Iron-based amorphous nanocrystalline composite coating and preparation method thereof

A nanocrystalline composite, iron-based amorphous technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problem of weak bonding strength between amorphous coating and substrate, difficulty in coating Thin layer thickness and other problems, to achieve the effect of easy operation, good coating formation and little splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of alloy powder for plasma surfacing:

[0030] The pure metal Fe, Cu, Si, Mn used in industry and Fe-Ni, Fe-Nb, Fe-B, Fe-C alloy used in industry are divided into Fe 70.89 Ni 1.37 Cu 1.34 Nb 3.1 B 18.77 C 2.75 Si 1.01 mn 0.77 , (atomic percentage, at%) for raw material configuration, after the prepared metal raw material is melted and refined in a vacuum induction furnace, the molten metal liquid is poured into an insulated crucible, and enters a draft tube and a nozzle, at this time the melt The stream is atomized by the high pressure gas stream. The atomized metal powder solidifies and settles in the atomizing tower, and falls into the powder collecting tank;

[0031] (2) 35CrMo steel is selected as the base material, and the oxide removal and surface cleaning are carried out on the surface of the base material in sequence before plasma surfacing. Among them, the oxide removal adopts the grinding method until the metallic luster is exposed; the...

Embodiment 2

[0036] Step (1), step (2) and step (4) are all identical with embodiment 1, only adjust the process parameter of plasma overlay welding in step (3) as follows: welding voltage 28V, welding current 150A, welding speed 35mm / min, The protective airflow speed is 12L / min, the powder feeding speed is 25g / min, and the swing range is 26mm.

[0037] Performance evaluation:

