Drained style sawtooth-shaped corrugated filler

A corrugated packing and sawtooth technology, applied in the field of new high-efficiency structured packing, can solve problems such as large pressure loss, achieve the effects of small pressure drop loss, enhanced gas-liquid interaction ability, and increased mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

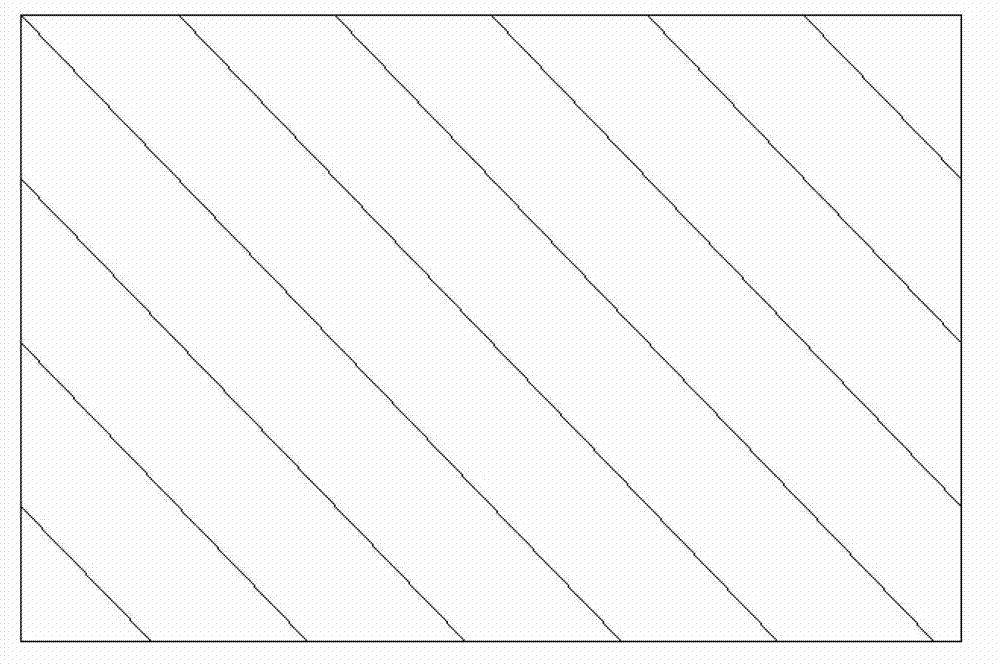

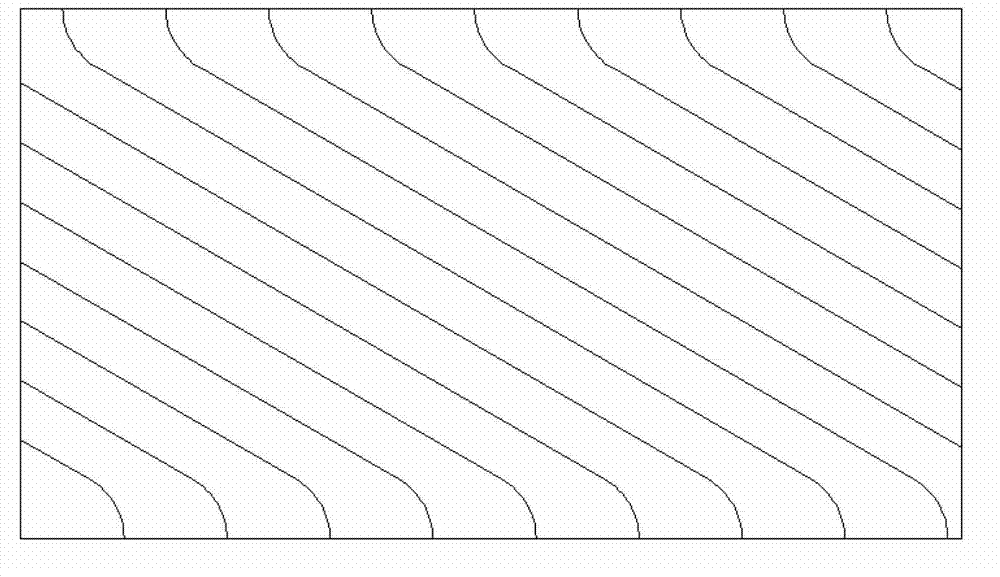

[0030] The structure of the present invention is as image 3 As shown, the corrugated packing is made of stainless steel plate, phosphor bronze plate, aluminum alloy plate or plastic sheet as a whole and pressed into a zigzag corrugated plate. The corrugated ridge line formed has an angle with the axial direction of the packing. The arc transitions to be parallel to the axial direction of the filler to achieve a smooth transition between the vapor and liquid boundaries.

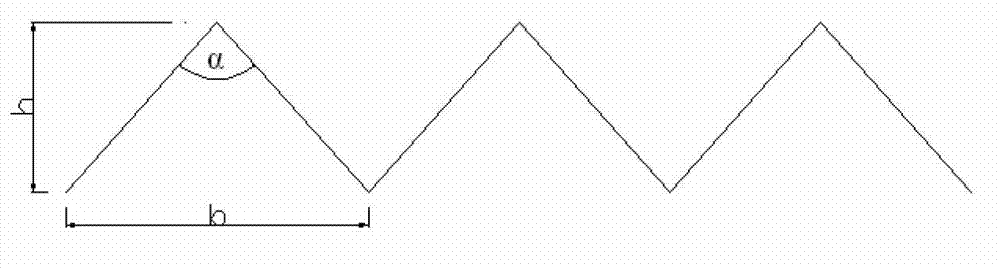

[0031] Among them, the longitudinal section of the corrugated ridge line is a right-angled triangle zigzag structure, and its structure is as follows: Figure 4 As shown, the peak height of the zigzag structure is 1.5mm-8mm, and the apex angle is 15°-75°. In addition, holes can be evenly opened on the surface of the corrugated packing to increase the gas-liquid lateral mixing performance. When in use, the corrugated packing can be bundled into a packing disc so that two adjacent packing sheets are staggered...

Embodiment 2

[0034] Isopropanol-water rectification separation, the diameter of the atmospheric rectification column is 1370mm. Punch a hole with a diameter of 5mm on the surface of the stainless steel plate, and the opening rate is 10%. Ridge such as Figure 4 shown. Cut and assemble into packing discs with a diameter of 1300 mm and a disc height of 300 mm, and fill them in the rectification tower. Under the same separation index, the separation efficiency of the packing technology of the present invention is 20% higher than that of the traditional metal plate corrugated packing, the pressure drop loss is 30% smaller, and the separation economic performance is greatly improved.

Embodiment 3

[0036] Preparation of Stable Isotopes by Cryogenic Distillation and Separation 13 c. Use 100-mesh stainless steel wire mesh to punch holes with a diameter of 3mm, with an opening rate of 5%, and roll the wire mesh sheet as a whole into a diversion-type sawtooth-shaped corrugated packing with a peak height of h=2.5mm and a tooth profile angle of α=45° , packing corrugation ridge line such as Figure 4 shown. Cut and assemble into packing discs with a diameter of 30 mm and a disc height of 30 mm. Filled with CO cryogenic distillation 13 C's packed tower. Compared with the traditional corrugated packing with the same peak height of 2.5mm, its mass transfer and separation efficiency is increased by 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com