Thermal conductive aluminum alloy, and preparation method and application thereof

An aluminum alloy and mixed rare earth technology, which is applied in the field of heat-conducting aluminum alloy and its preparation, can solve the problems of unsatisfactory thermal conductivity, low hardness of pure aluminum, and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

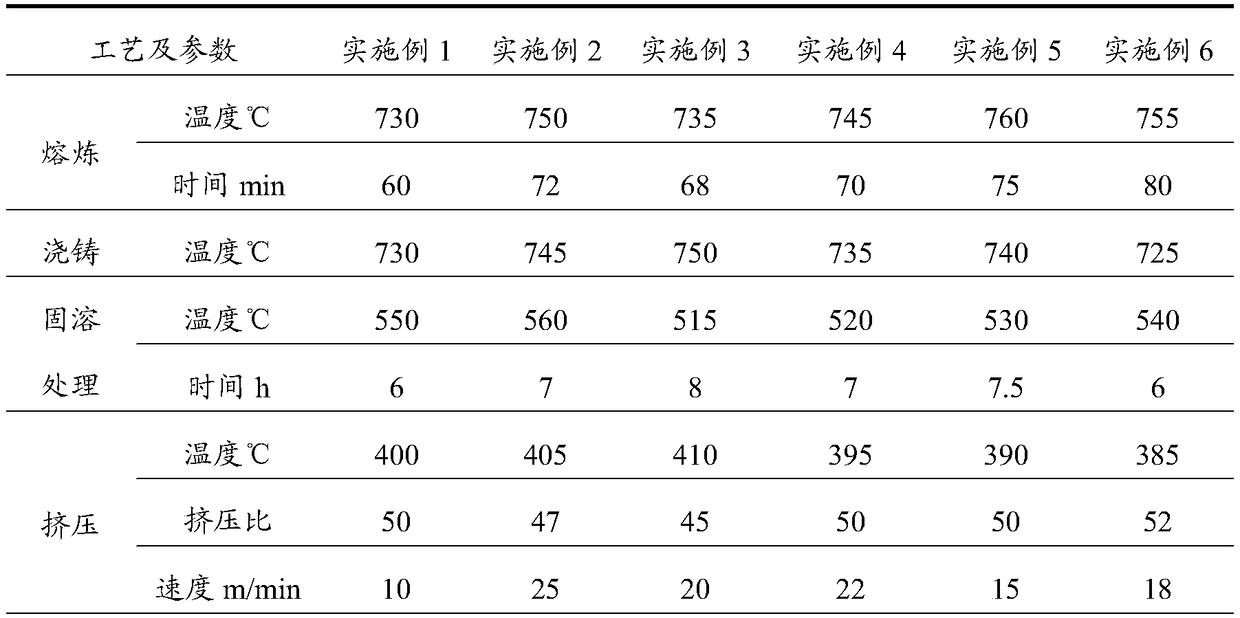

[0033] The present invention provides a method for preparing a heat-conducting aluminum alloy described in the above technical solution, comprising the following steps:

[0034] (1) Melting the raw materials including the corresponding components of the heat-conducting aluminum alloy described in the above technical solution to obtain the aluminum alloy liquid;

[0035] (2) casting the aluminum alloy liquid obtained in the step (1), and obtaining an ingot after cooling;

[0036] (3) performing solution treatment on the ingot obtained in the step (2) to obtain a homogenized aluminum alloy; the temperature of the solution treatment is 510-560° C., and the holding time of the solution treatment is 6-8 hours;

[0037] (4) Extruding the homogenized aluminum alloy obtained in the step (3) to obtain an extruded material; the temperature of the extrusion is 380-420°C; the extrusion ratio of the extrusion is 45-55;

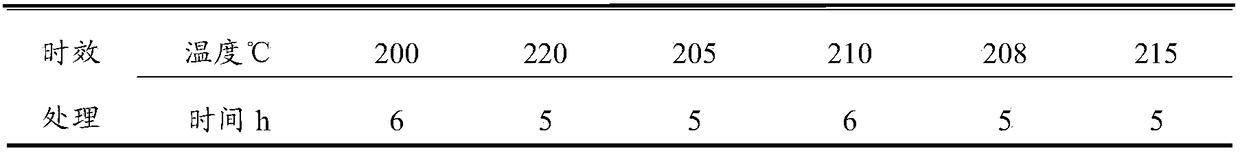

[0038] (5) aging the extruded material obtained in the step (4) to o...