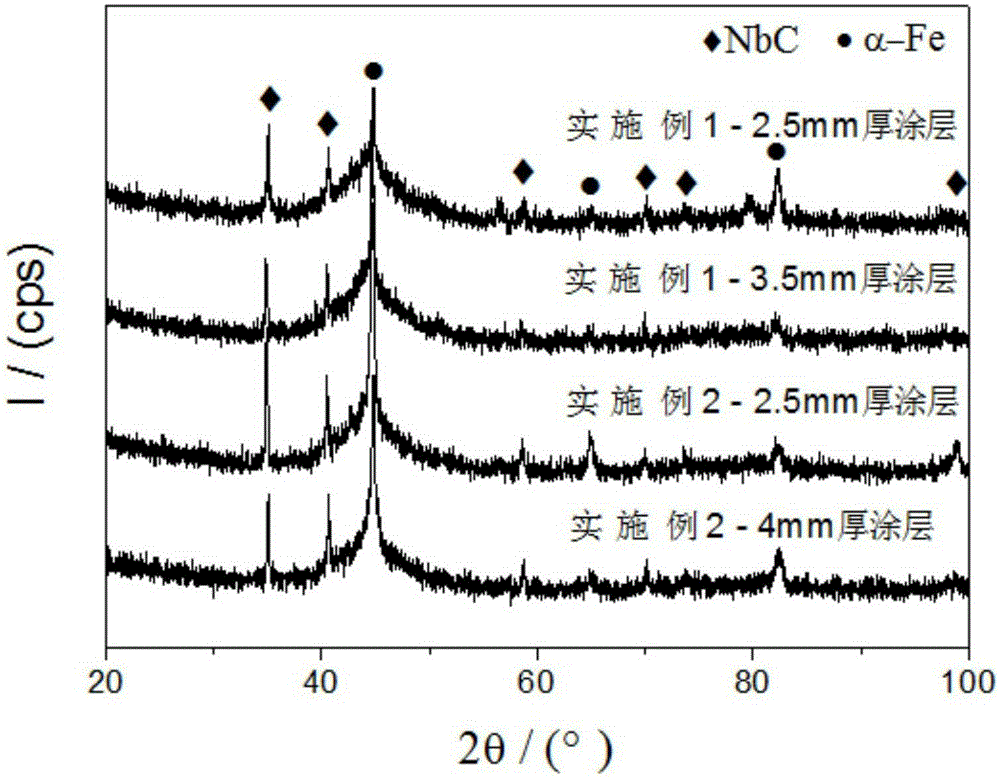

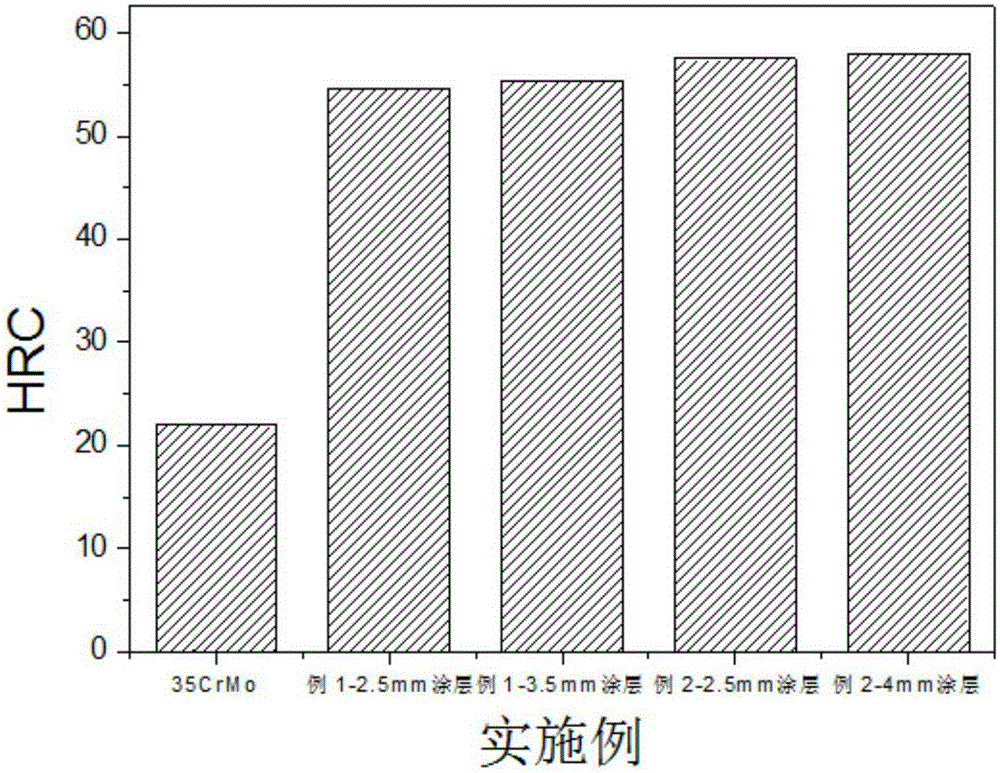

[0038] The following iron-based amorphous nanocrystalline composite coatings prepared in Example 1 and Example 2 are evaluated by microstructure test and observation, crack resistance test, hardness test and wear resistance test respectively:

[0039] (1) The iron-based amorphous nanocrystalline composite coatings prepared in Example 1 and Example 2 can be seen from the macroscopic appearance, the coating is well formed, and the coating has no cracks; and after the coloring penetrant inspection, it is found that the coating has no cracks , indicating that the coating has good crack resistance.

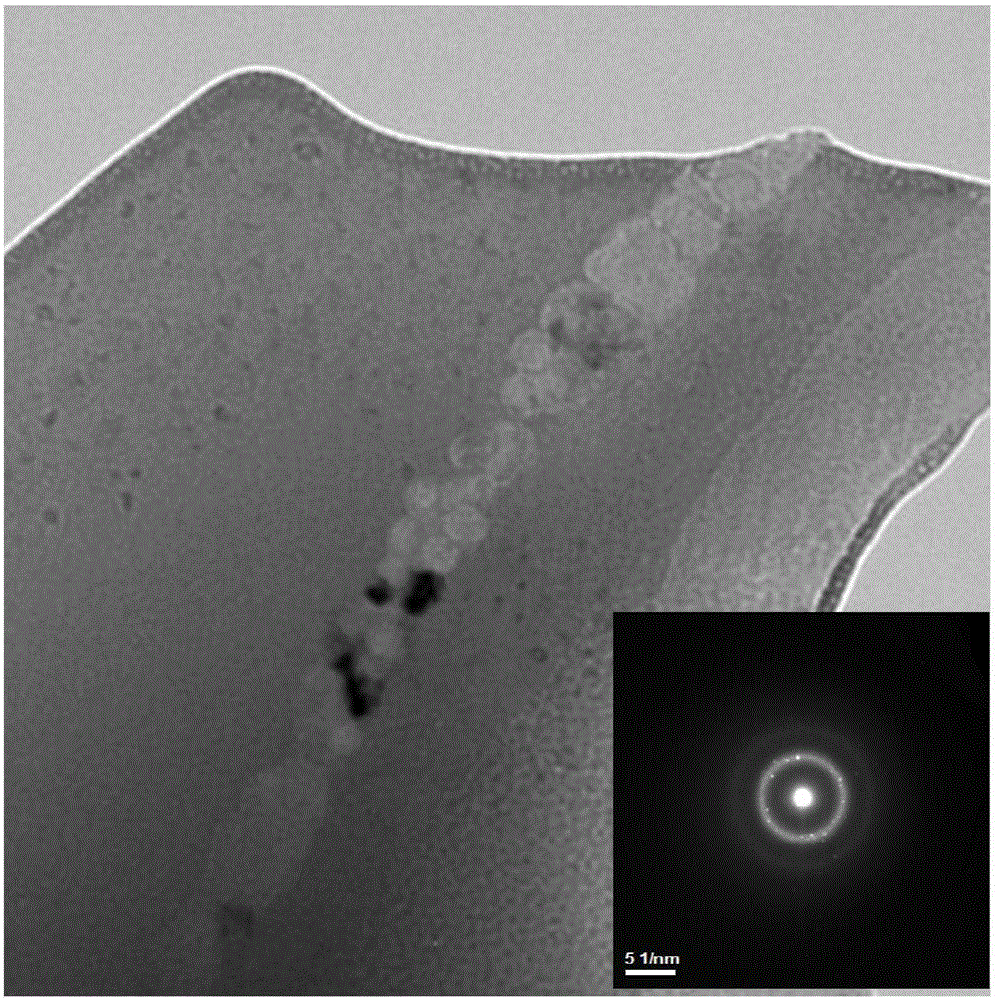

[0040](2) In orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com