Silane coupling agent containing vinyl ether chain segment, and preparation method and application thereof

A technology of silane coupling agent and polyoxyethylene ether, which can be used in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve the problems of restricting coupling agents and limited processing conditions, so as to improve comprehensive performance and improve dispersibility. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

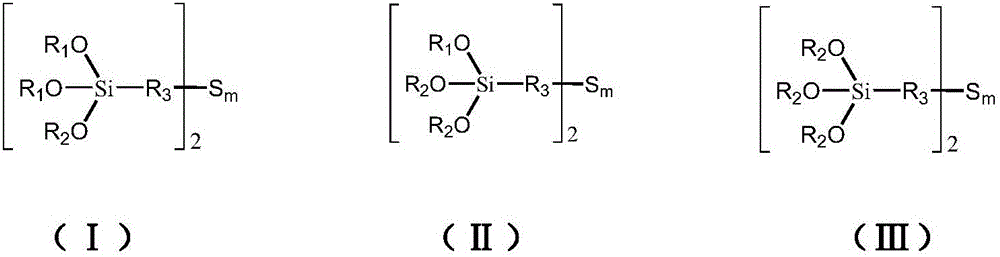

Method used

Image

Examples

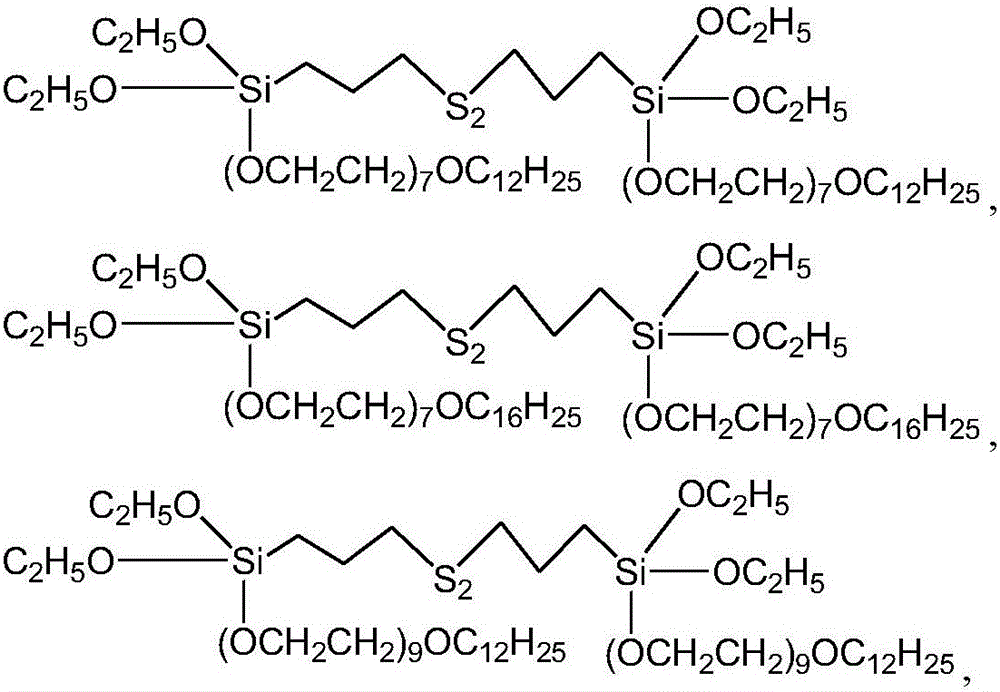

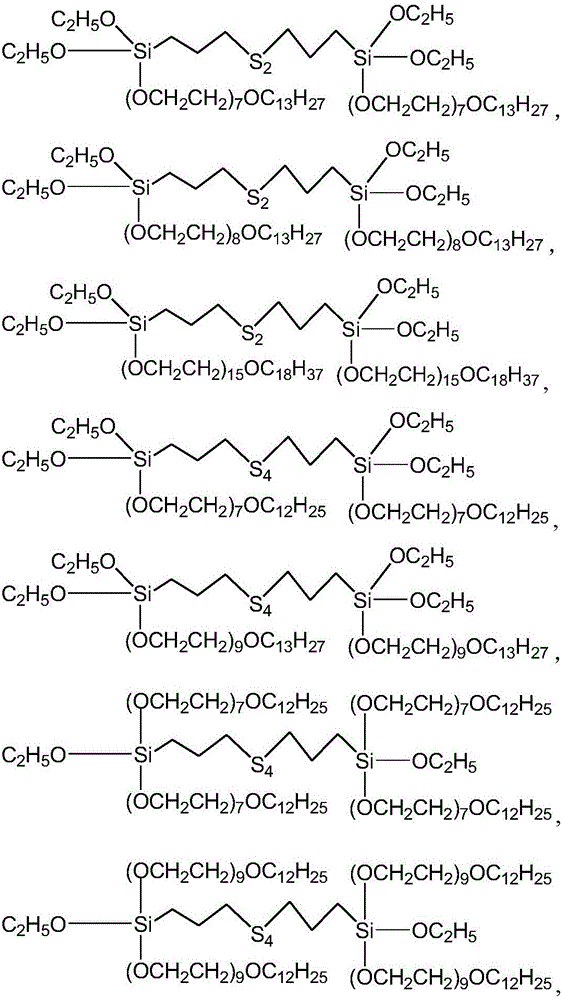

Embodiment 1

[0048] 26.95g bis-(γ-triethoxysilylpropyl) tetrasulfide, i.e. Si69 and 49.5g fatty alcohol polyoxyethylene ether primary alcohol AEO-7, the structural formula is Commercial product produced by BASF Corporation. Among them, R 4It is a straight chain aliphatic hydrocarbon chain, C=12-16, EO number k=7, put it into a 200ml three-necked flask equipped with a stirring device and a distillation device, the molar ratio of the feeding material is 1:2, and add 0.230g tetrabutyl titanate Catalyst, stirred and reacted at a temperature of 100°C for 3 hours, the reaction was carried out under the protection of nitrogen, and the ethanol generated during the reaction was continuously distilled out of the system. The mixture was rotary evaporated at 80°C and 50mpa in the later stage to obtain a yellow liquid satisfying the formula (I), wherein R 1 is ethyl, R 2 for R 3 for -CH 2 CH 2 CH 2 -.

Embodiment 2

