Patents

Literature

38results about How to "Save construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

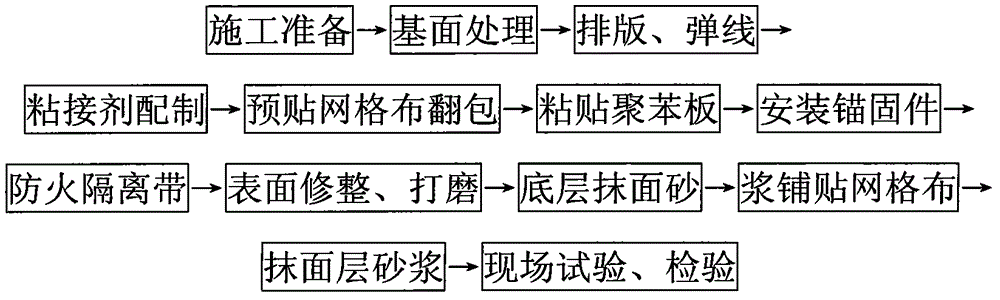

Method for external insulation construction of polystyrene board thin plastered surface in cold and windy area

InactiveCN104612261AKnots and effects are firm and stableImprove integrityCovering/liningsHeat proofingPolystyreneCement mortar

A method for external insulation construction of a polystyrene board thin plastered surface in a cold and windy area is characterized by comprising the steps of construction preparation, base surface processing, designing, line snapping, fire barrier arrangement, surface dressing and polishing, sand plastering of a bottom layer, mortar laying of gridding cloth, plastered surface mortar pouring and on-site testing and detection, 1:3 cement mortar is adopted for plastering and leveling after interface processing is conducted on a base layer, a wall is designed and divided through line snapping, an EPS board is attached with specific adhesive glue and fixed to the wall of the base layer under the assistance of an anchor bolt, detail enhancement is conducted, anti-crack mortar composite glass fiber gridding cloth is used as a protecting layer, and coating or decoration mortar serves as an external layer. Aiming at the special weather of the cold and windy area, by means of bonding between the EPS board and the wall, combination of the external layer and joint processing technology improvement, construction quality is guaranteed, a heat insulation material layer and a thin plastered surface layer are combined firmly and stably, integrality is high, the heat insulation performance of the exterior wall is improved, building materials are saved, and construction time is shortened.

