Leakage protection plug

A leakage protection plug, all-round technology, applied in emergency protection circuit devices, emergency protection devices with automatic disconnection, circuits, etc., can solve problems such as shell live, electric shock accidents, etc., to ensure personal safety, user safety, and prevent theft. The effect of the national electricity situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

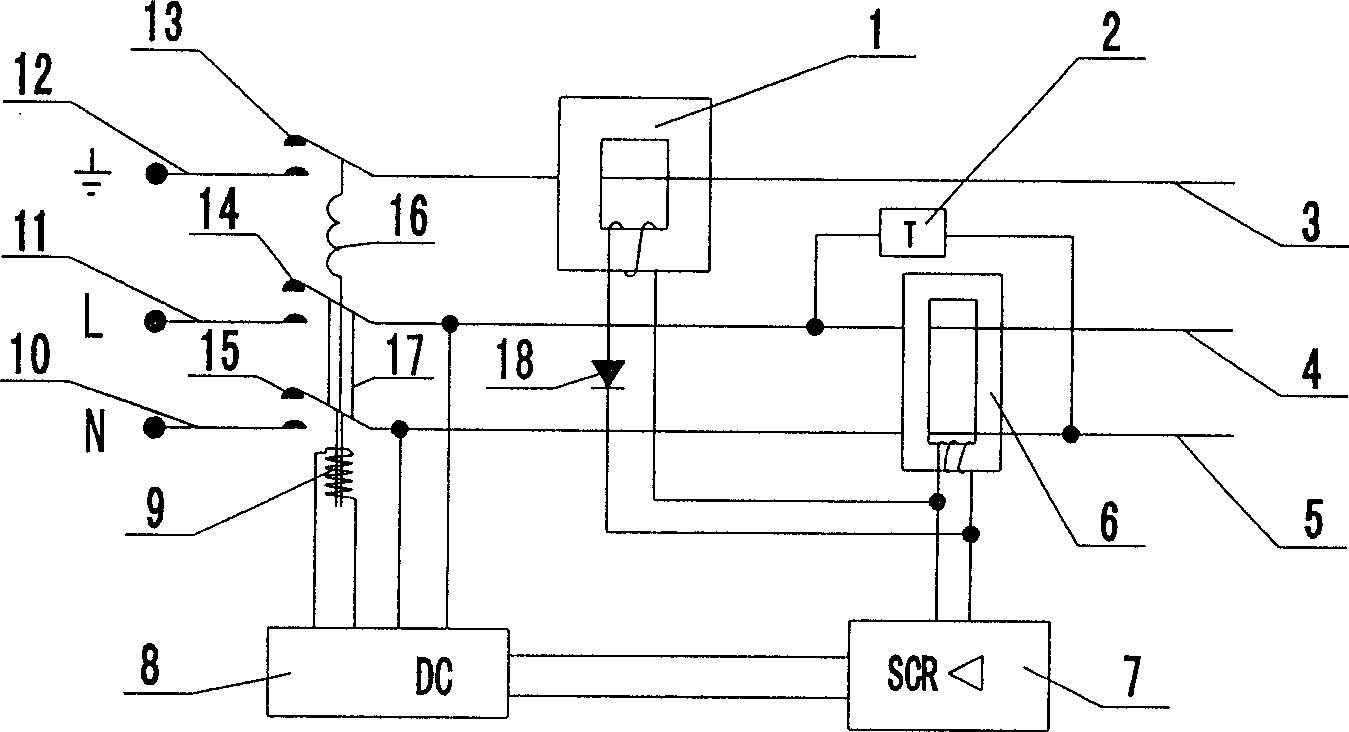

[0016] see figure 1 As shown, an embodiment of the present invention, the all-round leakage protection plug is composed of a zero-sequence current transformer 6, a ground wire electrification detection sensor 1, an amplifier circuit 7, a test circuit 2, a free release device 9, a breaker 17, and a grounding sequence device , High temperature resistant, flame retardant internal connecting wires 10, 11, 12, DC power supply 8, and power cords 3, 4, 5. The grounding sequence device is composed of a pair of ground wire contacts 13, a breaker 17, and a spring 16. The two ends of the spring 16 are respectively connected with the upper end of the push-pull rod of the breaker 17 and the copper reed of the ground wire moving contact 13, so that the ground wire The moving and static contacts of the moving contact 13 always have a spring force that attracts each other. In this way, when the free release 9 drives the breaker 17 to move up or down, the phase line contact 14 and the neutral ...

