Method and device for separating 434 aluminum alloy composite plates

A composite plate, aluminum alloy technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the difficulty of increasing the process of removing impurity alloy elements, the inability of the cladding layer and the core layer to be uniformly combined, and the content of melt components. Large changes and other problems, to achieve the effect of less oxidation, low heating temperature, uniform and constant temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

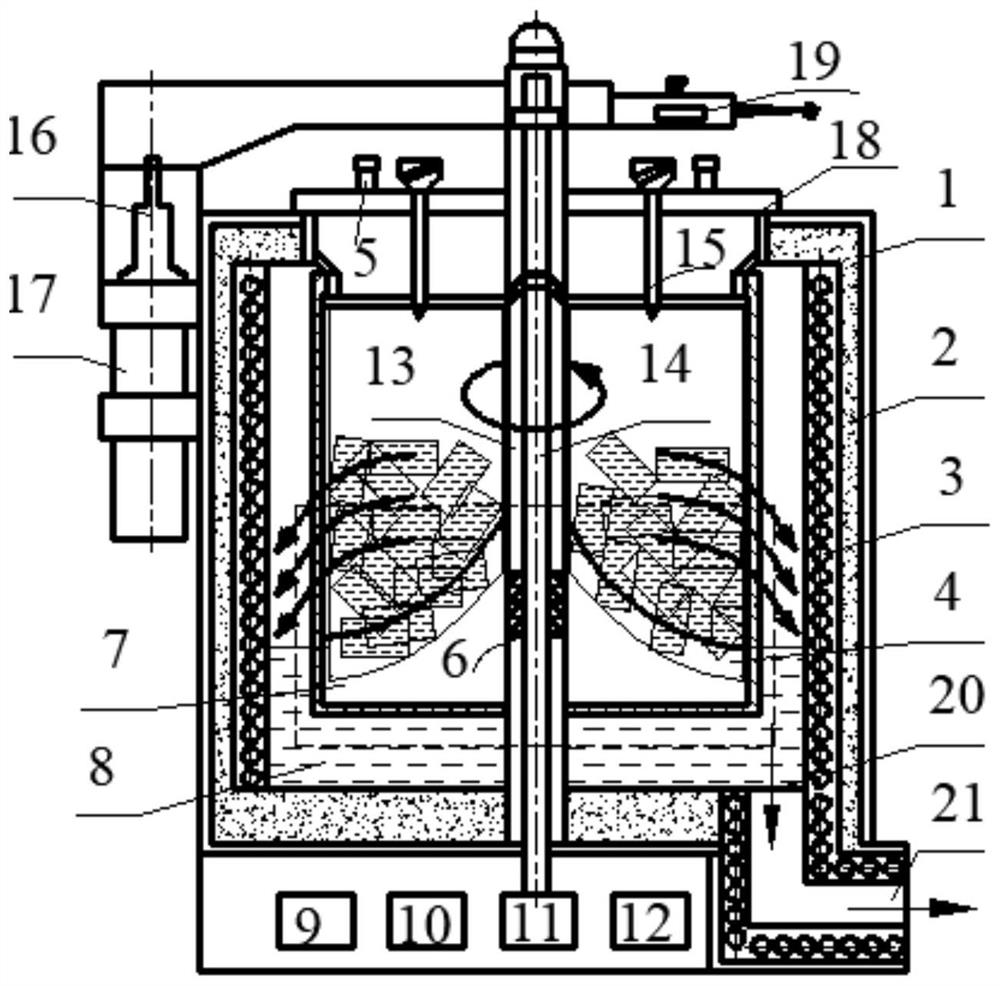

[0051] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: A method for separating 434 aluminum alloy composite panels in this embodiment is implemented according to the following steps:

[0052] 1. Turn on the high-temperature centrifuge PID furnace temperature self-regulating system (10) to set temperature parameters, and further increase the temperature to 574-643°C;