Owner:YONGSHENG CONSTR GRP

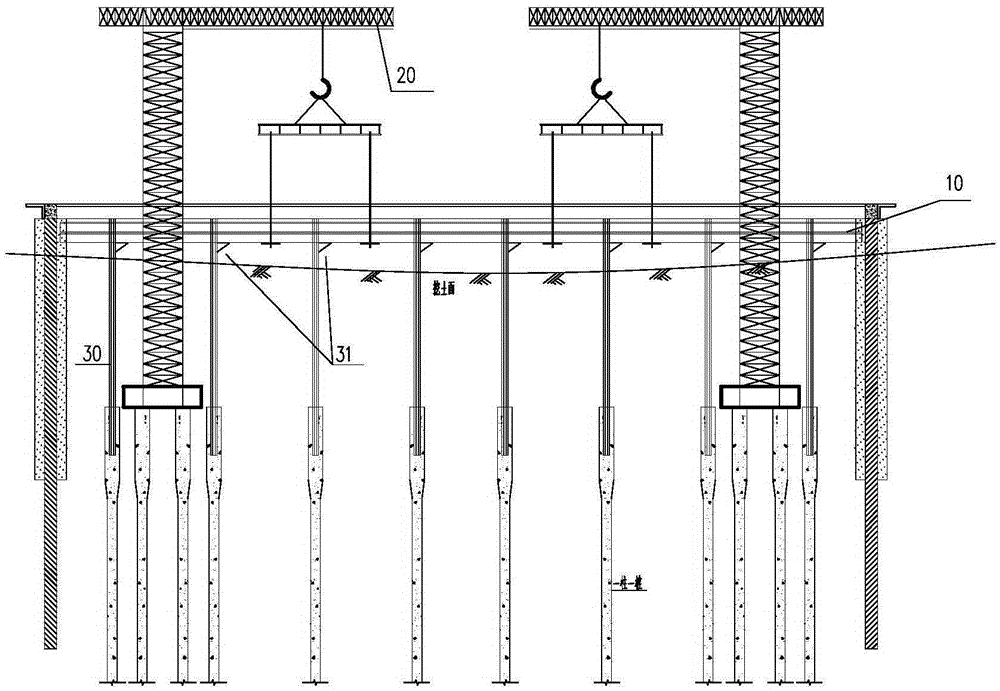

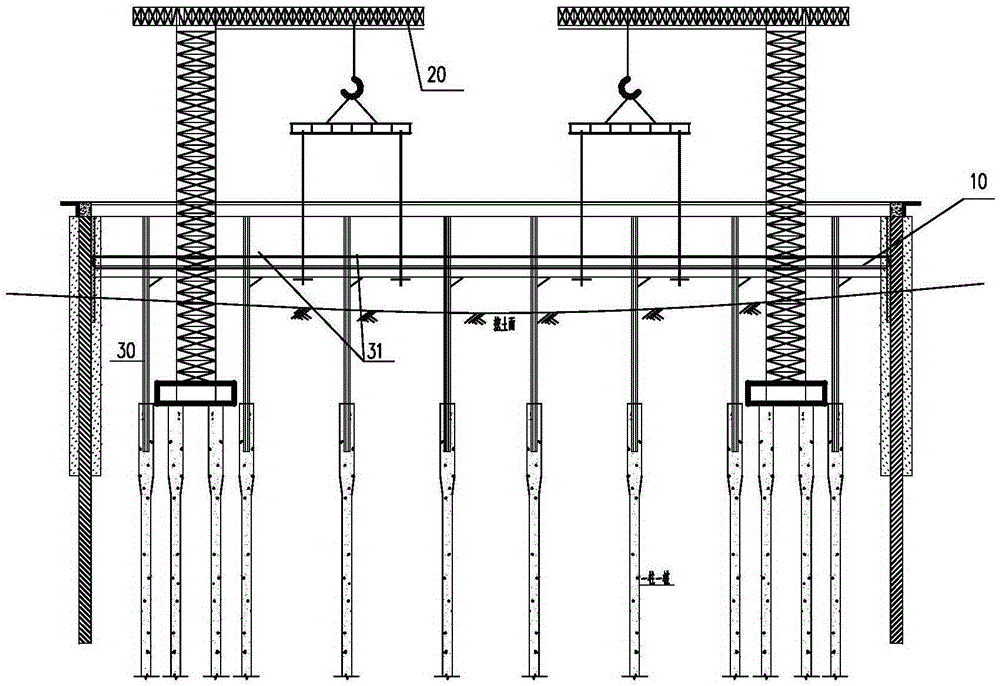

Floorslab construction method used during reverse building method construction

ActiveCN105350573AShort timeSolve the costArtificial islandsExcavationsBeam columnBuilding construction

The invention relates to a floorslab construction method used during reverse building method construction and belongs to the technical field of building engineering. The floorslab construction method used during reverse building method construction is used for solving the problems that during traditional reverse building method construction, a large number of underground cast-in-place beam slabs are constructed, and consequently, the construction period is long and cost is high. The construction method includes the steps that firstly, beam slab units in various layers are prefabricated before excavation of a foundation pit, and therefore a temporary prefabricated combined body which is vertically connected in a stacked manner is formed; secondly, the temporary prefabricated combined body is hoisted to the position above soil of the foundation pit and is placed on temporary supporting bases of latticed columns; thirdly, the soil of the foundation pit is excavated till a first layer of space is formed, the first layer of beam slab unit is fixedly installed, and meanwhile, pouring is conducted on beam column joints of the first layer of beam slab unit; fourthly, excavation continues till a second layer of space is formed, the remaining portion of the temporary prefabricated combined body is hoisted and fixed to latticed columns of the second layer of space, the second layer of beam slab unit is fixedly installed, and pouring is conducted on beam column joints at the position; and the steps are executed in a circulating manner in this way till the soil of the whole foundation pit is excavated and the Nth layer of beam slab unit is formed through pouring.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

