Special shaped surface coal leveling device and use method thereof

A special-shaped surface, flat coal technology, applied in the field of mechanical design, can solve the problems of coal pushing to both sides of the carriage, low work efficiency, uneven coal discharge, etc., to achieve smooth and stable lifting and lowering, symmetrical coal discharge and Uniform and solve the effect of poor coal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

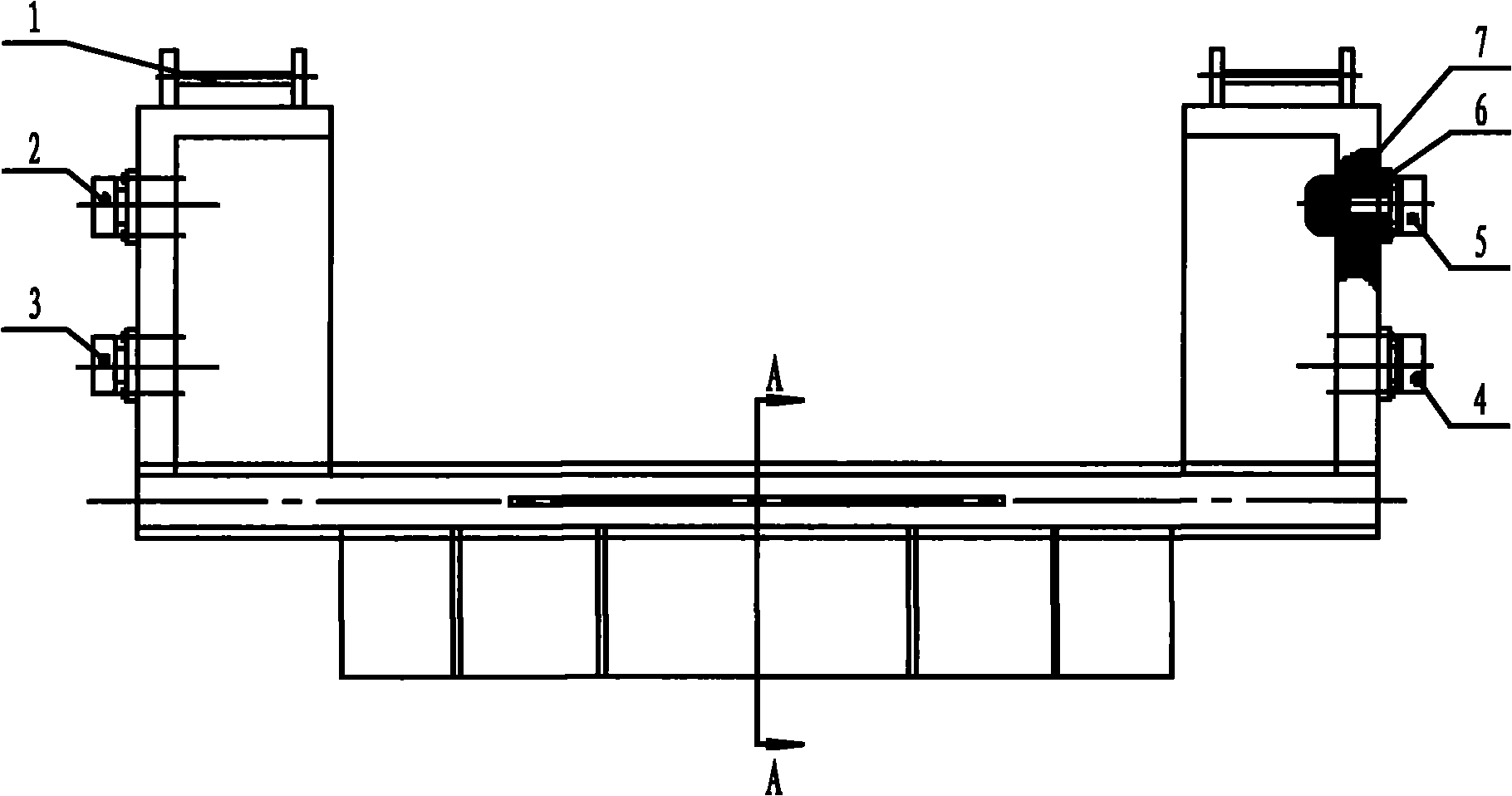

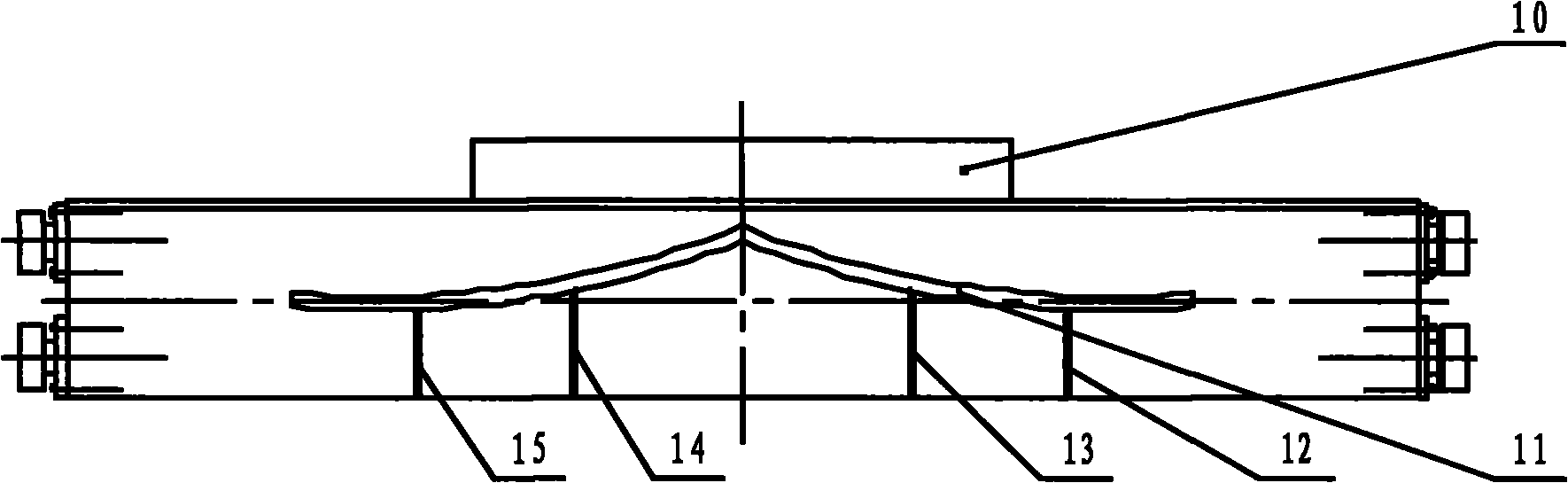

[0030] A special-shaped surface level coal device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

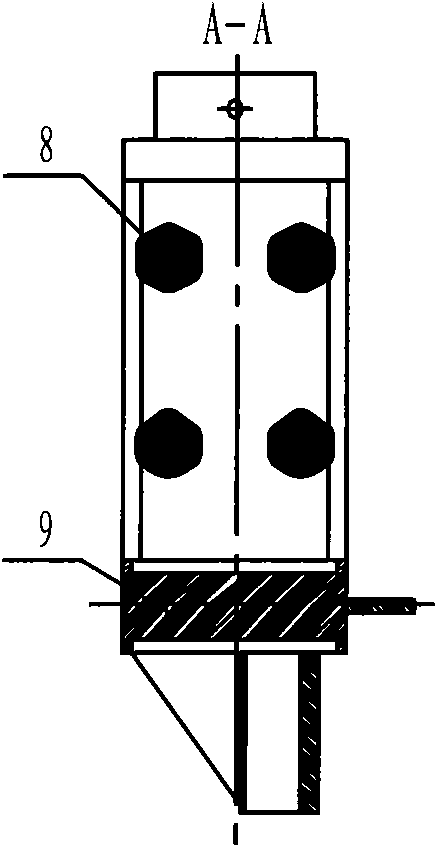

[0031] Such as figure 1 , 2 As shown in and 3: mainly composed of beam weldment 1, special-shaped flat coal scraper 11, U-shaped beam 9, upper coal retaining plate 10, first rib 12, second rib 13, third rib 14, the first Four ribs 15, left upper pulley group 2, left lower pulley group 3, right lower pulley group 4 and right upper pulley group 5, the special-shaped surface flat coal scraper 11 has the mathematical characteristics of the continuous second order derivative of the special-shaped curved surface The parabolic special-shaped surface scraper, its special-shaped flat coal scraper 11 is welded on the left and right sides, respectively equipped with four sets of pulley blocks, the left upper pulley block 2, the left lower pulley block 3, the right lower pulley block 4 and the right upper pulley block 5. On...

Embodiment approach 2

[0045] Embodiment 2: the length of the special-shaped surface flat coal scraper is taken as 2800mm, the height is taken as 600mm, and the thickness is taken as 50mm, and the parameters a, b and c of the parabolic mathematical function equation are taken as a=0.002 and b=0 respectively, c=0, the mathematical function equation of the parabola is y=0.002x 2 , the others are the same as in Embodiment 1.

Embodiment approach 3

[0046] Embodiment 3: the length of the special-shaped flat coal scraper is taken as 2700mm, the height is taken as 500mm, and the thickness is taken as 40mm, and the parameters a, b and c of the parabolic mathematical function equation are taken as a=0.003 and b=0 respectively, c=0, the mathematical function equation of the parabola is y=0.003x 2 , the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com