Nonstick coating with high heat conductivity and high wear resistance

A non-stick coating, high thermal conductivity technology, applied in the direction of coating, can solve the problems of poor heat distribution of non-stick pan, cracked coating film, reduced coating service life, etc., achieve excellent mechanical strength, high thermal conductivity, VOC emission low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of SPEEK

[0025] Mix 10g of PEEK and 10g of chlorosulfonic acid evenly, raise the temperature to 120°C, react for 72h, pour into 100g of cold water at 5°C and let it stand for 1h, wash with distilled water until the pH of the lotion is 6-7, and dry it in a vacuum oven for 50 ℃ to obtain SPEEK after vacuum drying.

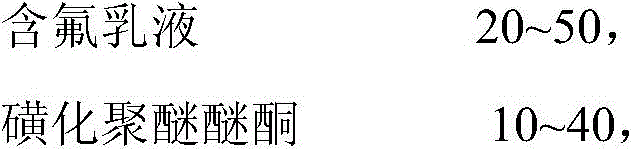

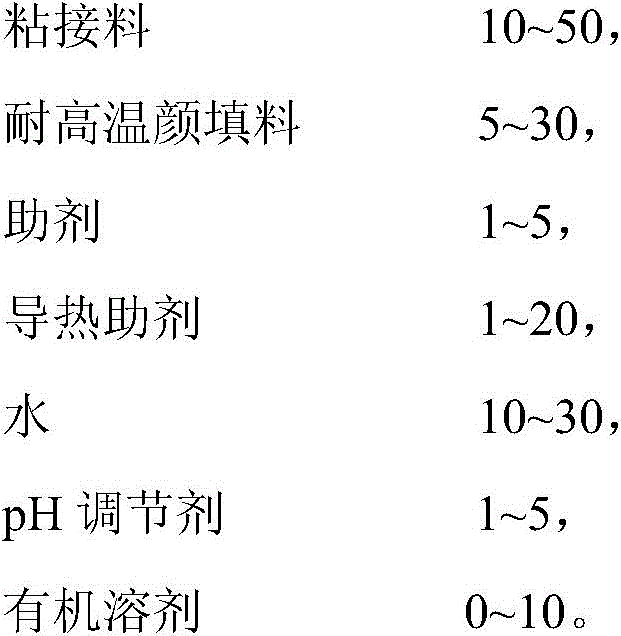

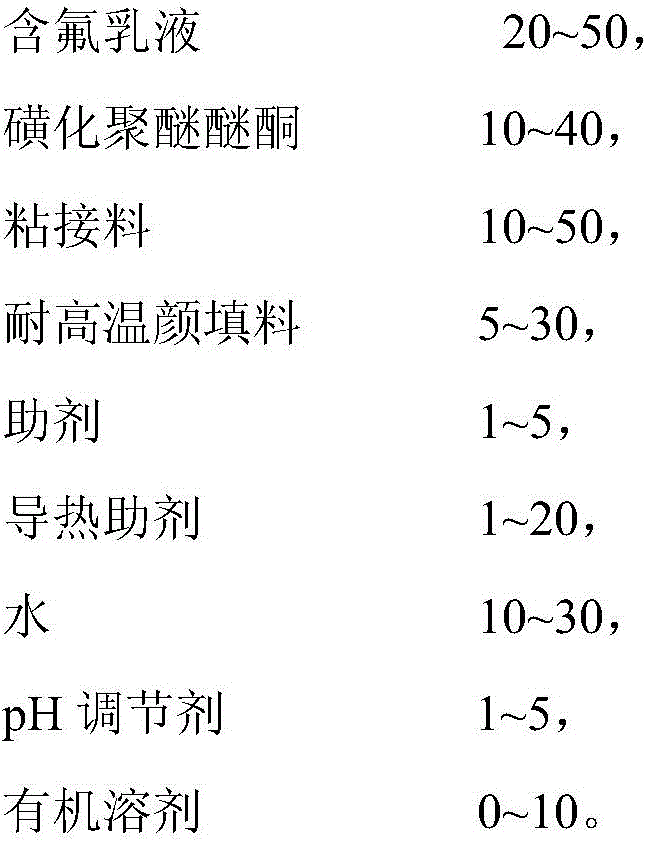

[0026] (2) Preparation of non-stick coating

[0027] Mix 5g of silicon carbide, 5g of carbon black, 1g of dispersant, 0.5g of defoamer, 1g of graphene, 11g of deionized water, and 1g of NMP, grind to the required particle size, and then add SPEEK10g and 40g of PTFE emulsion prepared in step 1) , PES resin 20g, thickener 0.5g, AMP-95 (pH regulator) 5g and stir evenly to obtain a kind of high thermal conductivity and high wear resistance non-stick coating 1.

Embodiment 2

[0029] (1) Preparation of SPEEK

[0030] Mix 10g of PEEK and 500g of industrial concentrated sulfuric acid evenly, raise the temperature to 30°C, react for 48h, pour into 5000g of cold water at 5°C and let it stand for 5h, wash with distilled water until the pH of the lotion is 6-7, and dry it in a vacuum oven at 60°C SPEEK was obtained after vacuum drying.

[0031] (2) Preparation of non-stick coating

[0032] Mix 8g of ceramic powder, 7g of carbon black, 1g of dispersant, 0.5g of defoamer, 3g of diamond powder, 11g of deionized water, and 5g of NEP, grind to the desired particle size, and then add SPEEK15g and FEVE emulsion prepared in step (1) 30g, PAI resin 15g, thickener 0.5g, triethylamine (pH regulator) 5g were stirred evenly to obtain a kind of high thermal conductivity and high wear resistance non-stick coating 2.

Embodiment 3

[0034] (1) Preparation of SPEEK

[0035] Mix 10g of PEEK and 200g of trimethylsilylsulfonyl chloride evenly, heat up to 80°C, react for 8 hours, pour into 1000g of cold water at 10°C and let stand for 48 hours, wash with distilled water until the pH of the lotion is 6-7, and place in a vacuum drying oven SPEEK was obtained after vacuum drying at 80°C.

[0036] (2) Preparation of non-stick coating

[0037] Mix 5g of silicon carbide, 1g of dispersant, 1g of defoamer, 10g of graphite, and 10g of deionized water, grind to the desired particle size, and then add SPEEK10g, 20g of PTFE emulsion, 20g of PFA emulsion, and FEVE emulsion prepared in step (1). 10 g, 10 g of PPS resin, 2 g of thickener, and 1 g of ammonia water (pH regulator) were stirred evenly to obtain a non-stick coating 3 with high thermal conductivity and high wear resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com