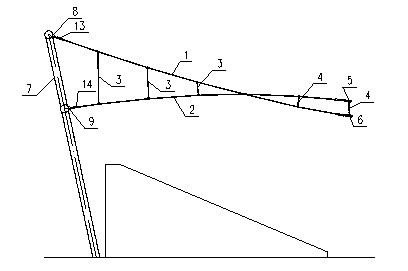

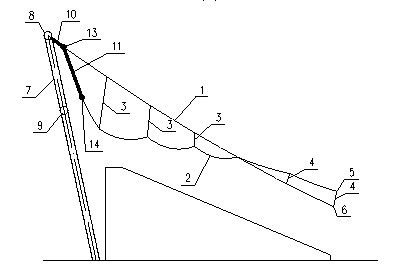

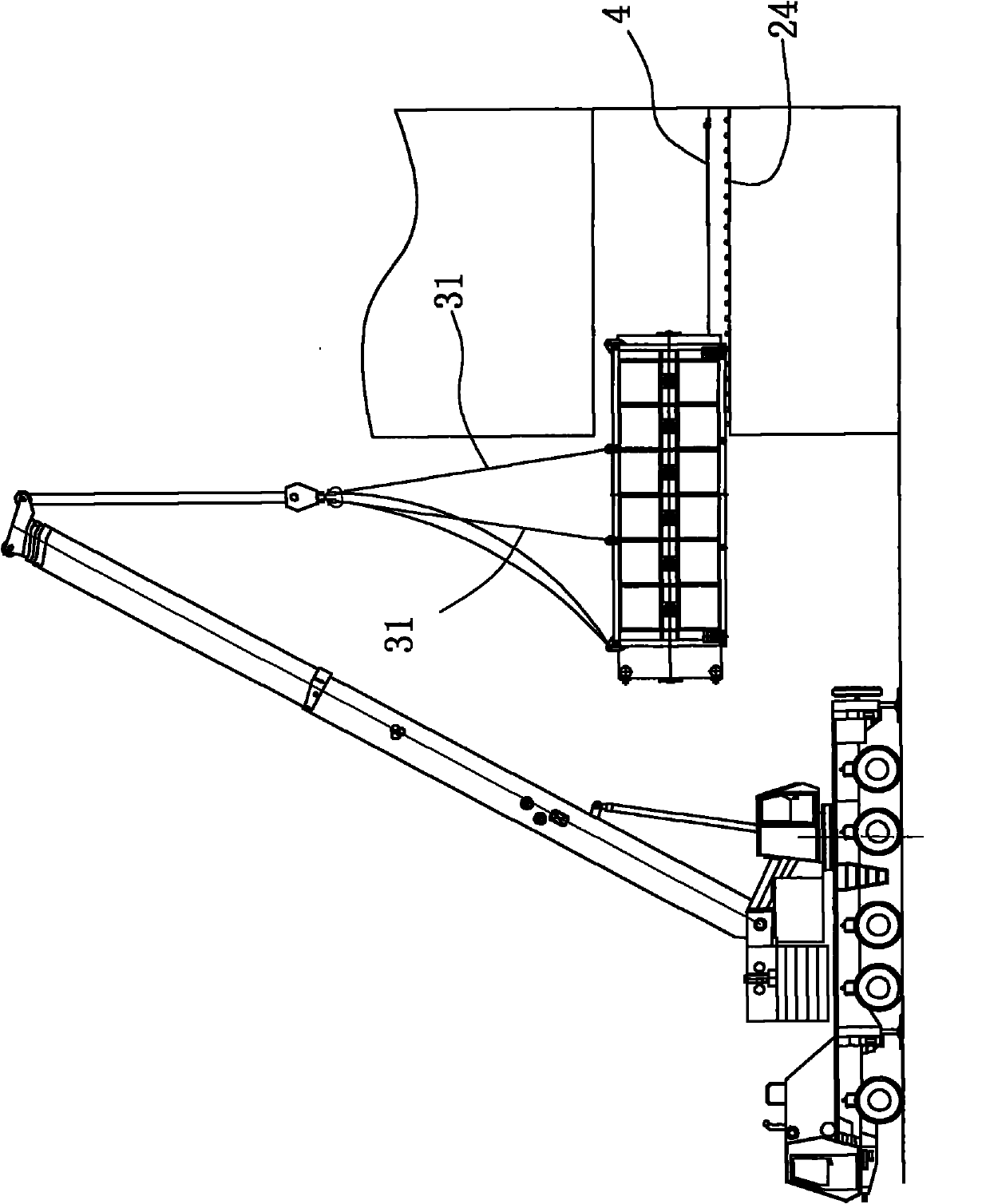

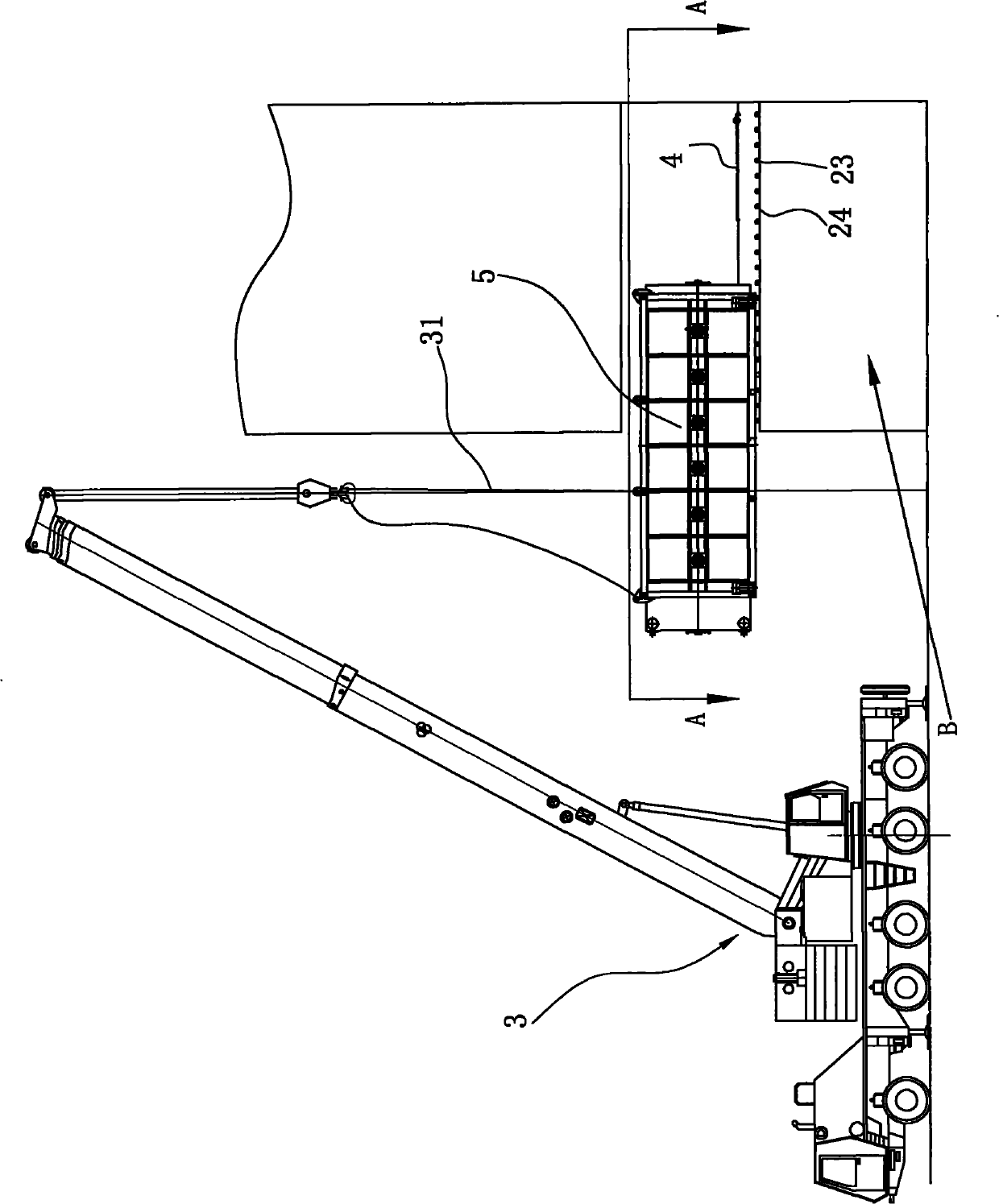

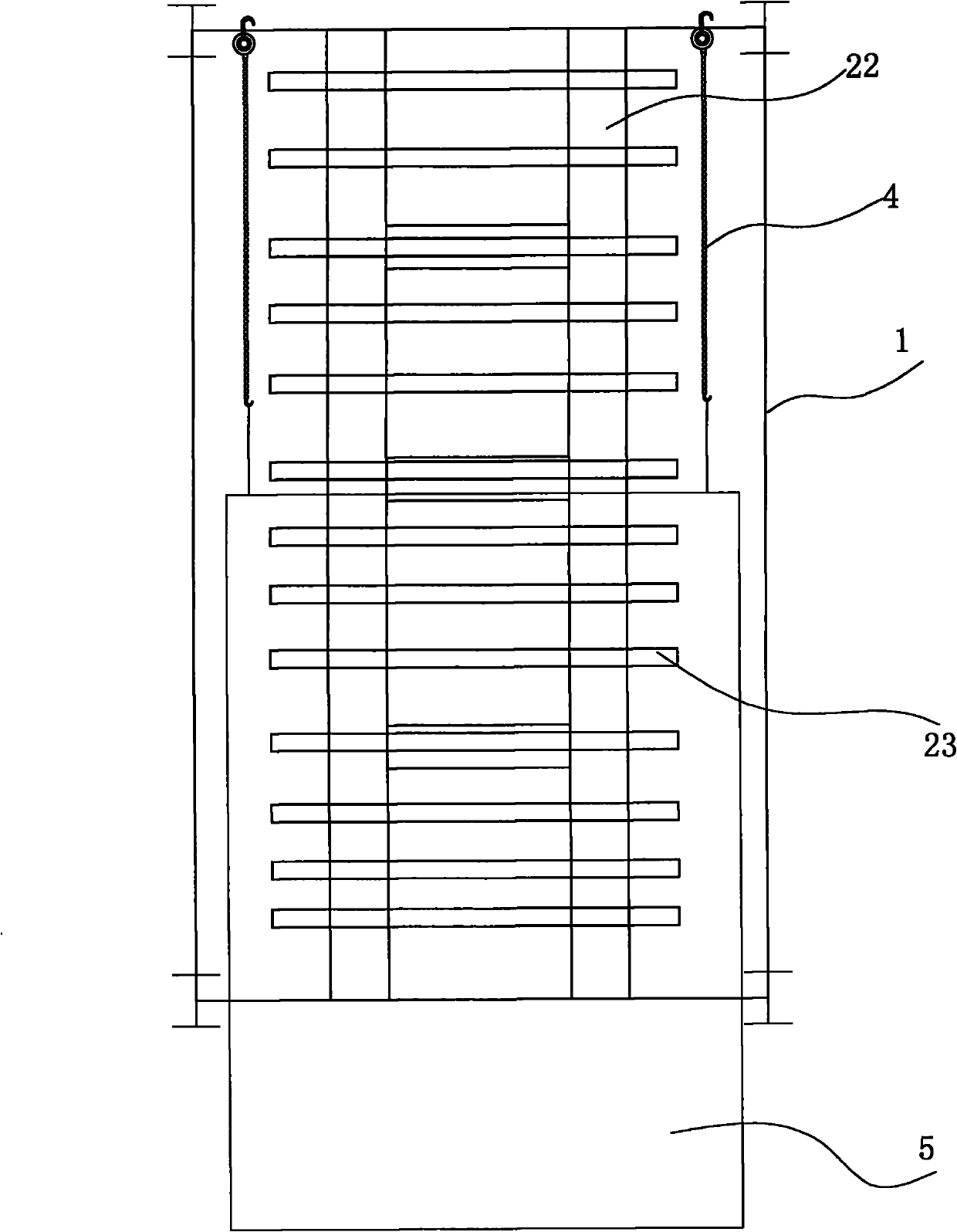

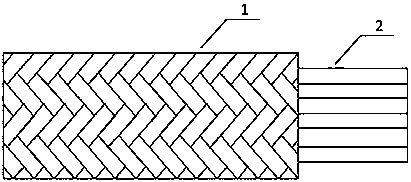

Non-bracket cable truss construction method for lifting entire body by obliquely drawing fixed jack

ActiveCN102493664AStructural tension formingSave construction periodBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a non-bracket cable truss construction method for lifting an entire body by obliquely drawing a