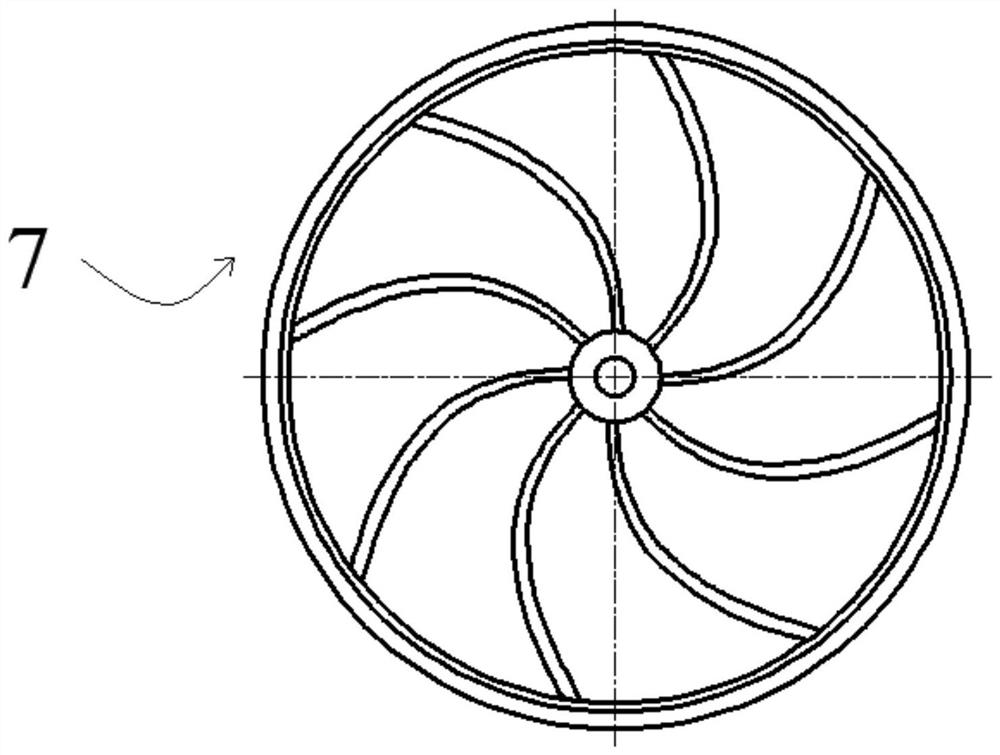

[0053] 2. Add the pretreated 434 aluminum alloy clad plate into the high-temperature centrifuge centrifuge barrel (7), heat it to 574-643 °C for heat preservation, and melt the cladding layer of the 434 aluminum alloy clad plate into a molten liquid;

[0054] 3. Set the centrifugal parameters of the centrifugal mechanism (11), and start centrifuging to separate out the melt;

[0055] 4. After centrifuging for a period of time, the liquid discharge mechanism (12) adjusts the movable baffle (20) to discharge the melt in the melt deposition tank (8), and then discharges the 4004 aluminum alloy melt through the li...

specific Embodiment approach 1

[0072] Embodiment 1: "Pour out the unmelted core layer alloy into the smelting furnace 2 with the feeding and discharging mechanism (9)" can be to put the charge into the tooling (4), and use a manipulator to put in and take out, and do not use feeding and discharging. Agency (9).

specific Embodiment approach 2

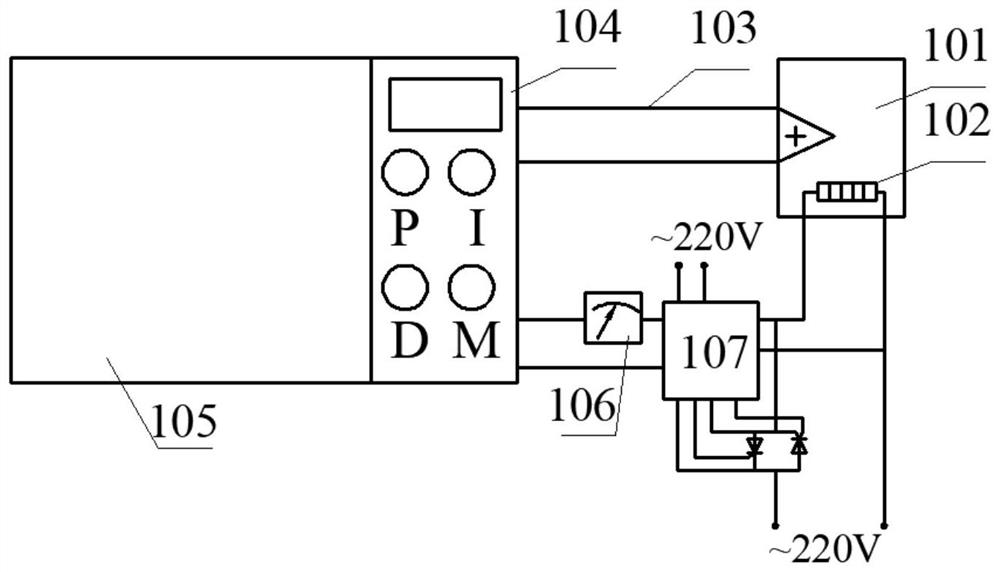

[0073] Embodiment 2: The PID furnace temperature self-regulating system (10) measures the furnace temperature through the thermocouple (15) and corrects it with the compensation wire (103) and displays the real furnace temperature on the display recorder (105), (107) thyristor regulator The output power of the furnace is automatically adjusted by the change of the reading on the ammeter (106), and then the furnace temperature is adjusted. If there is still a deviation in the reading of the ammeter (106), it is manually adjusted through the PID adjustment control board (104).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com