Embodiment 2

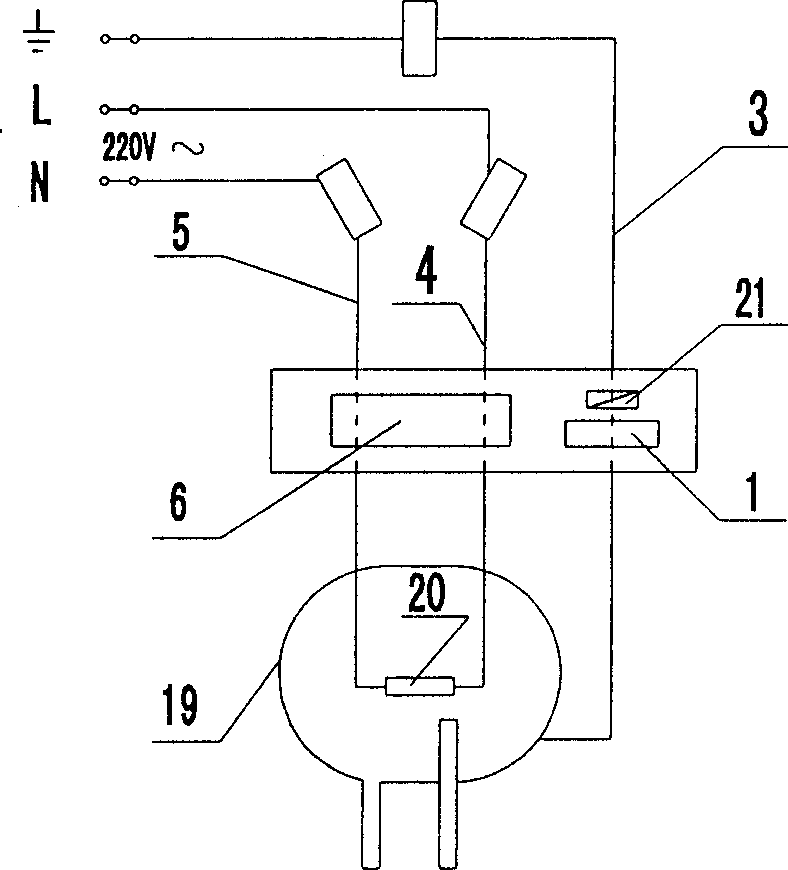

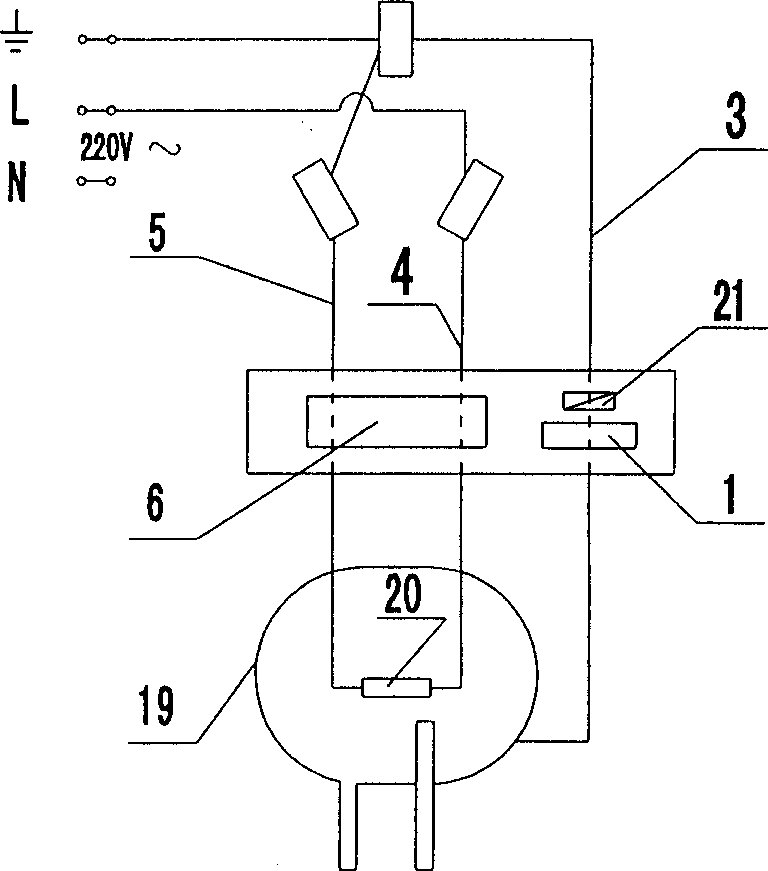

[0018] see figure 2 , image 3 Shown, the present invention is applied to an embodiment on the electric water heater. The phase and neutral wires 4 and 5 of the power line are connected to the load 20 of the water heater 19, and the ground wire 3 is connected to the shell. The phase and zero wires 4 and 5 of the power line pass through the zero-sequence current line sensor 6 and are connected to the phase and zero pole copper pins of the plug, and the ground wire passes through the inductor 1 and is connected to the ground pole copper pin through the grounding sequence device. When the water heater load 20 leaks electricity, there is a residual current between the phase and neutral wires 4 and 5, or when the local wire 3 has a current due to unexpected reasons, the zero-sequence current transformer 6 or the secondary of the inductor 1 will generate a signal. When the residual current or leakage current is greater than a specified value (such as 10mA or 50mA), the three pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com