fixed jack. The non-bracket cable truss construction method comprises the following steps of: assembling a cable bar system of a cable truss at a low-altitude position above the ground surface, and hanging the edge cable head of a bottom chord cable at the edge cable head of a top chord cable by virtue of a bottom chord connection fixture cable; mounting a fixture ear plate at the anchoring node of a peripheral structure, arranging the jack on the fixture ear plate through a hanging frame in pin joint, fixing a counter-force frame on the edge cable head of the top chord cable, and arranging a drawing fixture cable between the jack and the counter-force frame; enabling the jack to work continuously, obliquely drawing the fixture cables so that the entire cable bar system is lifted to a high altitude position; connecting the edge cable head of the top chord cable with a fixing point of the top chord cable in position; and transferring the jack, the hanging frame, the counter-force frame and the fixture cables to a bottom chord and dismounting the bottom chord connection fixture cable; tensioning the bottom chord cable until the edge cable head of the bottom chord cable and the anchoring node of the bottom chord are connected in position so that the entire cable truss is tensioned and shaped. According to the non-bracket cable truss construction method, the jack fixed at the anchoring node of the peripheral structure is used, and the entire body of the cable bar system at the low-altitude position above the ground surface is lifted by obliquely drawing the jack. Therefore, the cost and work period of erecting a bracket are saved, a fixture is lightened, and the construction efficiency is improved.