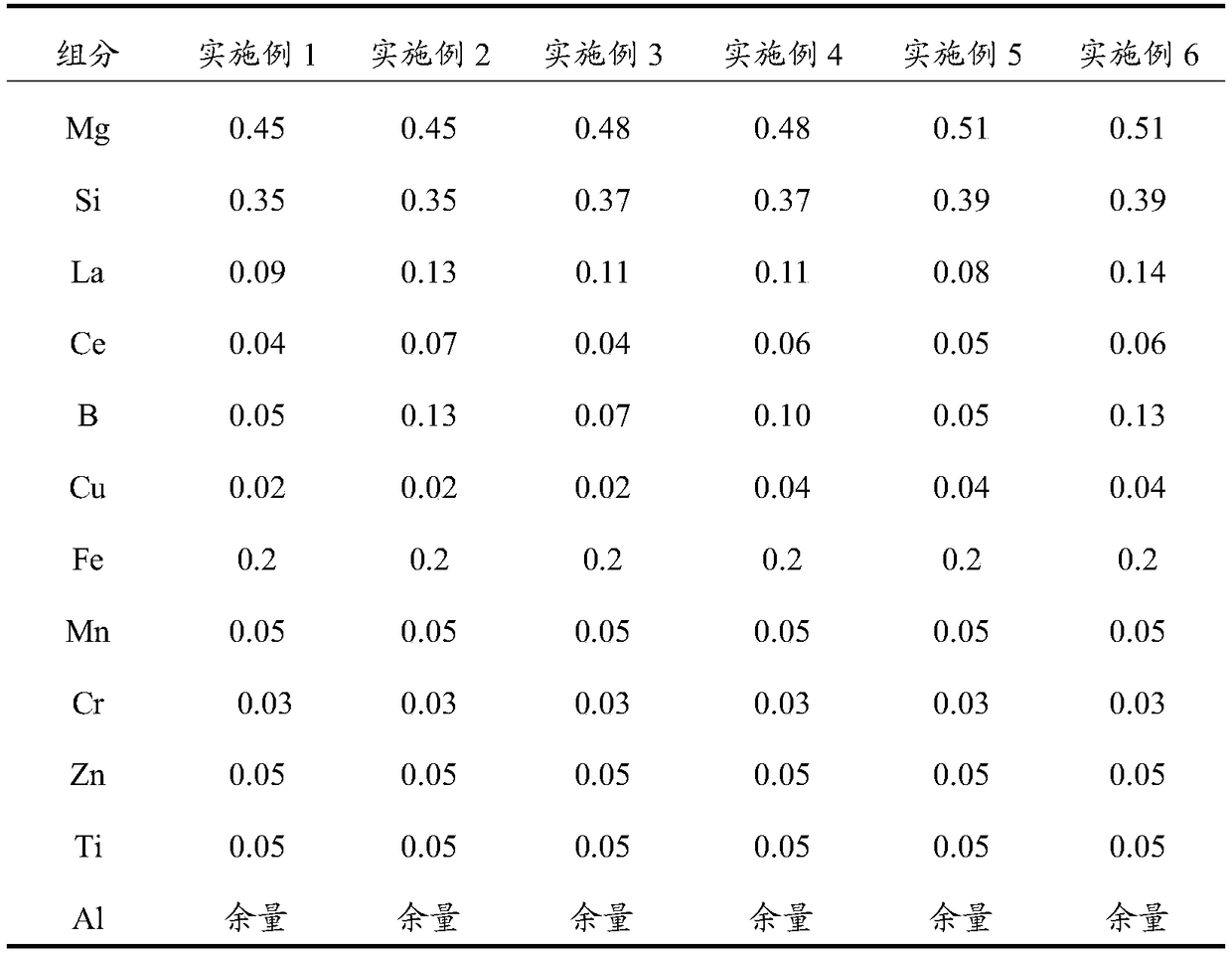

Embodiment 1

[0071] Prepare the raw materials according to the contents shown in Table 1, and then prepare the heat-conducting aluminum alloy in the following manner: Among them, the auxiliary agent used in the smelting process is: refining agent C 2 Cl 6 , the amount added is 0.3% of the mass of molten aluminum; the covering agent is: 55% NaCl+45% KCl, the amount added is 0.3% of the mass of molten aluminum; the coating is: ZnO: 20%, Na 2 SiO 3 :10%, H 2 O margin.

[0072] Add industrial pure aluminum into the graphite crucible, heat until the pure aluminum melts, then add the aluminum-silicon master alloy ingot, after the aluminum-silicon master alloy is melted, add a covering agent to protect the melt, continue heating; stir the melt to make the temperature uniform, When the temperature reaches 730°C, press the aluminum-boron intermediate alloy into the molten aluminum with a carbon cover, stir at a slow speed for 5 minutes, add the covering agent, adjust the temperature to 730°C and...

Embodiment 2~6

[0076] The thermally conductive aluminum alloy was prepared according to the method of Example 1, the difference lies in the composition and the specific preparation process, which are listed in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com