Powder for laser cladding, preparation method and application thereof

A laser cladding and powder technology, applied in transportation and packaging, metal processing equipment, coatings, etc., can solve the problems of insufficient surface hardness, strength and wear resistance of workpieces, and achieve improved adhesion, performance and wear resistance. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of powder for laser cladding, quality is 30kg, comprises metal powder and graphite powder, and described graphite powder is attached to the surface of described metal powder; In the mass meter of powder for laser cladding, described metal powder and described graphite The mass ratio of powder is 100:0.3.

[0058] The metal powder is selected from 316L stainless steel powder, which requires no hollow powder and a particle size of 65-200 μm. The graphite powder is high-purity graphite powder with a purity ≥ 99.9 wt%, a particle size of 1-50 μm, and a Mohs hardness of 1-2. Use the electron microscope to observe the adhesion effect of the powder for laser cladding, see the attached electron microscope picture figure 1 .

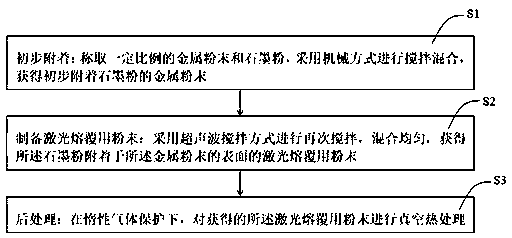

[0059] The preparation method of the above-mentioned powder for laser cladding comprises the following steps:

[0060] S1. Preliminary attachment: Weigh a certain proportion of metal powder and graphite powder, and stir and mix them mechanically ...

Embodiment 2

[0066] A kind of powder for laser cladding, quality is 30kg, comprises metal powder and graphite powder, and described graphite powder is attached to the surface of described metal powder; In the mass meter of powder for laser cladding, described metal powder and described graphite The mass ratio of powder is 100:0.3.

[0067] The metal powder is selected from 17-4PH stainless steel powder, which requires no hollow powder and a particle size of 65-200 μm. The graphite powder is high-purity graphite powder with a purity ≥ 99.9 wt%, a particle size of 1-50 μm, and a Mohs hardness of 1-2.

[0068] The preparation method of the above-mentioned powder for laser cladding comprises the following steps:

[0069] S1. Preliminary attachment: Weigh a certain proportion of metal powder and graphite powder, and stir and mix them mechanically to obtain metal powder with graphite powder initially attached.

[0070] S2. Preparation of powder for laser cladding: use an ultrasonic stirrer to ...

Embodiment 3

[0075] A kind of powder for laser cladding, quality is 30kg, comprises metal powder and graphite powder, and described graphite powder is attached to the surface of described metal powder; In the mass meter of powder for laser cladding, described metal powder and described graphite The mass ratio of powder is 100:1.

[0076] The metal powder is selected from 0Cr18Ni9 stainless steel powder, which requires no hollow powder and a particle size of 65-200 μm. The graphite powder is high-purity graphite powder with a purity ≥ 99.9 wt%, a particle size of 1-50 μm, and a Mohs hardness of 1-2.

[0077] The preparation method of the above-mentioned powder for laser cladding comprises the following steps:

[0078] S1. Preliminary attachment: Weigh a certain proportion of metal powder and graphite powder, and stir and mix them mechanically to obtain metal powder with graphite powder initially attached.

[0079] S2. Prepare powder for laser cladding: use an ultrasonic stirrer to stir ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com