Owner:SOUTHEAST UNIV

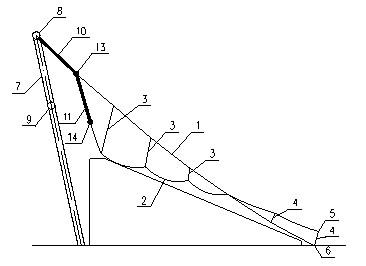

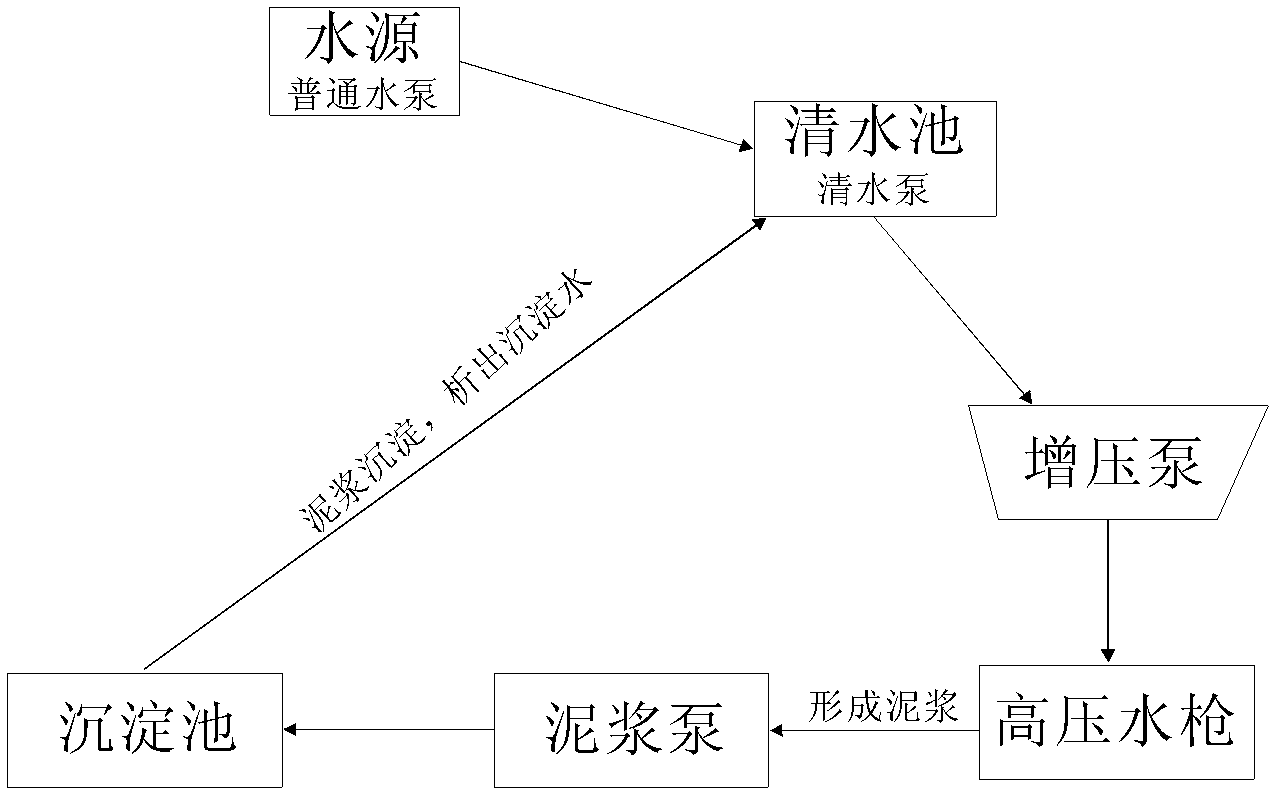

Method for excavating soil from soft soil foundation

The invention relates to a method for excavating soil from a soft soil foundation. The method includes following steps: scouring soil into slurry by high-pressure water with the pressure not lower than 0.6MPa; pumping and precipitating the slurry; conveying the slurry out of a field after the slurry is precipitated and dried or filling the slurry into the existing field; and excavating the soil. The method can well protect a building foundation and underground facilities, saves construction cost, shortens construction period, and is simple in operation, convenient in construction and low in cost.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

