Polymer emulsion for waterborne metal anticorrosive coating and preparation method of polymer emulsion

A polymer emulsion and metal anti-corrosion technology, applied in the field of emulsion, can solve the problems of coating film voids, incompleteness, coating water resistance, poor salt spray resistance, etc., and achieve the effect of improving salt water resistance, water resistance, and density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

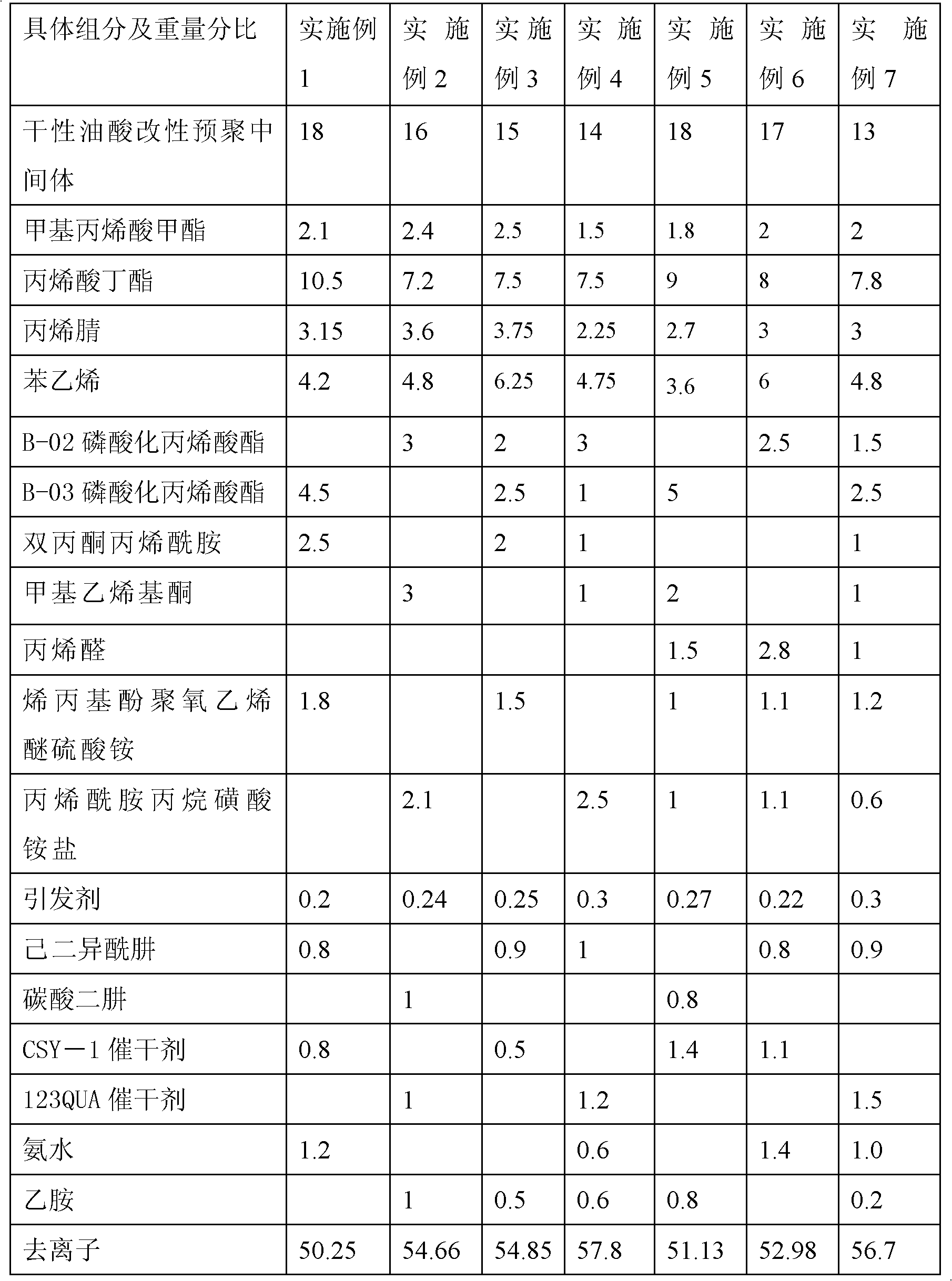

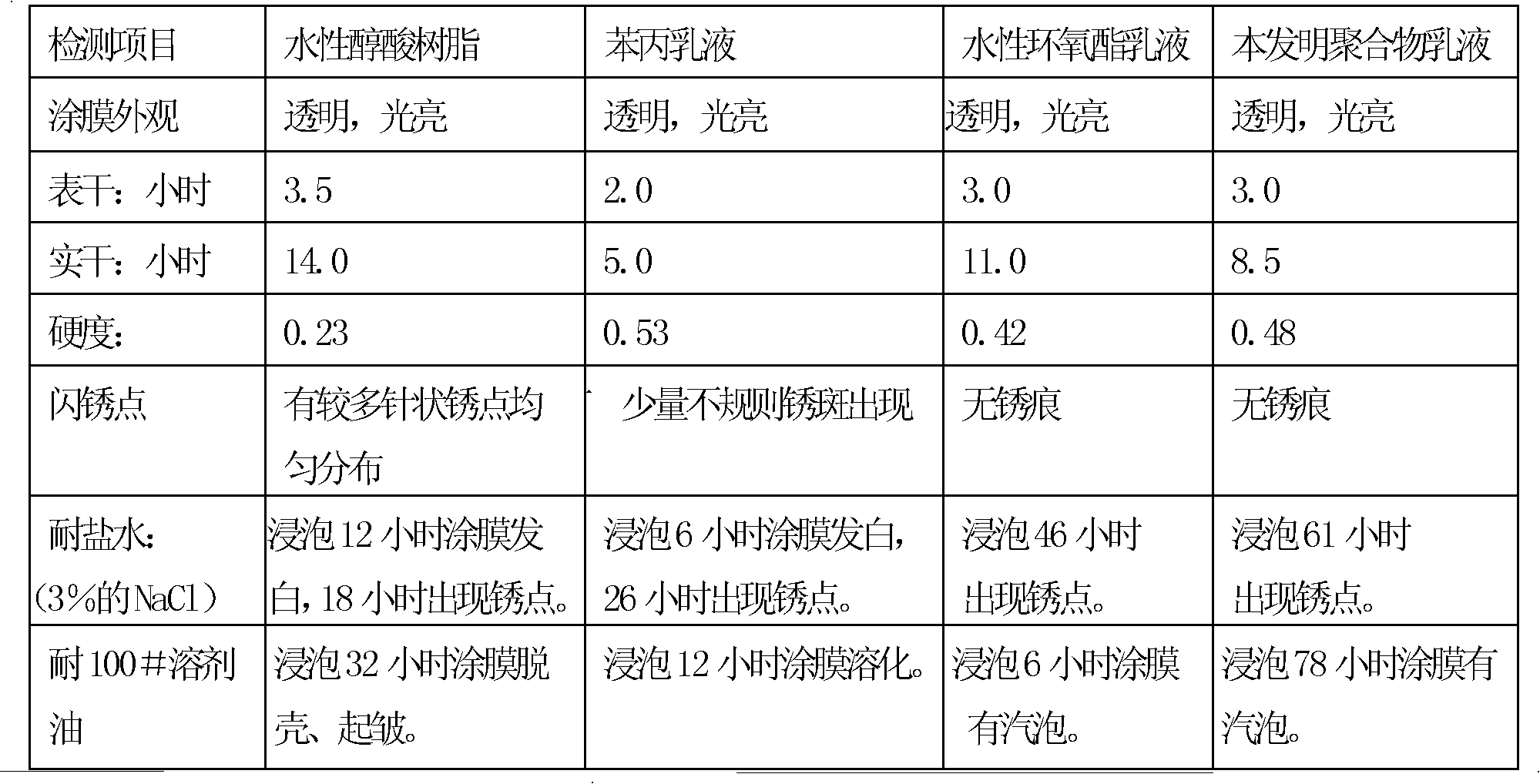

[0031]A polymer emulsion for water-based metal anti-corrosion coating of the present invention, its raw material is composed of the following components in mass percentage, including 13.0-18.0% dry oleic acid modified pre-polymerization intermediate, 16.0-20.0% acrylate monomer body, 2.0-3.0% functional monomer containing ketone carbonyl group, 2.5-5.0% modified acrylate monomer, 1.5-2.5% reactive emulsifier, 0.2-0.3% initiator, 0.8-1.0% The compound containing hydrazine group, 0.5-1.5% of water-based drier, 0.5-1.2% of volatile base and the balance of deionized water, the above-mentioned raw materials can be purchased in the market.

[0032] Wherein, the dry oleic acid modified prepolymerization intermediate of the present invention includes dry oleic acid, acrylic acid monomer, epoxy resin and stannous octoate and polymerization inhibitor used for esterification catalysis, dry oleic acid modified prepolymerization The raw materials of the polyintermediate include 18.0-20.0% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com