Novel method for preparing crylic acid modified resin for two-component waterborne polyurethane adhesive

A polyurethane adhesive, water-based two-component technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as reduced bonding performance, fluctuations in bonding performance, and damage to the ecological environment , to achieve the effects of suppressing the occurrence of defects, reducing construction difficulty and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

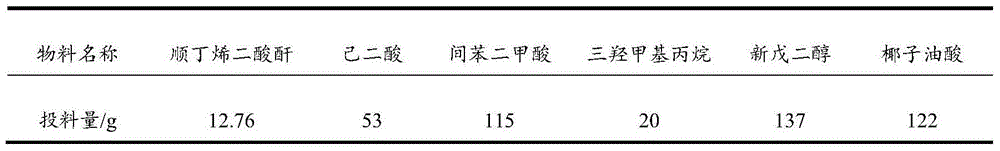

[0026] Table 1 Polyacid and polyalcohol feed list for partial synthesis of polyester

[0027]

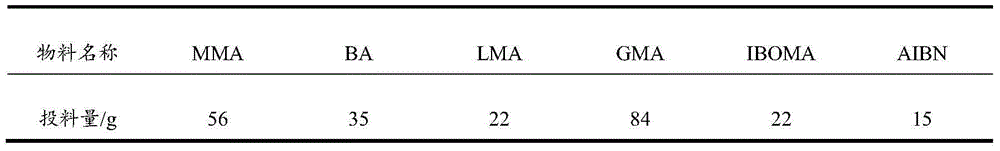

[0028] Table 2. Acrylic resin copolymer monomer initiator feed list

[0029]

[0030] a. Add the monomers in Table 1 except coconut oleic acid to the four-neck flask with stirring, thermometer and rectification column, control the temperature of the kettle not to exceed 230°C, the temperature of the column is 95-100°C, and react for 2-4hrs Weigh the amount of water, the acid value is less than 5mgKOH / g, add coconut oil acid, continue the reaction for 1-1.5hr, the acid value is less than 5mgKOH / g, and cool down to 100°C.

[0031] b. Add 150g propylene glycol methyl ether and 80g ethylene glycol monobutyl ether, and control the temperature to 90-100°C;

[0032] c. At 90-100°C, methyl methacrylate (MMA), butyl acrylate (BA), lauryl methacrylate (LMA), glycidyl methacrylate (GMA), isobornyl methacrylate Mix monomers such as ester (IBOMA) and azobisisobutyronitrile (AIBN) evenly,...

Embodiment 2

[0036] Table 3 Polyacid and polyol feed list for partial synthesis of polyester

[0037]

[0038] Table 4. Acrylic resin copolymer monomer initiator feed list

[0039]

[0040] a. Add the monomers in Table 1 except soybean oil to a four-neck flask equipped with stirring, thermometer and rectification column, control the temperature of the kettle not to exceed 230°C, and the temperature of the column at 95-100°C, and weigh after 2-4hrs of reaction The amount of water output, the measured acid value is less than 5mgKOH / g, add soy oil, continue the reaction for 1-1.5hr, the measured acid value is less than 5mgKOH / g, and cool down to 100°C.

[0041] b. At 100°C, methyl methacrylate (MMA), butyl acrylate (BA), butyl methacrylate (BMA), glycidyl methacrylate (GMA), isobornyl methacrylate ( IBOMA) and other monomers and benzoyl peroxide (BPO) were mixed evenly, and added dropwise into a four-necked bottle, and the dropwise addition time was 2-2.5hr. After the dropwise addition...

Embodiment 3

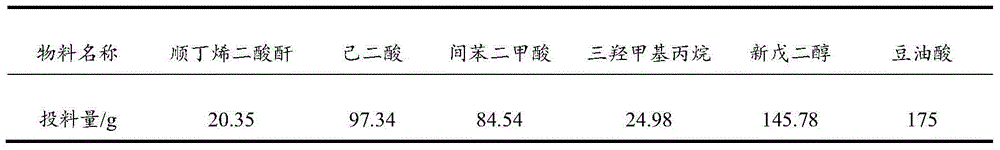

[0045] Table 5 Polyacid and polyol feed list for partial synthesis of polyester

[0046]

[0047] Table 6. Acrylic resin copolymer monomer initiator feed list

[0048]

[0049] a. Add the monomers in Table 1 except soybean oil to a four-neck flask equipped with stirring, thermometer and rectification column, control the temperature of the kettle not to exceed 230°C, and the temperature of the column at 95-100°C, and weigh after 2-4hrs of reaction The amount of water produced is less than 5mgKOH / g as measured by the acid value. Add soy oil and continue the reaction for 1-1.5hr. The measured acid value is less than 5mgKOH / g, and the temperature is lowered to 110°C.

[0050] b. At 110°C, methyl methacrylate (MMA), butyl acrylate (BA), lauryl methacrylate (LMA), glycidyl methacrylate (GMA), isobornyl methacrylate ( IBOMA) and other monomers and tert-butyl peroxybenzoate (TBPB) were mixed evenly, and added dropwise into a three-necked bottle for 2 to 2.5 hours. After the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com