Energy-saving type crushing machine of discharging pipeline of cement bunker

A discharge pipeline and cement storage technology, applied in grain processing, etc., can solve the problems of reducing the quality of cement products, wasting electric energy, and poor crushing effect of cement blocks, and achieves the effects of simple structure, low power consumption, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

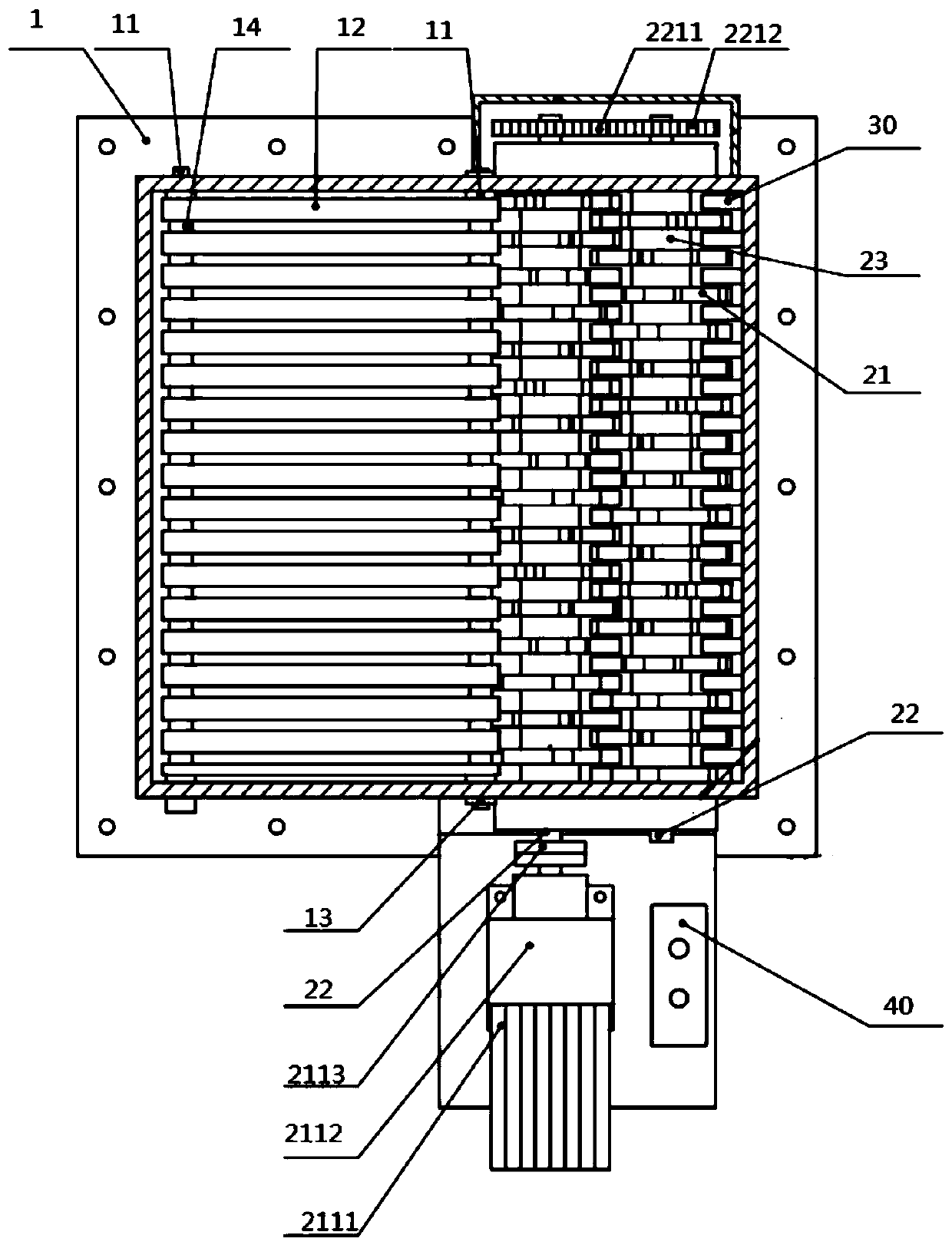

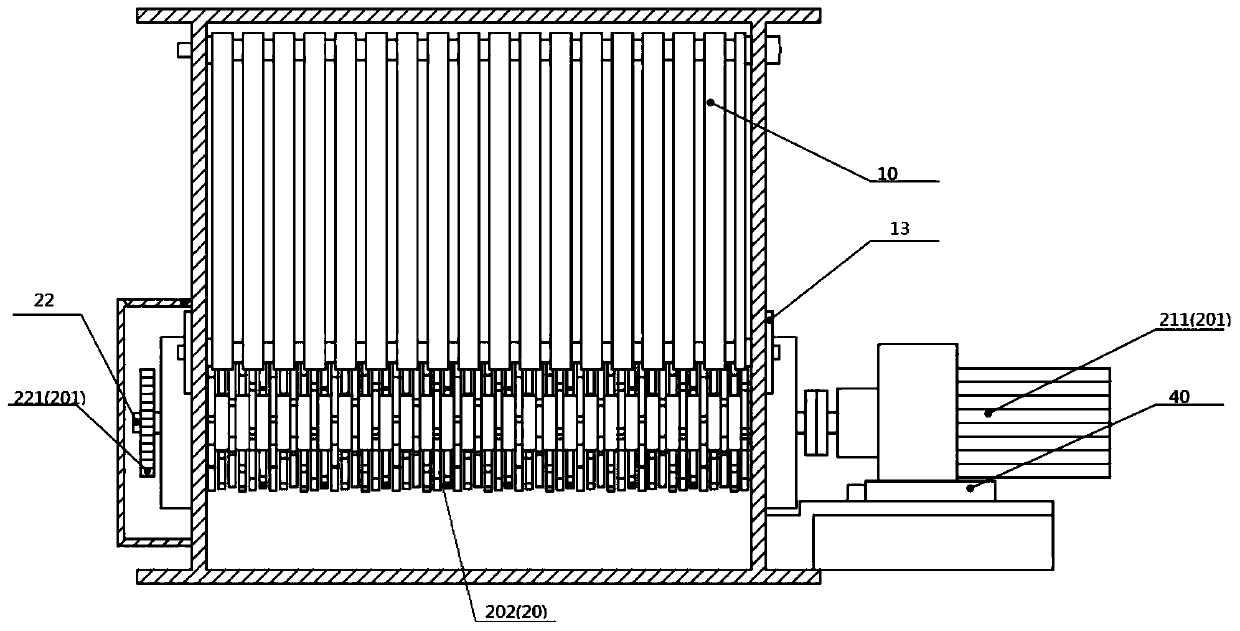

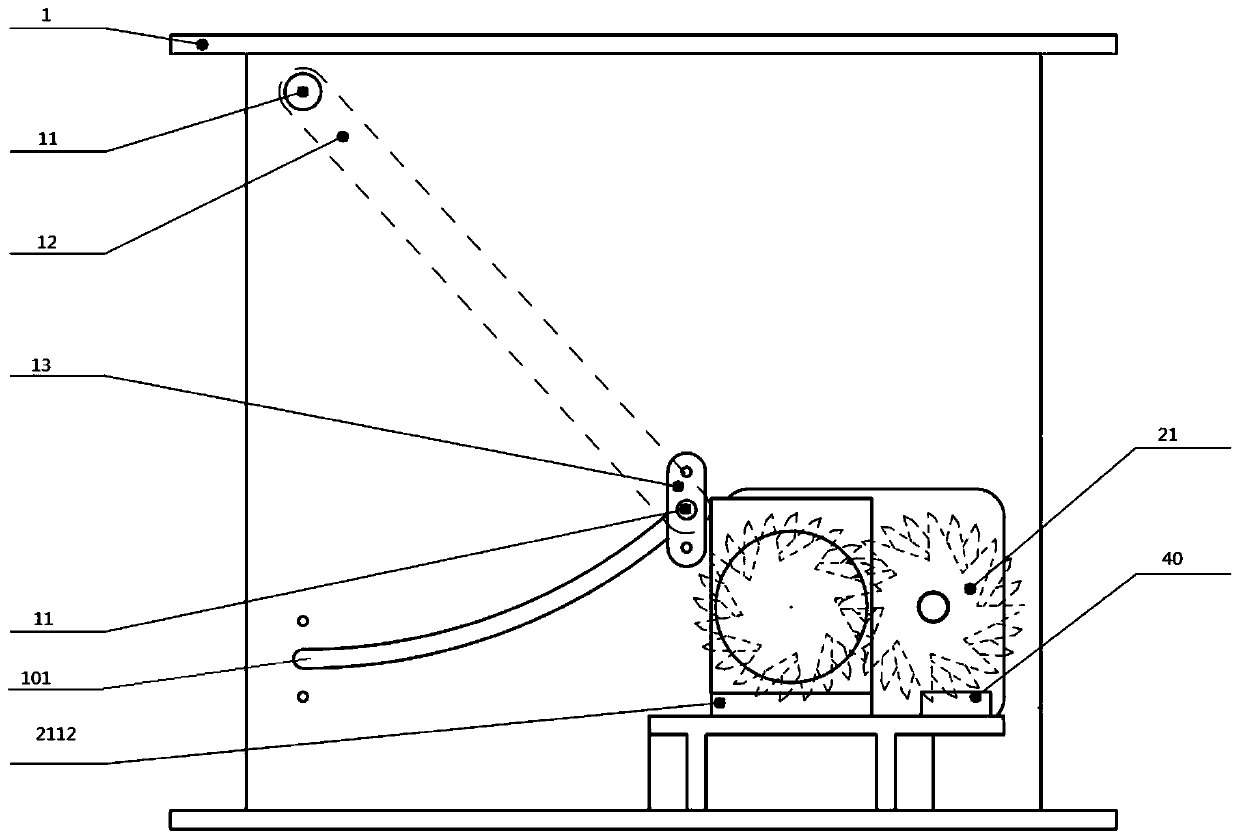

[0034] Please check Figure 1 to Figure 3 , an energy-saving cement silo discharge pipe crusher installed at the discharge port of cement silo 1; it includes a sieve plate 10 that can open or cover the upper part of the discharge port and a crushing mechanism 20 that covers the lower part of the discharge port, the sieve plate 10 is evenly arranged on its covering surface with a plurality of sieve holes for unhardened cement to pass through, and the crushing mechanism 20 is equipped with a plurality of power-driven crushing cutter wheels 21 for crushing hardened cement blocks on its covering surface. The hardened cement block sieved out by the sieve plate 10 slides down to the crushing mechanism 20 below under the action of its own weight and is broken by the crushing mechanism 20 and exported to the cement storehouse 1 . The lower end surface of the sieve plate 10 covering the discharge port is closely connected with one end face of the crushing mechanism 20 to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com