Sieving and crushing integrated machine

An all-in-one machine and crusher technology, which is applied in the fields of filter screen, magnetic separation, solid separation, etc., can solve the problems of large workload of maintenance, repair and replacement of tooth plates, insufficient output, and unadjustable discharge particle size, etc., to reduce equipment maintenance. The amount of maintenance, the convenience of replacing spare parts, and the effect of reducing the power consumption of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with accompanying drawing:

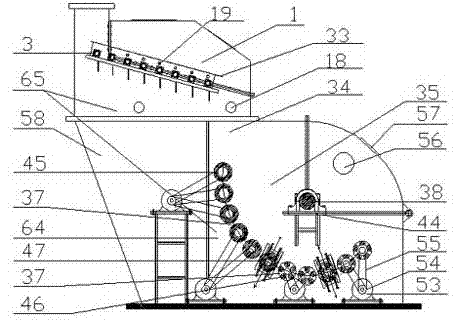

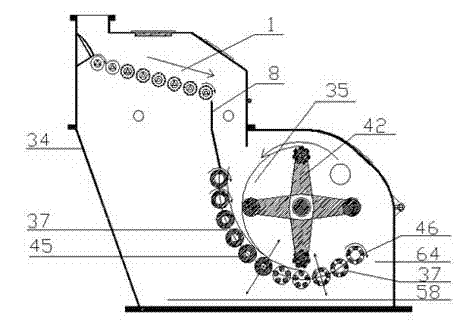

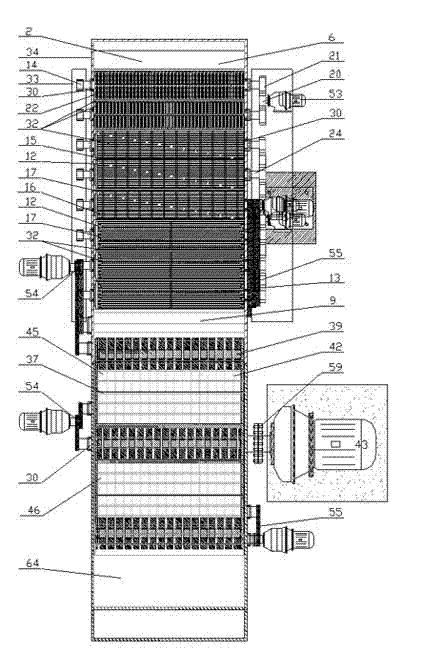

[0092] Such as figure 1 , figure 2 The shown integrated screening and crushing machine includes the screening and distributing machine 1 at the upper end of the casing 34, and the screening and crushing machine 35 at the lower end of the casing is combined into a screening and crushing integrated machine 65. image 3 As shown, there is an arc-shaped distribution plate 6 under the inlet 2 of the sieve distribution machine, and the screen surface is below the arc-shaped distribution plate. The sieve surface composed of the shaft 3 is at an inclination angle of 0-75° to the horizontal plane. The diameter, length and clearance of the sieve slit 32 of the sieve shaft 3 are uniform. The sieve strips 23 are combined, and its flange pieces 22 and flange pieces 22 are interlaced to form a sieve 32. The filter sieve shaft 5 is formed by a sieve bar 17, a filter sieve bar 26, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com