thick Ni-Ti alloy sheet was placed on two Al 2 o 3 Sandwich-structured samples in ceramic plates;

[0048] Then, place it in a graphite mold, tighten it with a constant torque wrench, apply a pressure of 4kPa, and anneal it in a vacuum carbon tube furnace with argon gas, and keep it warm for 6h.

[0049] The samples were cut along the direction perpendicular to the interface, and the interface was tested by SEM and EDS. The results show that the nickel-titanium alloy reacts chemically with alumina to form AlNi 2 For Ti and TiO, the interface layer thicknesses are 18 μm and 14 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com