Iron-rich phase modifier as well as preparation method and modification method thereof

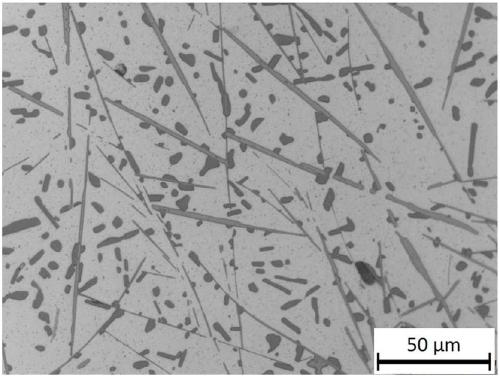

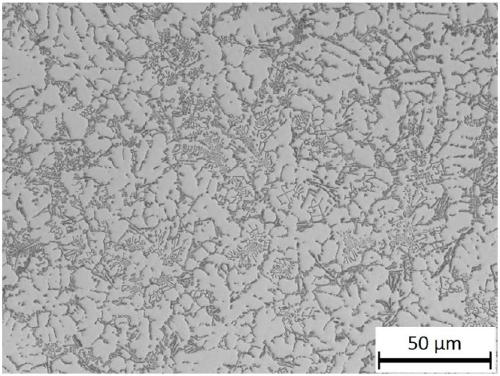

A modification agent and iron-rich technology, which is applied in the field of iron-rich phase modification, can solve the problems that the needle-shaped iron-rich phase cannot be eliminated, the volume fraction of the iron-rich phase is increased, and the amount of addition is not recognized, so as to achieve the refinement of the iron-rich phase, The effect of reducing impurity elements and reducing the content of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a preparation method of the above-mentioned iron-rich phase modifier, including:

[0023] Put the Al alloy, Al-Si alloy, Al-Fe alloy and Al-Mn alloy in the aluminum alloy melting furnace according to the ratio, and raise the temperature to 800-900°C. Then after all the alloys are melted, the temperature is lowered to 720-750°C, and the Al-B master alloy prepared and wrapped with aluminum foil is pressed into the aluminum melt with a titanium tool.

[0024] After the Al-B intermediate alloy is completely melted, the melt is degassed and impurity-removed, and after 10 to 30 minutes of heat preservation, the slag is removed and cast into a round ingot to obtain a high volume fraction of Al(MnFe)Si4. Elemental alloys are modifiers.

[0025] The above-prepared ingot wagon is cut into sections, subjected to homogenization treatment at 500-550° C., and then hot-extruded to prepare an alloy rod with a diameter of 9.5 mm.

[002...

Embodiment 1

[0032] This embodiment provides an iron-rich phase modifier, which is mainly prepared through the following steps:

[0033] The alloy composition is configured according to weight percentage, including: Si 7.0%, Fe 2.5%, Mn 0.7%, B 0.05%, and the balance of Al.

[0034] Preparation of modifier: first, place the prepared 4 raw materials such as Al, Al-Si, Al-Mn, and Al-Fe in an aluminum alloy melting furnace, and raise the temperature to 800°C; then cool down to 720°C after all the alloys are melted. ℃, use a titanium tool to press the Al-B master alloy that has been prepared and wrapped with aluminum foil into the aluminum melt; after the Al-B master alloy is completely melted, degas and remove impurities from the melt, keep it warm and let it stand After 20 minutes, the slag was removed and poured into a round ingot.

[0035] Preparation of modificator: cut the cylindrical ingot car body prepared above into sections, and perform hot extrusion processing after homogenization ...

Embodiment 2

[0037] This embodiment provides an iron-rich phase modifier, which is mainly prepared through the following steps:

[0038] The alloy composition is configured according to weight percentage, including: Si 5.0%, Fe 3.5%, Mn 1.1%, B 0.06%, and the balance of Al.

[0039] Modification agent preparation: first place the prepared Al, Al-Si, Al-Mn, Al-Fe and other four raw materials in the aluminum alloy melting furnace, raise the temperature to 850°C; then cool down to 730°C after all the alloys are melted ℃, use a titanium tool to press the Al-B master alloy that has been prepared and wrapped with aluminum foil into the aluminum melt; after the Al-B master alloy is completely melted, degas and remove impurities from the melt, keep it warm and let it stand After 30 minutes, the slag was removed and poured into a round ingot.

[0040] Preparation of the modificator: Cut the cylindrical ingot car body prepared above into sections, and perform hot extrusion processing after homogeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com