Ceramic atomization element and smoke cartridge

一种雾化芯、陶瓷的技术,应用在烟草、吸烟者用品、包装等方向,能够解决雾化芯组装难度大、导液绳储液能力差、接触烟液面积小等问题,达到物理特性稳定、导液速度快、烟液面积大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

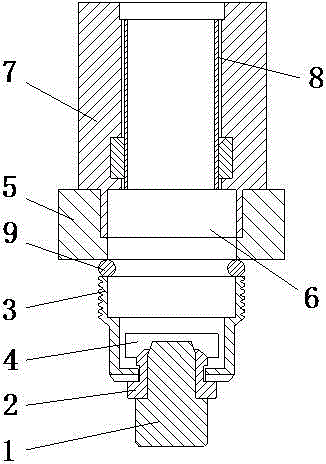

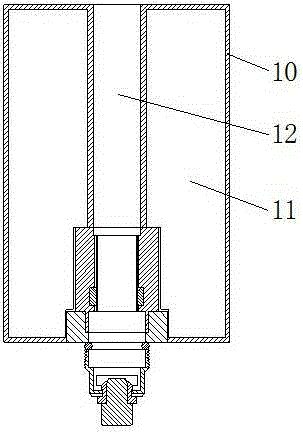

[0020] A ceramic atomizing core provided by the present invention, such as figure 1 As shown, it includes a power supply positive terminal 3, a power supply negative terminal 1, and a fixing seat 5. An air inlet 4 is provided on the outer wall of the power supply positive terminal 3 facing the inner wall, and the power supply negative terminal 1 is installed on the The lower end of the positive terminal 3 of the power supply, and an insulating ring 2 is installed between the inner wall of the positive terminal 3 of the power supply and the outer wall of the negative terminal 1 of the power supply, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com