Bright red nanometer glaze slip for ceramic sanitary wares as well as preparation method and application of bright red nanometer glaze slip

A technology of sanitary ceramics and bright red, applied in the field of sanitary ceramics, can solve the problems of pure ceramic materials such as wear resistance, stain resistance, service life, environmental protection gap, color impurity, etc., and achieve stable and pure color development and uniform glaze color , bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

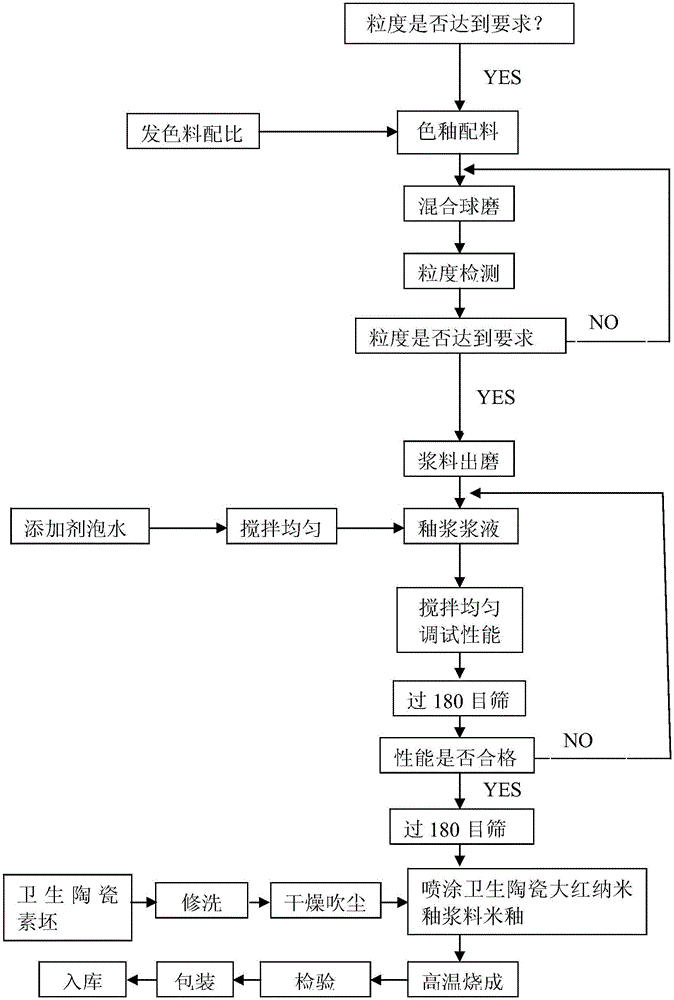

[0036] Such as figure 1 shown, including the following steps:

[0037] (1) Preparation of sanitary ceramic green body: including:

[0038] a. Weigh the raw material components according to the component weight percentage of the green body: SiO 2 60-65%, Al 2 o 3 20~23%, CaO0~1%, MgO0~0.8%, K 2 O2~4%, Na 2 O0.1~0.5%, Fe 2 o 3 +TiO 2 1-2%, the remaining auxiliary raw materials 1-2.5%, the remaining auxiliary raw materials include alkali flour, water glass, dolomite; Auxiliary raw materials are mixed, adding appropriate amount of water and finely crushed by ball milling. When the particle size reaches 10μm, accounting for 67-72%, the slurry is discharged from the mill, and then iron is removed, sieved, refined and stale to make slurry (concentration: 350±2g / 200mL , slurry temperature is 30±5℃, viscosity V 0 60±5s / 100mL, viscosity V 30 is 110±5s / 100mL, yield value is 15±4);

[0039] b. Grouting the above mud in a gypsum model, drying the slurry at a temperature of 25 t...

Embodiment 2

[0047] According to the technical scheme of embodiment 1, select kaolin, washed china clay, washed ball clay, potassium feldspar, hard kaolin, pyrophyllite, etc. in corresponding proportions by the chemical composition of the formula in table 1 to carry out batching; add an appropriate amount of water through ball milling When the particle size reaches 10μm, accounting for 67% to 70%, the slurry is released and milled. After iron removal, sieving, refining, and aging, the slurry with excellent performance is made, and then grouted in the plaster model. After pulping, consolidation and demoulding, dry in a drying room at a temperature of (25-55)°C and a humidity of (5-75)% until the moisture content is below 5%, and the sanitary ceramic green body is obtained.

[0048] Table 1 Green Body Formula Chemical Composition List (weight percent, %)

[0049] components

SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

K 2 o

CaO

Na 2 o

MgO

Burn ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com