Isolating switch with quick break function

A technology for isolating switches and conductive parts, which is applied in the field of switches and can solve problems such as rising product costs, inappropriate installation, and easy-to-ablate contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

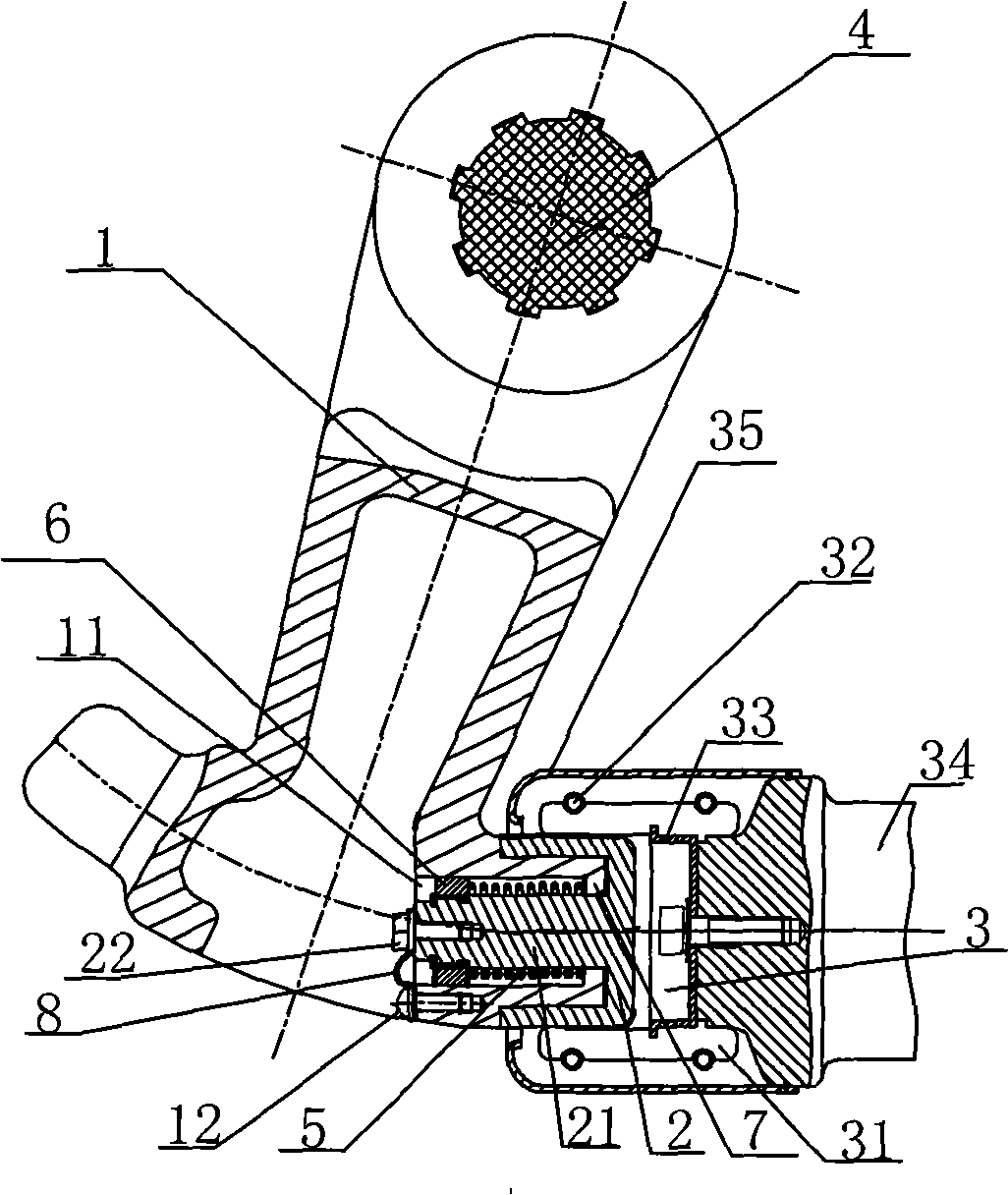

[0020] Such as figure 1 As shown, an isolating switch with a quick split function includes a moving contact 1, a quick split moving contact 2, a static contact 3, and an insulating rotating shaft 4 that controls the movement of the moving contact 1. The static contact 3 includes a static contact base 35, a cage 33, a static contact finger 31 and a tension spring 32. The static contact finger 31 is connected to the static contact base 34, and the static contact finger 31 is surrounded by a tension spring. 32. A shield 35 is provided on the outer surface of the static contact 3.

[0021] The fast moving contact 2 is a cup body with an axial column 21, and the closed end of the cup body is inserted into the static contact 3. The other end of the quick transfer contact 2 is sleeved with the front end of the moving contact 1. The front end of the moving contact 1 is provided with a cylindrical cavity 11, and the front end of the cylindrical cavity 11 is provided with a retaining ring ...

