Production process of strip-shaped black tea

A production process and technology for black tea, applied in the field of bar-shaped black tea production technology, can solve the problems of inconvenient laying of tea leaves and uneven oxygen contact, and achieve the effects of being easy to popularize and use, improving quality and reducing the amount of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

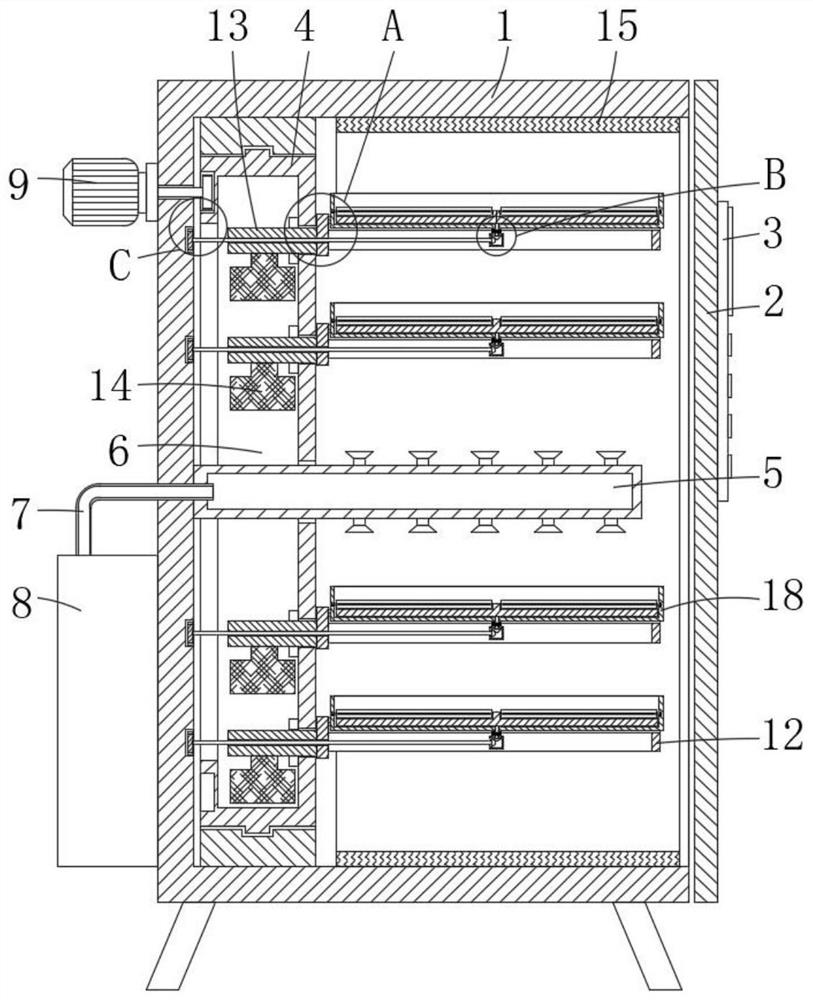

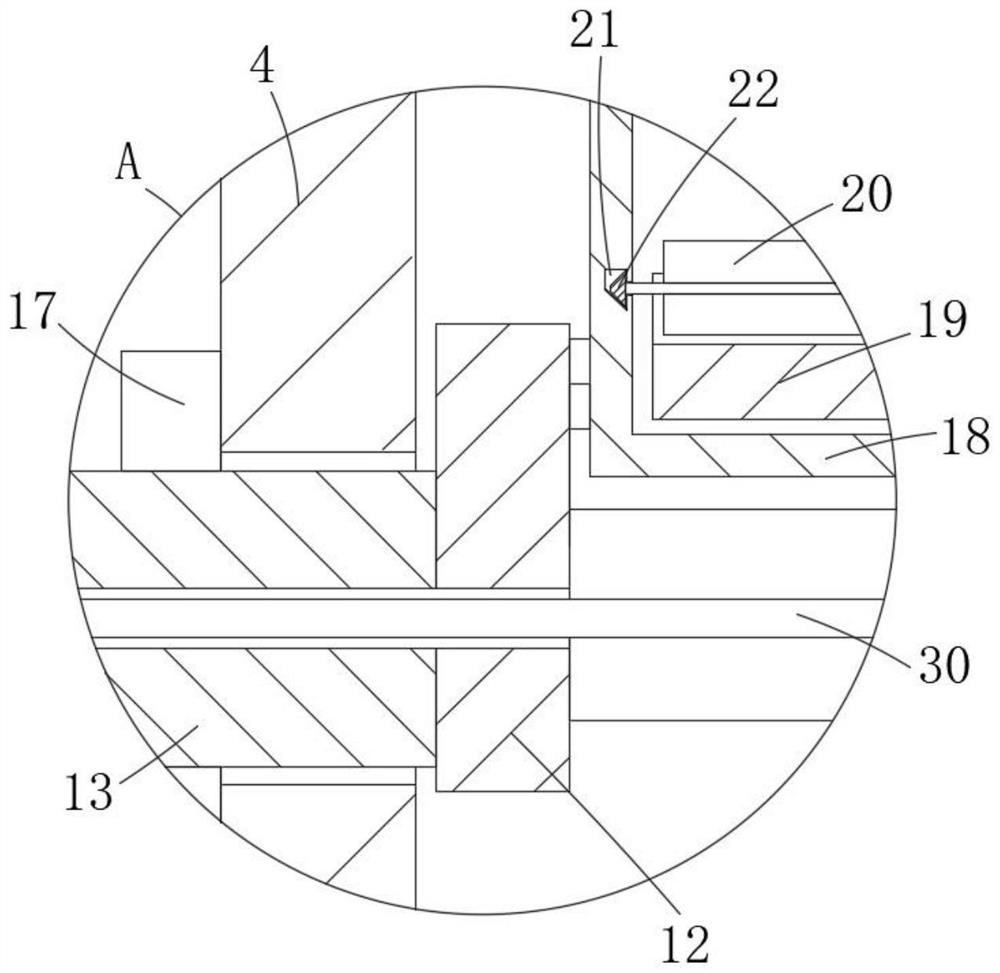

[0041] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

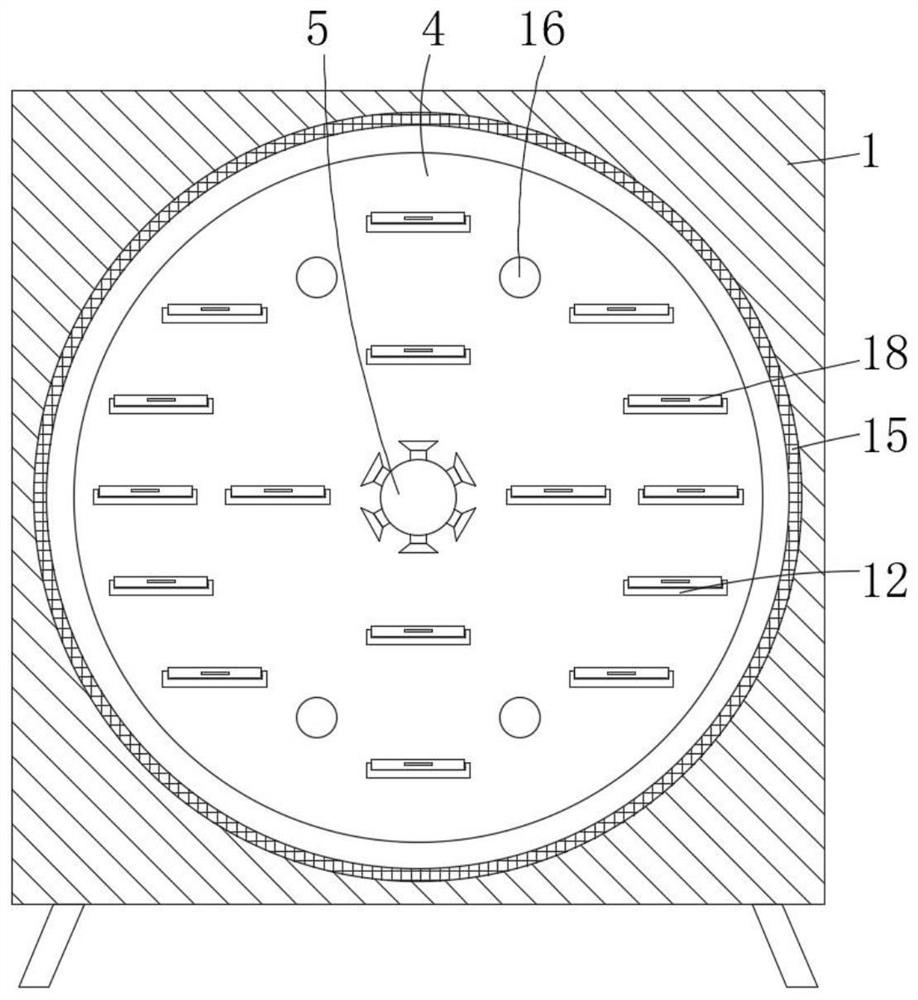

[0042] refer to Figure 1-8 , a bar-shaped black tea manufacturing process, comprising the following steps:

[0043] S1. Picking fresh leaves with one bud and two leaves or one bud and three leaves, and evenly aged and tender leaves;

[0044] S2. Clean the tea leaves obtained in the S1 step, and drain the water in the fresh leaves. During the cleaning process, first place the tea leaves in a sink for rinsing for 3-5 minutes, then collect the tea leaves after rinsing, and use a flowing Rinse the tea leaves after rinsing with water for 3-5 minutes, use a sieve to hold the tea leaves, and drain the tea leaves until there is no continuous water dripping;

[0045]S3. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com