Paper box conveying equipment with flattening performance

A technology of transmission equipment and performance, applied in the direction of sending objects, stacking receiving devices, thin material processing, etc., can solve the problems of carton placement misalignment, carton deformation, and reduce the space utilization of cartons, so as to increase air Flow, reduce adsorption force, improve the effect of stacking flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

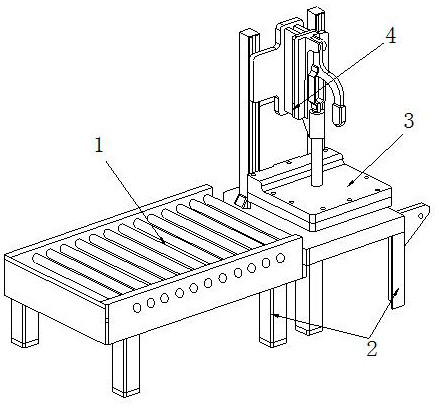

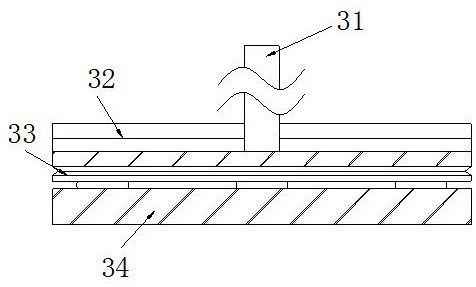

[0026] as attached figure 1 to attach Figure 4 Shown:

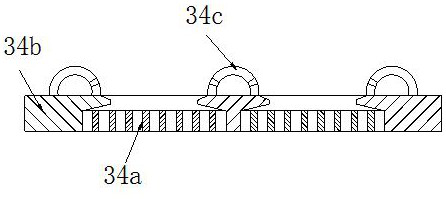

[0027] The present invention provides a carton conveying device with flattening performance, its structure includes a conveying roller 1, a base 2, a pressing plate 3, and a lower pressing rod 4, the conveying roller 1 is connected to the upper end of the base 2 with a shaft, and the The extrusion plate 3 is embedded and connected with the lower end of the lower pressure rod 4, and the left side of the base 2 is connected with the lower end of the left side of the lower pressure rod 4 by bolts. The contact plate 34, the support rod 31 is embedded and connected with the middle part of the shrinkage layer 33, the fixed plate 32 is welded and connected with the back side of the shrinkage layer 33, the contact plate 34 is connected with the lower side of the shrinkage layer 33, and the shrinkage layer 33 is wrinkled in shape and made of butyl rubber, which has the characteristics of high wear resistance and good recovery, ...

Embodiment 2

[0033] as attached Figure 5 to attach Figure 8 Shown:

[0034] Wherein, the air hole a3 includes a pipe column a31, an outer ring a32, a spring a33, and a fixed ring a34, the pipe column a31 is movably engaged with the inside of the main body plate a1, and the outer ring a32 is embedded and connected with the outside of the pipe column a31, The spring a33 is connected between the lower side of the outer ring a32 and the upper side of the fixed ring a34, the fixed ring a34 is embedded and connected with the main body plate a1, the shape of the outer ring a32 is a ring structure, and the shape of the fixed ring a34 is It is a ring structure, the outer diameter of the fixed ring a34 is larger than the outer diameter of the outer ring a32, and the inner diameter is the same, so that the outer ring a32 can move up and down on the upper side of the fixed ring a34, and the distance that the pipe string a31 can move downward is increased.

[0035]Wherein, the column a31 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com