High-wear-resistance self-recovery rubber-feel plastic paint, and production and construction methods thereof

A plastic coating, high wear-resistant technology, applied in polyurea/polyurethane coatings, coatings, devices for coating liquid on the surface, etc., to achieve the effects of reducing pollution, saving coating production costs, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

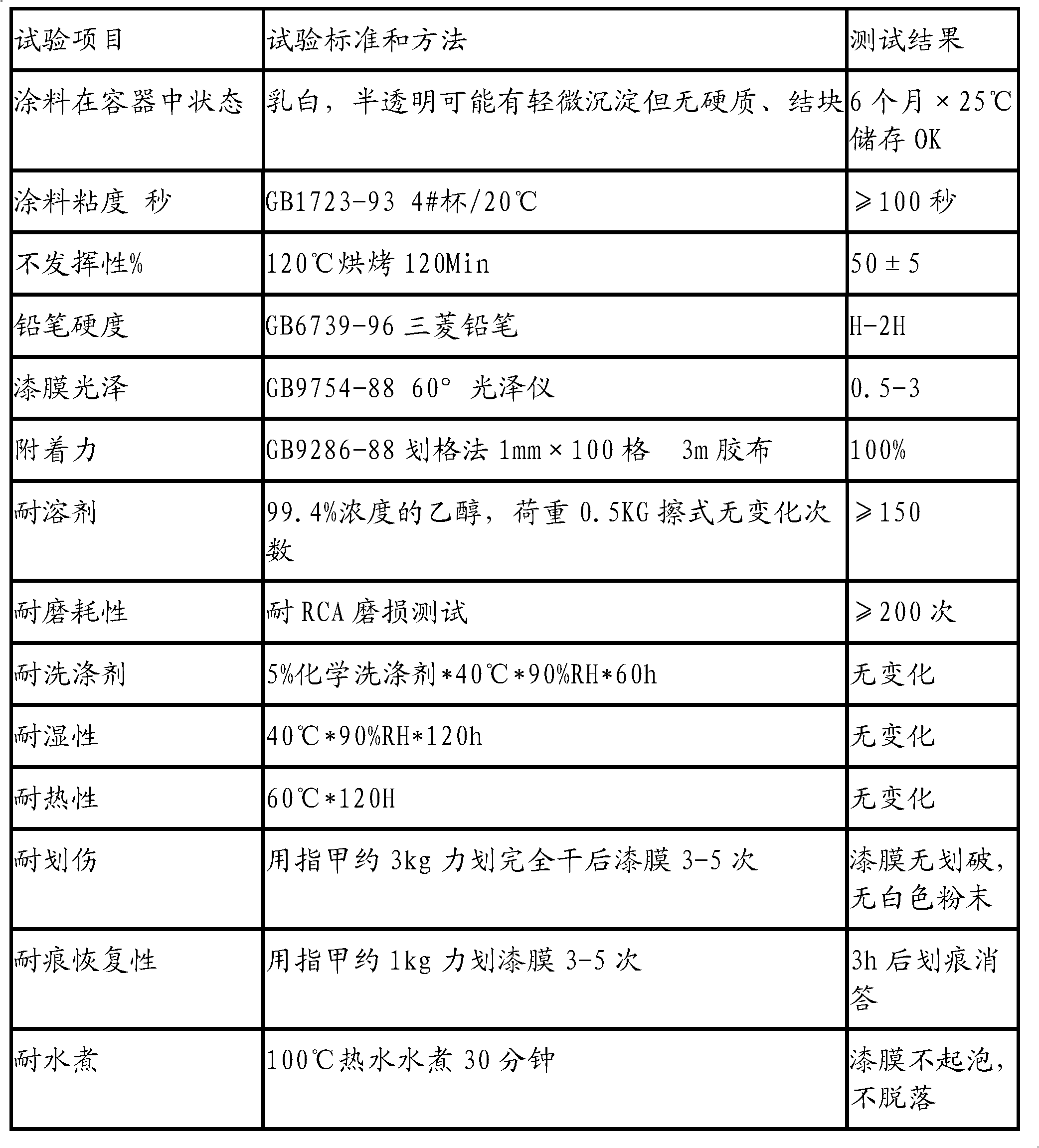

Image

Examples

Embodiment 1

[0053] The coating described in the application of the present invention comprises main agent, diluent and curing agent, wherein main agent comprises the various compositions of following weight portion:

[0054] 1. Two-component polyurethane resin A 15 parts;

[0055] 2. Two-component polyurethane resin B 15 parts;

[0056] 3. The concentration is 5 parts of 10% dibutyltin laurate (dissolved in butanone);

[0057] 4. 6 parts of matte powder;

[0058] 5. 0.5 parts of polyacrylate leveling agent;

[0059] 6. 15 parts of ethyl acetate;

[0060] 7. 15 parts of butyl acetate;

[0061] 8. 10 parts of toluene.

[0062] The diluent consists of 40% diacetone acrylamide and 60% ethyl acetate by mass, and the curing agent is polyisocyanate trimer.

Embodiment 2

[0064] The coating described in the application of the present invention comprises main agent, diluent and curing agent, wherein main agent comprises the various compositions of following weight portion:

[0065] 1. Two-component polyurethane resin A 17.5 parts;

[0066] 2. Two-component polyurethane resin B 17.5 parts;

[0067] 3. The concentration is 10% dibutyltin laurate (dissolved in butanone) 10 parts;

[0068] 4. 7.5 parts of matte powder;

[0069] 5. Polyacrylate leveling agent 1 part;

[0070] 6. 20 parts of ethyl acetate;

[0071] 7. 20 parts of butyl acetate;

[0072] 8. 15 parts of toluene.

[0073] The diluent is composed of diacetone acrylamide (DAA) and ethyl acetate, wherein the mass percentage of diacetone acrylamide is 50%, and the mass percentage of ethyl acetate is 50%; the curing agent is polyisocyanate trimer.

Embodiment 3

[0075] The coating described in the application of the present invention comprises main agent, diluent and curing agent, wherein main agent comprises the various compositions of following weight portion:

[0076] 1. Two-component polyurethane resin A 17 parts;

[0077] 2. 17 parts of two-component polyurethane resin B;

[0078] 3. The concentration is 7 parts of 10% dibutyltin laurate (dissolved in butanone);

[0079] 4. 7 parts of matte powder;

[0080] 5. 0.8 parts of polyacrylate leveling agent;

[0081] 6. 2 parts of epoxy-modified polysiloxane;

[0082] 7. 17 parts of ethyl acetate;

[0083] 8. 18 parts of butyl acetate;

[0084] 9. 12 parts of toluene.

[0085] The diluent is composed of diacetone acrylamide (DAA) and ethyl acetate, wherein the mass percentage of diacetone acrylamide is 45%, and the mass percentage of ethyl acetate is 55%; the curing agent is more than Isocyanate trimer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com