Activated carbon regeneration device and method

A regeneration device and activated carbon technology, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of reduced mechanical strength of regenerated carbon, changes in the chemical structure of carbon surface, and loss of activated carbon by oxidation and combustion, and achieve good regeneration quality , Low regeneration cost, not easy to burn out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

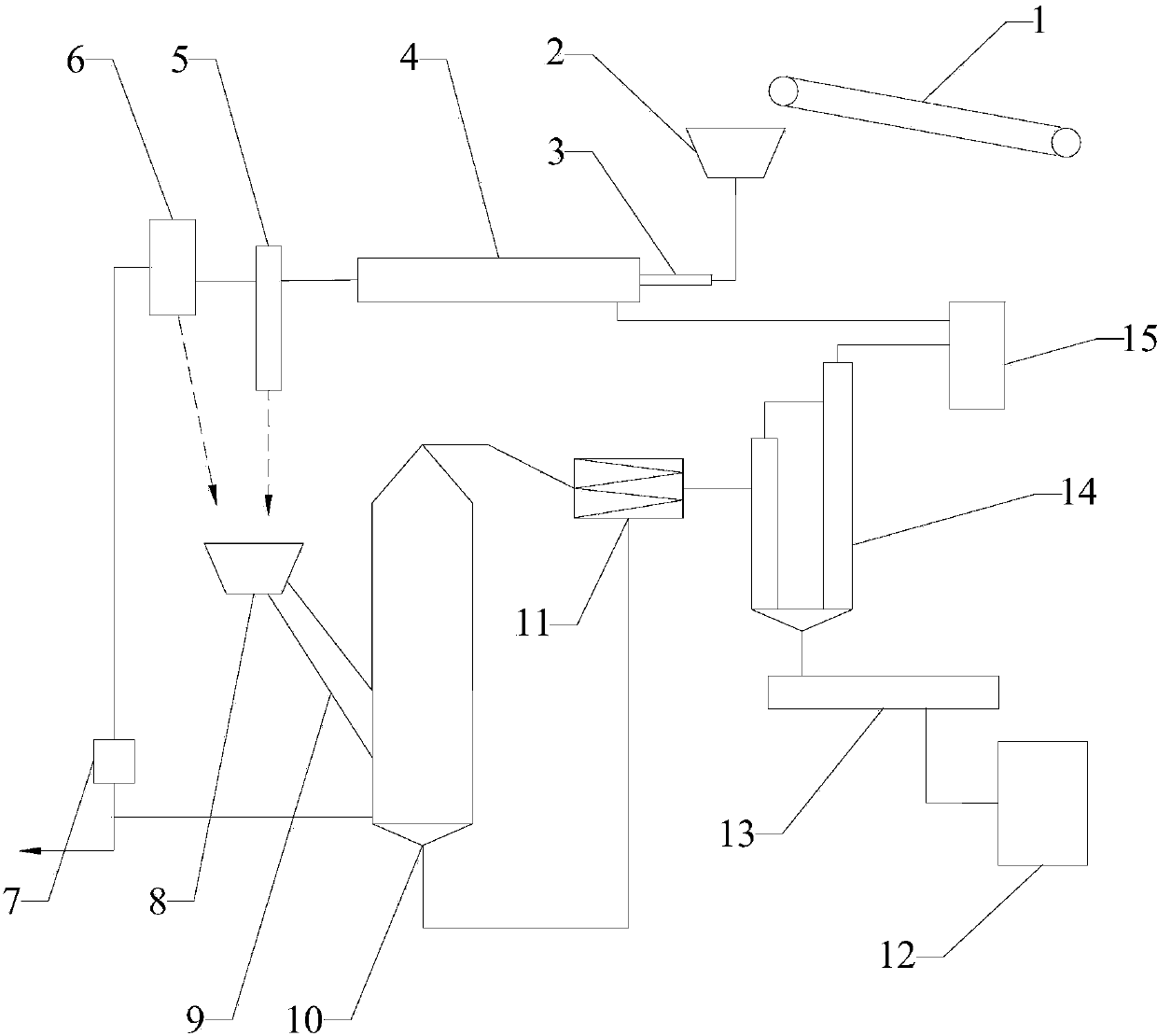

[0037]The activated carbon regeneration device of the present invention includes a feeding system, a drying and collecting carbon material system, an activation system, and an activation material collection and furnace gas circulation system. Specifically, the wet waste powder charcoal is sent from the belt conveyor 1 to the first hopper 2, and then fed to the drying converter 4 through the first electric vibration feeder 3. After the dry matter comes out of the furnace, it enters the cyclone separator 5 and the dust collector 6, and the dry charcoal powder falls into the second hopper 8, and is sent to the boiling activation furnace 10 by the second electric vibrating feeder 9; the converter gas after passing the dust collector is used High-pressure blower 7, or emptying as required, or return to boiling activation furnace 10 uses. Dry charcoal powder is activated in the high-temperature boiling activation furnace 10 with superheated steam sprayed from the bottom of the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com