Agar gel negative pressure perforating method and perforator

A technology of agar gel and pore former, which is applied in metal processing and other directions, can solve the problems of low drilling success rate and low work efficiency, and achieve the effects of high success rate, high work efficiency and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

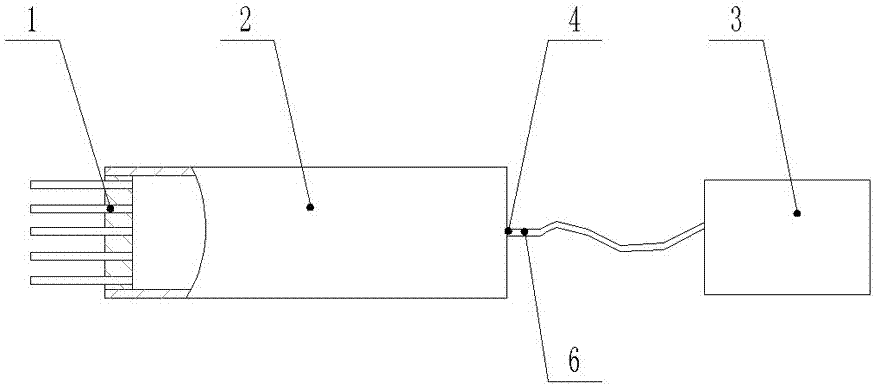

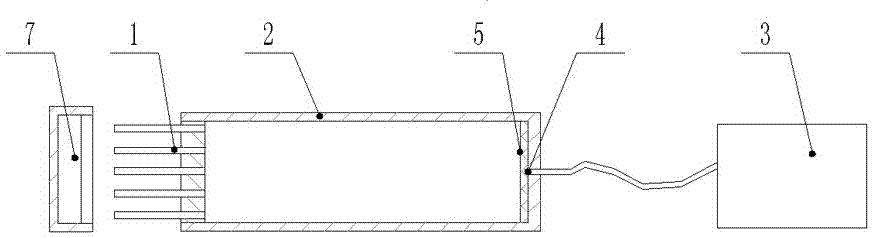

[0032] figure 1 and figure 2 In the shown negative pressure agar gel hole forming device, its structure is: the main body of the material 2 is a transparent cavity, one end of the main body of the material 2 is sealed and connected with the tail of the hole puncher 1, and the body of the material 2 is sealed. The other end is sealed and connected with the vacuum system 3; the material holding body 2 is a cavity that can hold gel particles. In this way, the inner cavity of the negative pressure agar gel pore forming device forms a closed chamber as a whole, and the vacuum system can work normally.

[0033] An anti-suction device 4 is arranged between the material main body 2 and the vacuum system 3 . The anti-suction device 4 is a channel 6 with a diameter smaller than the pinhole diameter of the puncher 1 . The anti-inhalation device can also be a filter screen 5, and the aperture of the filter screen 5 is smaller than the diameter of the pinhole of the puncher 1 . The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com