[0050] 26.95g bis-(γ-triethoxysilylpropyl) tetrasulfide, i.e. Si69 and 49.5g fatty alcohol polyoxyethylene ether primary alcohol AEO-7, the structural formula is Among them, R 4 It is a straight-chain aliphatic hydrocarbon chain, C=12-16, EO number k=7, put it into a 200ml three-necked flask equipped with a stirring device and a distillation device, the molar ratio of the feed is 1:2, and add 0.230g of p-benzenemethanesulfonic acid Catalyst, stirred and reacted at a temperature of 120°C for 2.5 hours, and the reaction was carried out under the protection of nitrogen, and the ethanol generated during the reaction was continuously distilled out of the system. The mixture was rotary evaporated at 80°C and 50mpa in the later stage to obtain a yellow liquid satisfying the formula (I), wherein R 1 is ethyl, R 2 for R 3 for -CH 2 CH 2 CH 2 -.

Embodiment 3

[0052] 40.43g bis-(γ-triethoxysilylpropyl) tetrasulfide, i.e. Si69 and 148.5g fatty alcohol polyoxyethylene ether primary alcohol AEO-7, the structural formula is Among them, R 4 It is a straight-chain aliphatic hydrocarbon chain, C=12-16, EO number k=7, put it into a 500ml three-necked flask equipped with a stirring device and a distillation device, the molar ratio of the feed is 1:4, and add 0.510g of p-benzenemethanesulfonic acid Catalyst, stirred and reacted at a temperature of 120°C for 3 hours, and the reaction was carried out under the protection of nitrogen, and the ethanol generated during the reaction was continuously distilled out of the system. The mixture is rotary evaporated at 80°C and 50mpa in the later stage to obtain a yellow liquid satisfying the formula (II), wherein R 1 is ethyl, R 2 for R 3 for -CH 2 CH 2 CH 2 -.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com