A method for demolding continuous extruded in-mold skinned pp foamed sheets

A foamed sheet and extrusion die technology, used in household appliances, other household appliances, flat products, etc., can solve the problems of large pull-out force, affect product quality, and large demoulding resistance, and achieve crystalline crust strength. The effect of increasing the strength of the crusted skin and reducing the vacuum adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

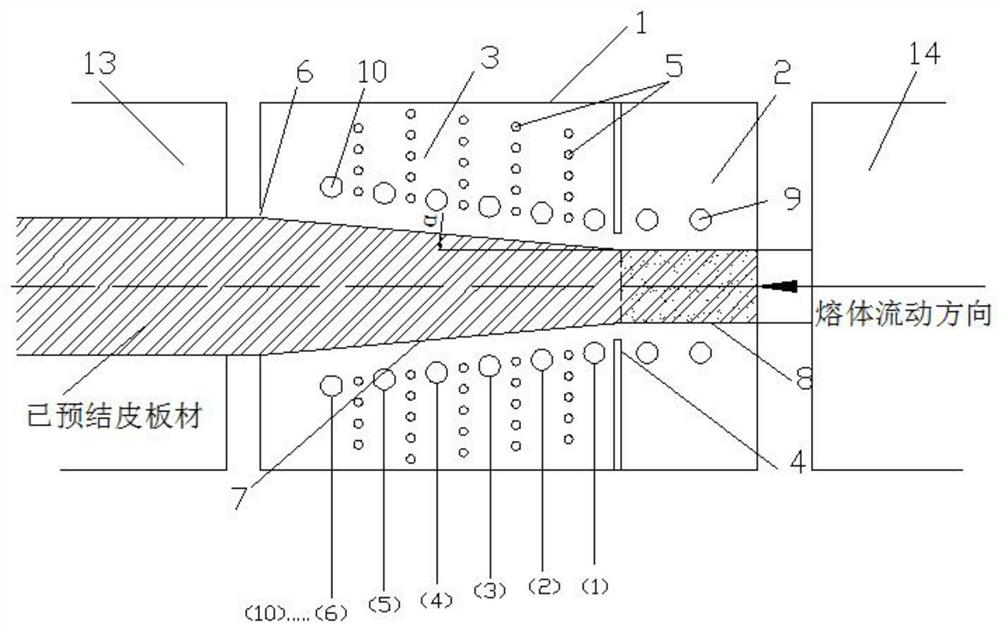

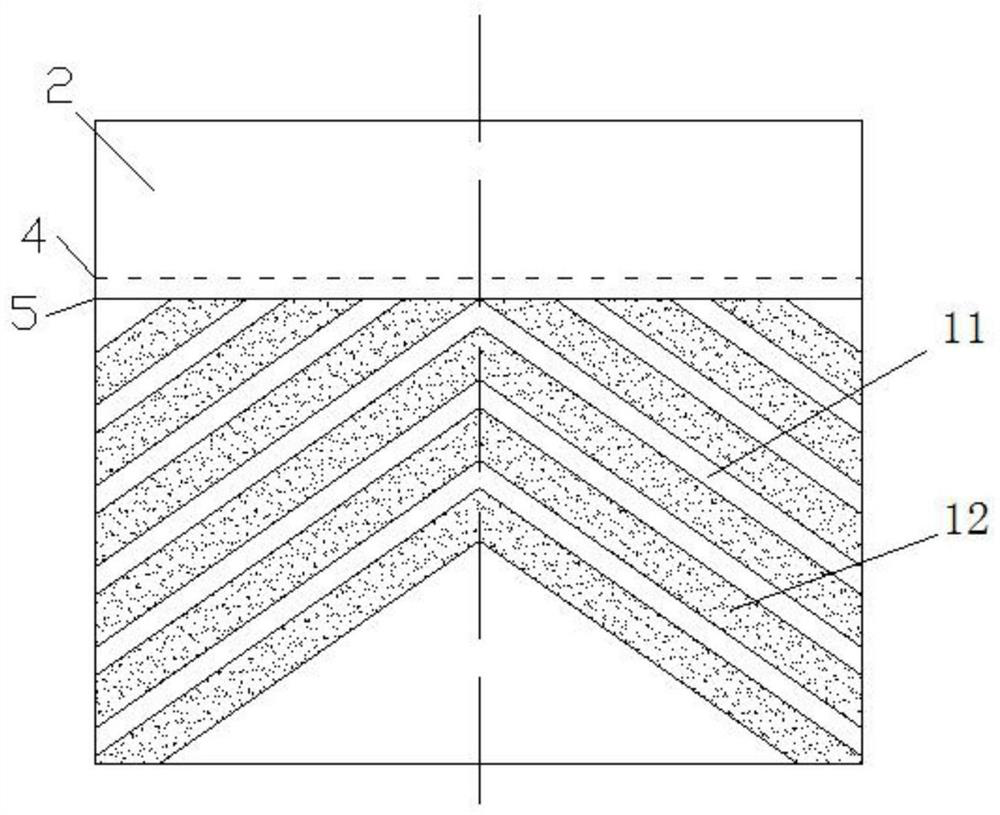

[0024] Please refer to Figure 1-2 As shown, the technical solution adopted in the present invention is: a demoulding method for continuously extruding in-mold skinned PP foamed sheets, the device used in the demoulding method is set as an enhanced crystal foaming device 1, and the enhanced The input end of the crystallization foaming device 1 is connected to the extruder 14, and the output end is connected to the shaping die 13. The enhanced foaming device 1 is divided into two parts, which are respectively a high-temperature runner area 2 and a pre-setting area 3. The high-temperature A temperature insulation groove 4 is provided between the flow channel area 2 and the preforming area 3, and a temperature insulating hole 5 is provided inside the preforming area 3, and the inner surface of the melt flow channel 6 is set as a differential crystal foaming surface 7, so The inner wall surface of the melt flow channel 6 in the high temperature flow channel area 2 is set as a flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com