Powder resin desorption regeneration reactor

A powder resin and reactor technology, which is applied in the field of powder resin desorption regeneration reactor, can solve the problems of low resin strength, separation of liquid and resin, etc., and achieve the effect of low manufacturing cost, sufficient separation, and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

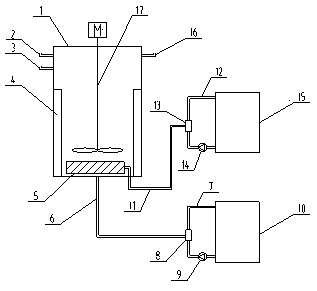

[0035] Reactor 1 is a steel or fiberglass structure with a diameter of 1.4-1.6m and a height of 2.0-3.0m; the water baffle 4 is located inside the reactor and two pieces are installed axially symmetrically from the bottom of the raw reactor, and the height of the water baffle is 1.5 ~2.4m, width 50~80mm; the center of the upper part of the reactor is equipped with a steel or fiberglass structure propeller blade agitator 17, the length of which is 0.7~1.5m, the diameter is 0.5~0.8m, by adjusting the speed of the agitator 30-120r / min can control the mixing intensity of resin and liquid in the reactor. The lower end of the reactor is provided with a resin separator 5, which is 1 to 4 hollow cylinders made of steel or glass fiber reinforced plastics with closed ends arranged in parallel along the radial direction of the reactor. The cylinders are connected in parallel to the desorption liquid discharge pipe 11, and a single The diameter of the cylinder is 150-200mm, and the surfa...

Embodiment 2

[0041] Compared with Embodiment 1, the difference of this embodiment is that the screen mesh tightly wound outside the surface of the cylinder is made of nylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com