Electroplating solution, preparation method thereof and galvanization technique utilizing electroplating solution

A technology of electroplating solution and solution, applied in the field of galvanizing process, can solve the problems that cannot be widely used, current efficiency, equalizing ability and deep plating ability cannot be compared, and achieves improvement of deep plating ability and improved uniform plating ability. , the effect of improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

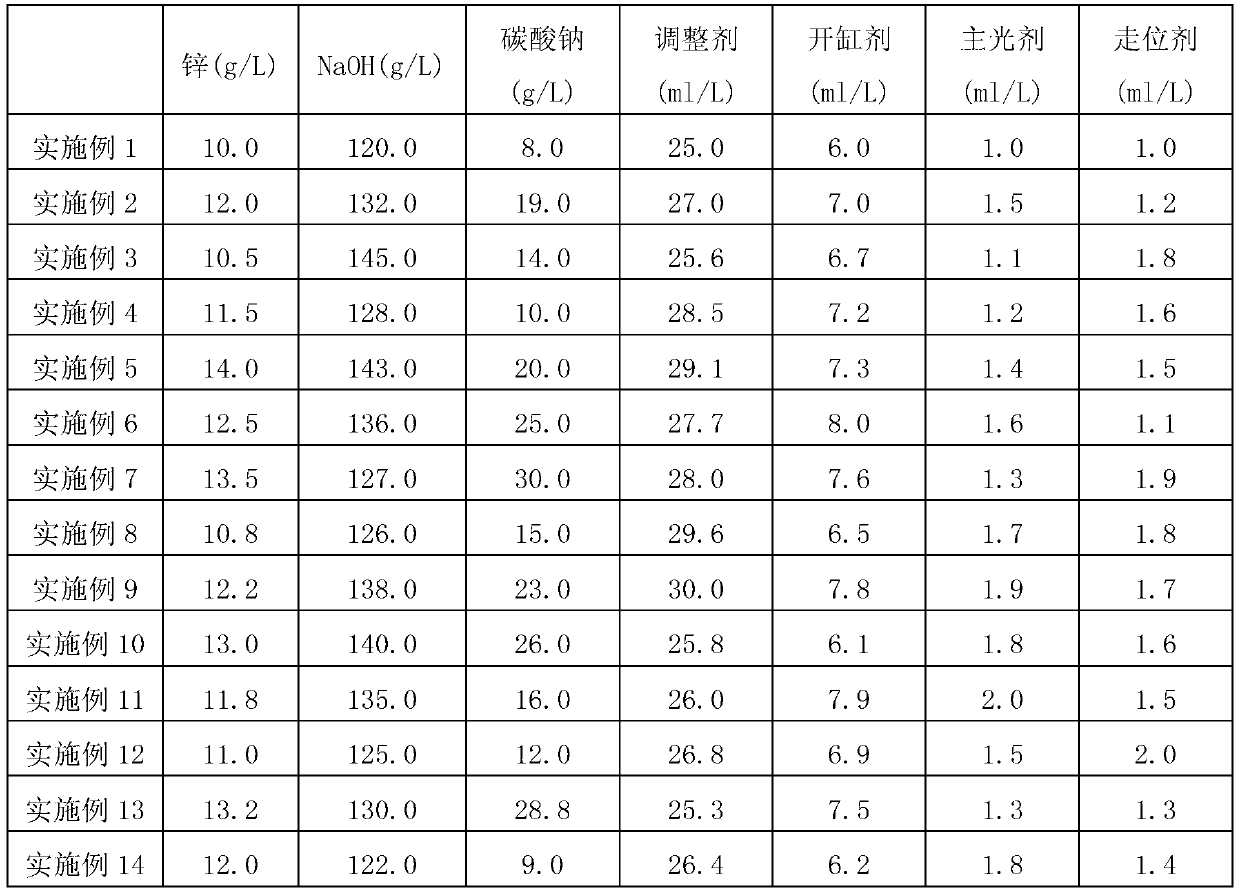

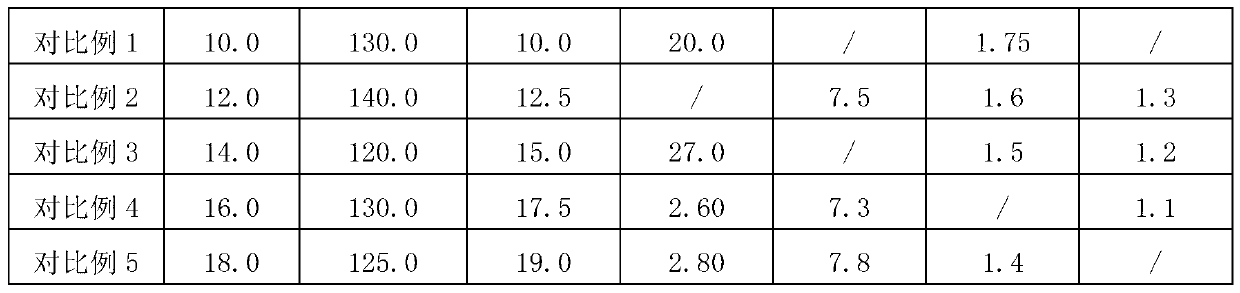

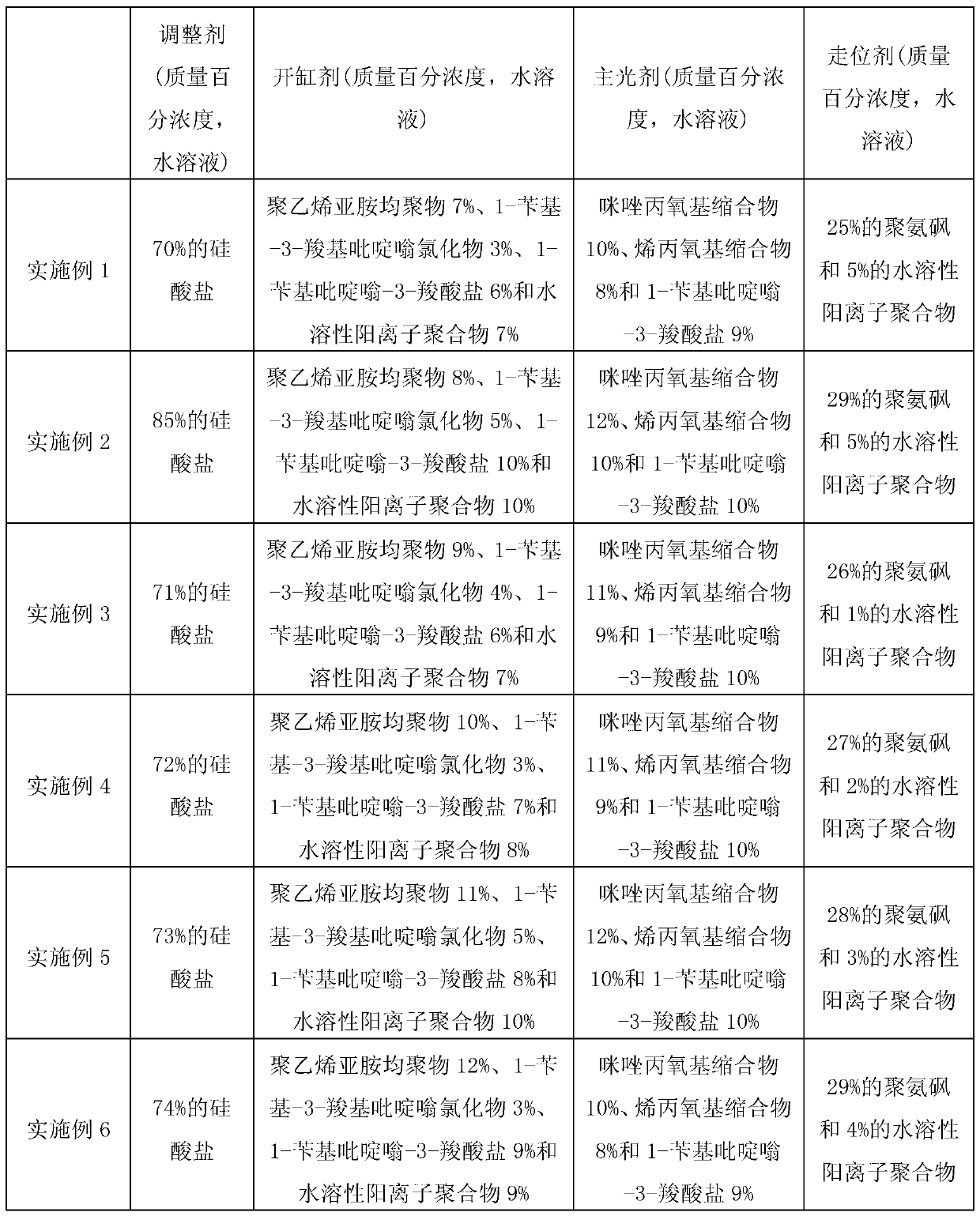

[0027] The present invention will be described in further detail below by way of examples.

[0028] Thoroughly clean the electroplating tank, zinc dissolving tank and filter element. The electroplating bath may be an electroplating bath made of polypropylene or polyvinyl chloride resin material. If the electroplating tank and zinc dissolving tank are old tanks, they need to be thoroughly cleaned before use. If they are new tanks, they need to be soaked in 10% warm sodium hydroxide solution before use.

[0029] First of all, it is equipped with a zinc melting tank. Add 2 / 3 of pure water to the zinc dissolving tank, add sodium carbonate to the concentration in Table 1, and slowly add NaOH under stirring. At this time, temporarily add an air duct to help dissolve and prevent NaOH from accumulating at the bottom of the tank and agglomerating. At this time, the solution will release heat, and the temperature of the solution needs to be monitored, and the temperature should not ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com