Epoxy sealing agent for timber product and preparation method and application thereof

A technology of epoxy woodware and sealant, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of low hardness, paint film collapse, and affect the appearance, and achieve good storage stability, low VOC emissions, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

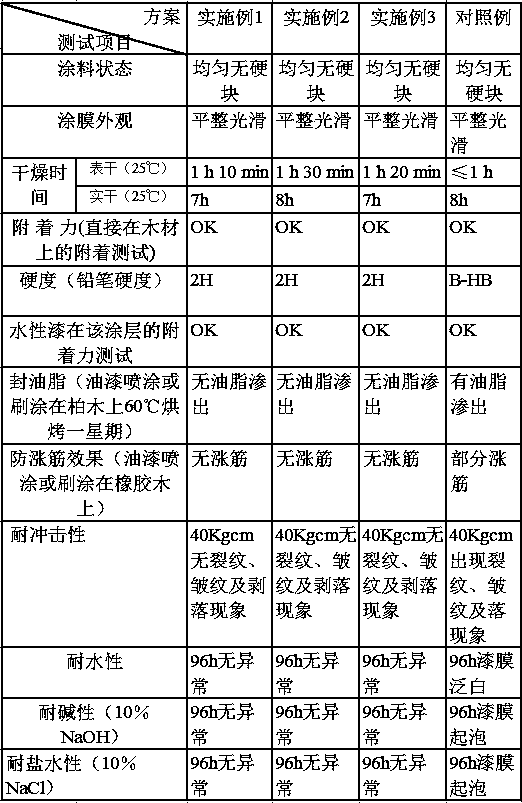

Examples

Embodiment 1

[0045] Preparation of component A: Weigh 100kg in total according to the mass percentage: 52kg of water-based epoxy emulsion, 18kg of epoxy-acrylic emulsion, 0.2kg of pH regulator, 0.3kg of defoamer, 2kg of filler, 1.2kg of thickener, flow Leveling agent 0.3kg, wetting agent 0.4kg, water 25.5kg.

[0046] After weighing the raw materials according to the above mass components, proceed according to the following steps:

[0047] A. Add water-based epoxy emulsion, epoxy-acrylic emulsion, pH adjuster, thickener, defoamer to the dispersing tank in sequence, stir and disperse at high speed for 10 minutes until the viscosity of the emulsion increases significantly;

[0048] B. In step A, add fillers in turn, stir and disperse for 10-15 minutes, until the fineness is ≤50 μm;

[0049] C. Add leveling agent, wetting agent, and water in step B to make the viscosity of the sealing agent to 155s-180s, stir at a medium speed for 5 minutes until uniform, then filter and pack.

[0050] Prepa...

Embodiment 2

[0055] Preparation of component A: Weigh 100kg in total according to mass percentage: 56kg of water-based epoxy emulsion, 19kg of epoxy-acrylic emulsion, 0.2kg of pH regulator, 0.2kg of defoamer, 4kg of filler, 0.8kg of thickener, flow Leveling agent 0.3kg, wetting agent 0.5kg, water 19kg.

[0056] After weighing the raw materials according to the above mass components, proceed according to the following steps:

[0057] A. Add water-based epoxy emulsion, epoxy-acrylic emulsion, pH adjuster, thickener, defoamer to the dispersing tank in sequence, stir and disperse at high speed for 10 minutes until the viscosity of the emulsion increases significantly;

[0058] B. In step A, add fillers in turn, stir and disperse for 10-15 minutes, until the fineness is ≤50 μm;

[0059] C. Add leveling agent, wetting agent, and water in step B to make the viscosity of the sealing agent to 155s-180s, stir at a medium speed for 5 minutes until uniform, then filter and pack.

[0060]Preparation ...

Embodiment 3

[0065] Preparation of component A: Weigh 100kg in total according to the mass percentage: 49kg of water-based epoxy emulsion, 16kg of epoxy-acrylic emulsion, 0.2kg of pH regulator, 0.2kg of defoamer, 3kg of filler, 1.5kg of thickener, flow Leveling agent 0.3kg, wetting agent 0.5kg, water 29.3kg.

[0066] After weighing the raw materials according to the above mass components, proceed according to the following steps:

[0067] A. Add water-based epoxy emulsion, epoxy-acrylic emulsion, pH adjuster, thickener, defoamer to the dispersing tank in sequence, stir and disperse at high speed for 10 minutes until the viscosity of the emulsion increases significantly;

[0068] B. In step A, add fillers in turn, stir and disperse for 10-15 minutes, until the fineness is ≤50 μm;

[0069] C. Add leveling agent, wetting agent, and water in step B to make the viscosity of the sealing agent to 155s-180s, stir at a medium speed for 5 minutes until uniform, then filter and pack.

[0070] Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com