Enhanced performance of the dehydrogenation by the reduction of coke formation using pre-activated co2

A dehydrogenation and dehydrogenation reactor technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of expensive and time-consuming catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

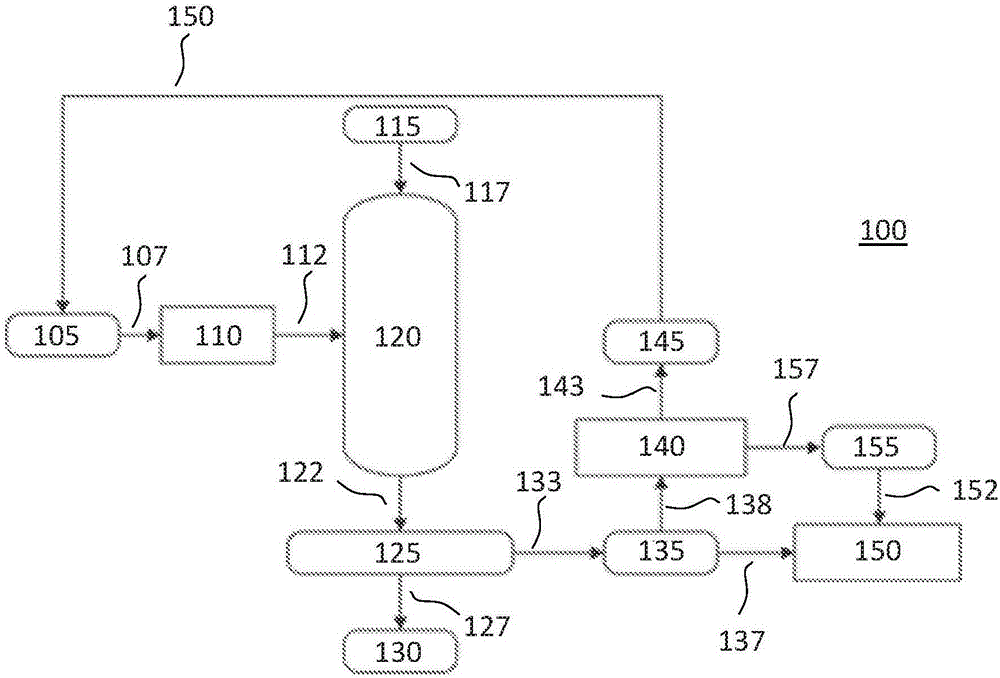

Image

Examples

Embodiment approach 1

[0048] Embodiment 1: A method for obtaining olefins, comprising: allowing a first reactant stream comprising alkanes to enter a dehydrogenation reactor through a first inlet; allowing activated CO 2 The second reactant stream is passed through a second inlet into a dehydrogenation reactor where the first reactant stream and the second reactant stream are reacted over a dehydrogenation catalyst under conditions that convert alkanes to alkenes; and Olefins are recovered.

Embodiment approach 2

[0049] Embodiment 2: The method according to Embodiment 1, wherein the activated CO 2 produced by a plasma reactor.

Embodiment approach 3

[0050] Embodiment 3: The method according to Embodiment 2, wherein the plasma reactor is a non-thermal plasma reactor selected from dielectric barrier discharge reactors, glow discharge reactors, corona discharge reactors, silent discharge reactors, microwave discharge reactor, and radio frequency discharge reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com