Reinforced and antifriction ultra-high molecular weight polyethylene composite material

An ultra-high molecular weight, composite material technology, applied in the field of ultra-high molecular weight polyethylene composite material and its preparation, can solve the problems of difficult mass production, difficult solvent recovery, complicated equipment, etc., and achieves easy industrial production and less solvent usage. , The effect of simple production equipment

Active Publication Date: 2010-11-10

SHANGHAI RES INST OF CHEM IND +1

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The grafting rate of the solution grafting method is high, but it is difficult to recover the solvent, and it is not easy to carry out large-scale production; in addition, the use of radiation and plasma requires complex equipment and relatively large investment

Method used

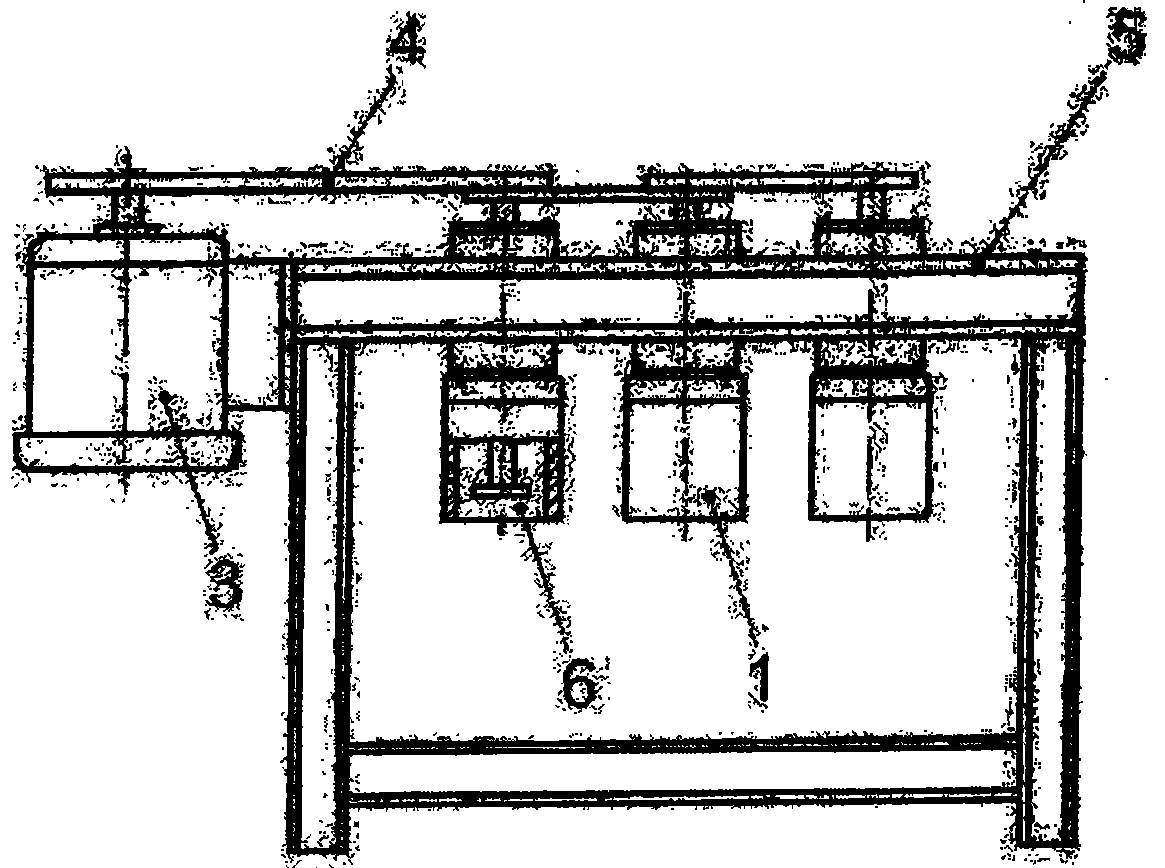

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

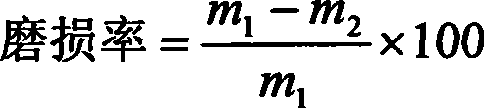

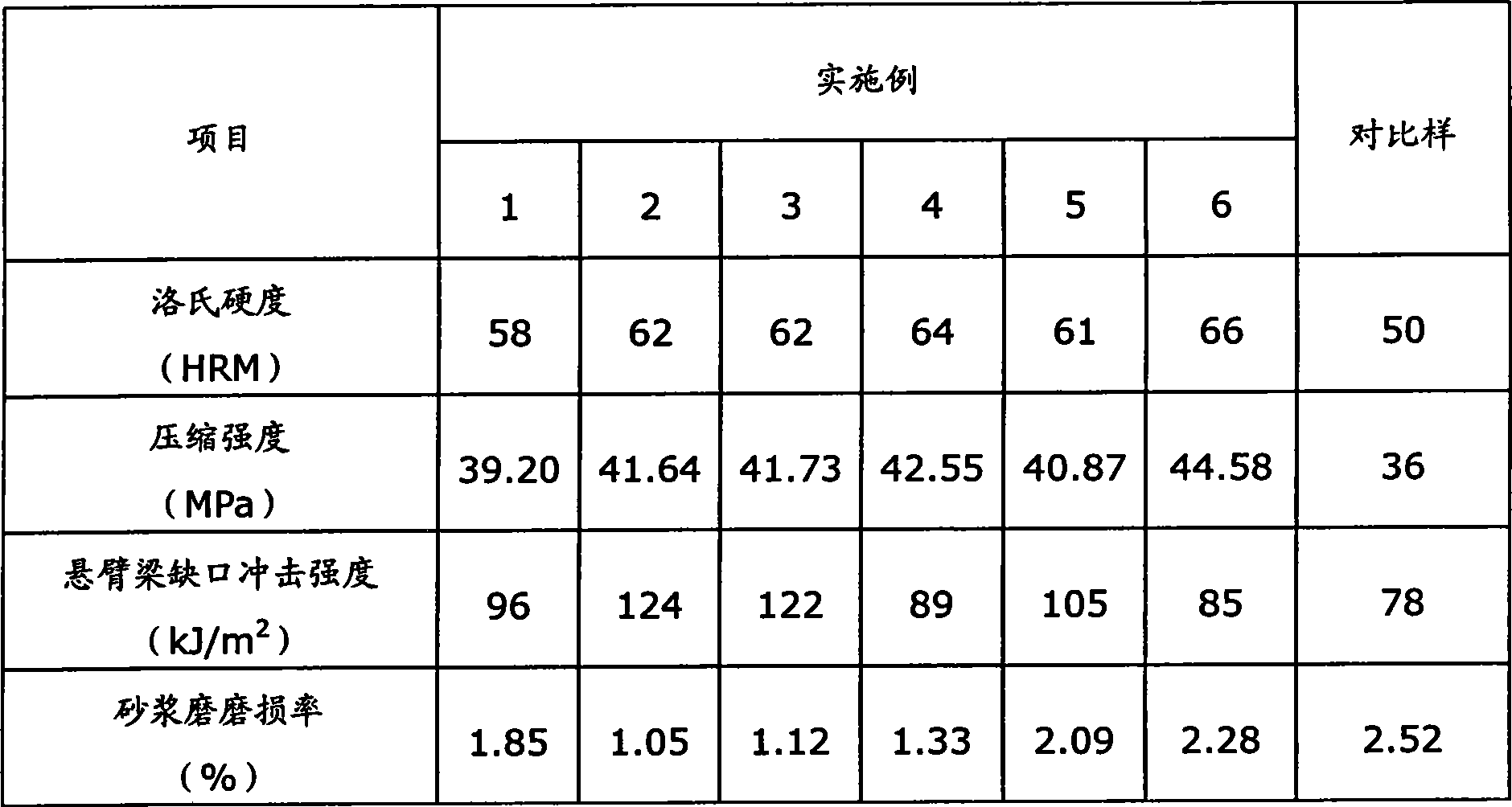

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a strength reinforced and antifriction ultrahigh molecular weight polyethylene composite material. The composite material comprises ultrahigh molecular weight polyethylene and superfine inorganic powder. The composite material adopts the coupling agent processed superfine inorganic powder for filling, and is prepared through solid phase grafting technology, thereby obviously improving the compatibility of components and functionally modifying the surface of the composite material. The solid phase grafting technology has little solvent consumption, simple production equipment, convenience for the industrialized production, and good development prospect.

Description

A reinforced anti-friction ultra-high molecular weight polyethylene composite material technical field The invention relates to the polymer composite material industry in the field of chemical industry, in particular to an ultra-high molecular weight polyethylene composite material and a preparation method thereof. Background technique Ultra-high molecular weight polyethylene (hereinafter referred to as UHMWPE) is a polyethylene with a viscosity average molecular weight of more than 1.5 million. It is a type of polyethylene with incomparable wear resistance, impact resistance and low temperature resistance, etc. Engineering thermoplastics with excellent properties. But it also has its own inherent defects, such as low heat distortion temperature, poor surface hardness, poor abrasive wear and fatigue wear resistance, large dimensional shrinkage, etc. In many aspects, it cannot meet the actual needs of customers. Therefore, it is necessary to use new technology to modify UH...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F255/02C08F2/44C08K9/04

Inventor 张玉梅徐静安吴向阳张炜夏晋程洪尉赵春保

Owner SHANGHAI RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com