Production technology of Mg 9995B and above protogenetic magnesium ingot

A technology of mg9995b and 1.mg9995b, which is applied in the production process of Mg9995B and above primary magnesium ingots, can solve the problems of no production process, unfavorable, and no mass production scale, and achieve the effect of improving purity and reducing impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific implementation, which is an explanation of the present invention rather than a limitation.

[0027] 1. Analysis of influencing factors of metal magnesium reduction

[0028] 1.1 Analysis of Factors Affecting Raw and Auxiliary Materials Components

[0029] The main raw and auxiliary materials for metal magnesium reduction are: dolomite, ferrosilicon, and fluorite powder.

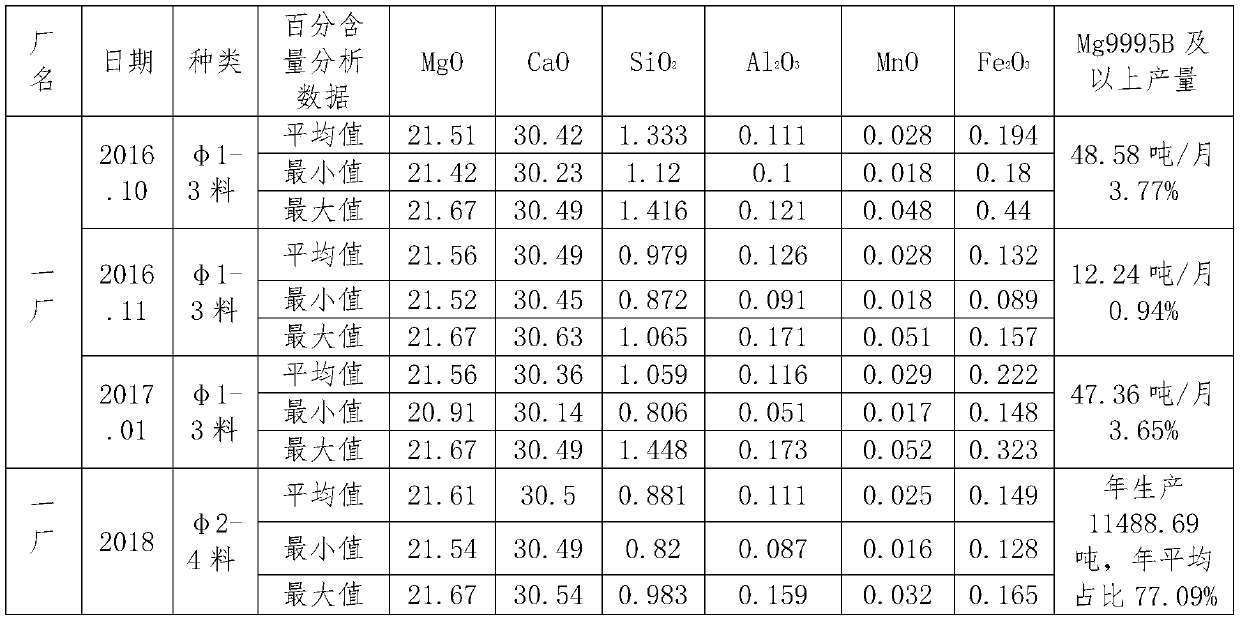

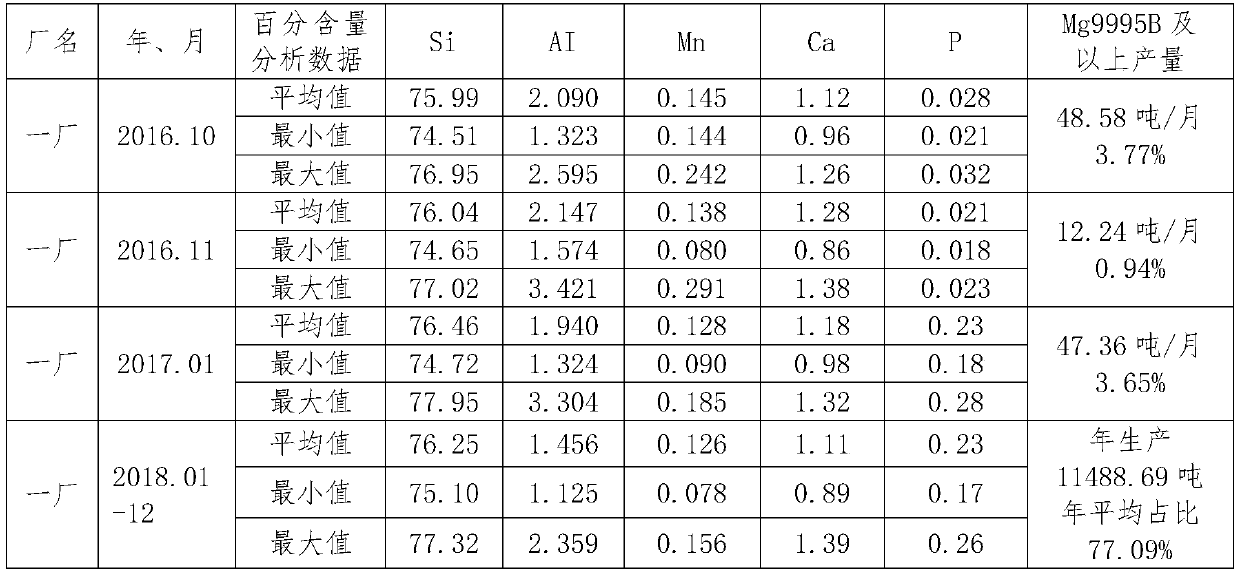

[0030] 1.1.1 Dolomite

[0031] In the test process of the present invention, the chemical composition of dolomite, the main raw material of metal magnesium, is analyzed. During the first Mg9995B test from October 2016 to January 2017, the testers analyzed and controlled the impurity components in the chemical composition of dolomite, such as silicon dioxide, aluminum oxide, and manganese oxide, to find out the maximum value and The minimum value is analyzed to evaluate its influence factor on the production o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com