Embodiment 2

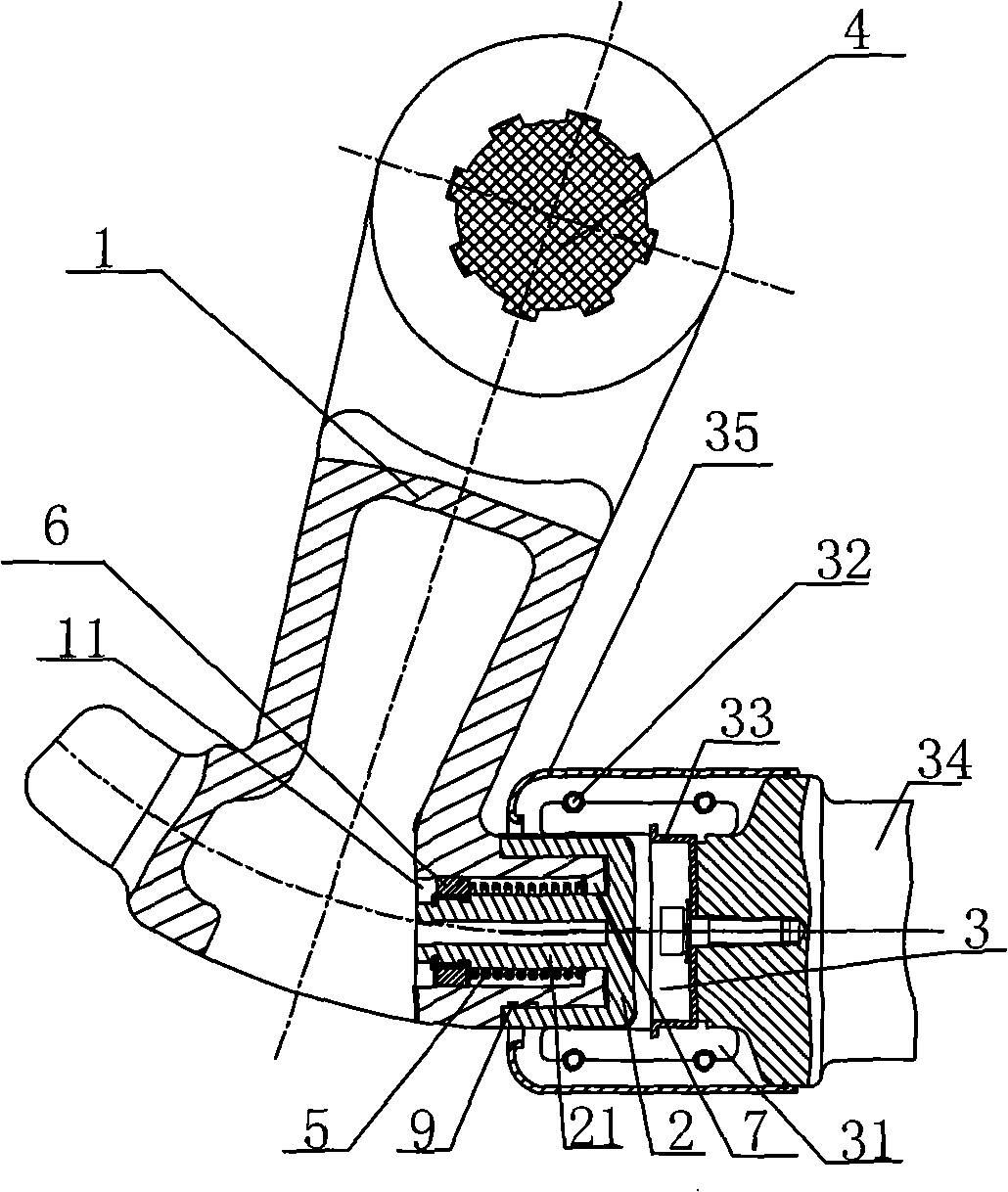

[0024] Such as figure 2 As shown, an isolating switch with a quick split function includes a moving contact 1, a quick split moving contact 2, a static contact 3, and an insulating rotating shaft 4 that controls the movement of the moving contact 1. The static contact 3 includes a static contact seat 34, a holder 33, a static contact finger 31, and a tension spring 32. The static contact finger 31 is connected to the static contact seat 34, and a tension spring surrounds the circumference of the static contact finger 31 32. A shield 35 is provided on the outer surface of the static contact 3.

[0025] The fast moving contact 2 is a cup body with an axial column 21, and the closed end of the cup body is inserted into the static contact 3. The other end of the quick transfer contact 2 is sleeved with the front end of the moving contact 1. The front end of the moving contact 1 is provided with a cavity 11, and the front end of the cylindrical cavity 11 is provided with a retaining ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com