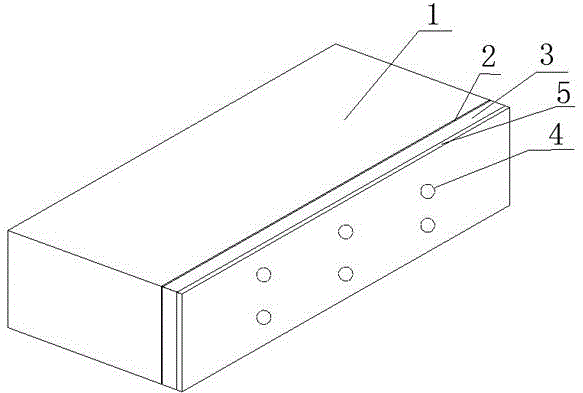

Composite insulation building blocks and production method thereof

InactiveCN105672555ALow thermal conductivityImprove thermal conductivityConstruction materialWater-setting substance layered productProduction lineBuilding energy

The invention provides composite insulation building blocks. The composite insulation building blocks are composed of autoclaved aerated concrete building blocks, bonding layers, insulation boards, anchor bolts, and bonding protective layers. The autoclaved aerated concrete building blocks, the bonding layers, and the insulation boards are connected in order through the anchor bolts, and the bonding protective layers cover the outer side. A production method employs a streamline work, is carried out according to the process, and is completed through one production line, the forming speed is fast, the waiting time is short, and the production speed is fast. The composite insulation building blocks have the advantages of reasonable design and structure, light weight, good thermal conductivity, low cost, simple construction, reasonable production process, and large output, so that high requirement of building energy saving can be satisfied.

Owner:UNIV OF JINAN

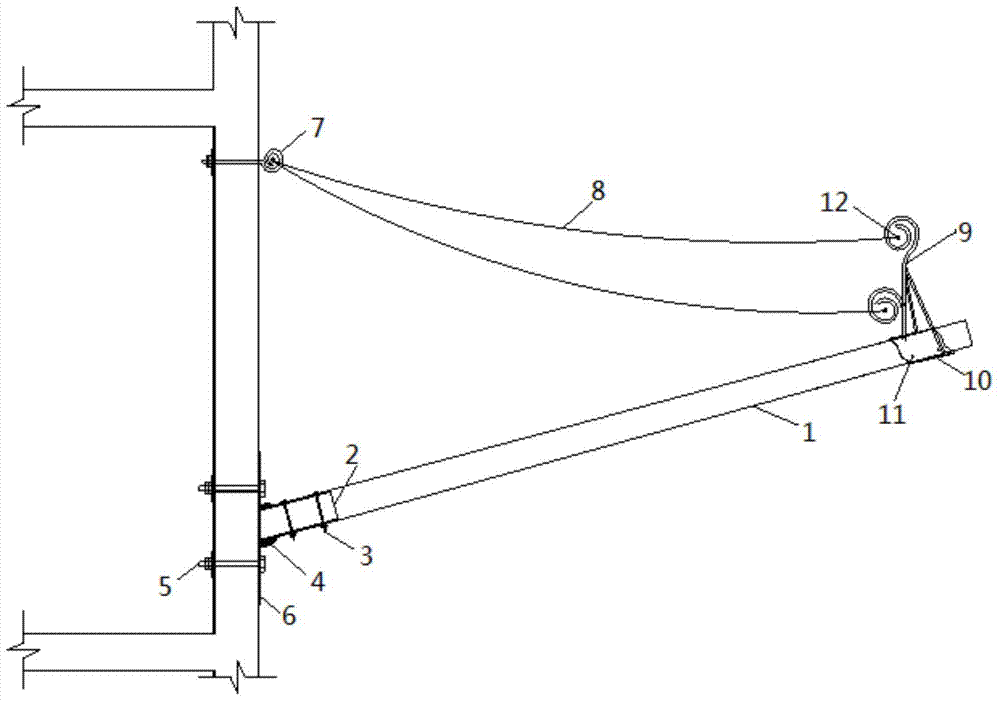

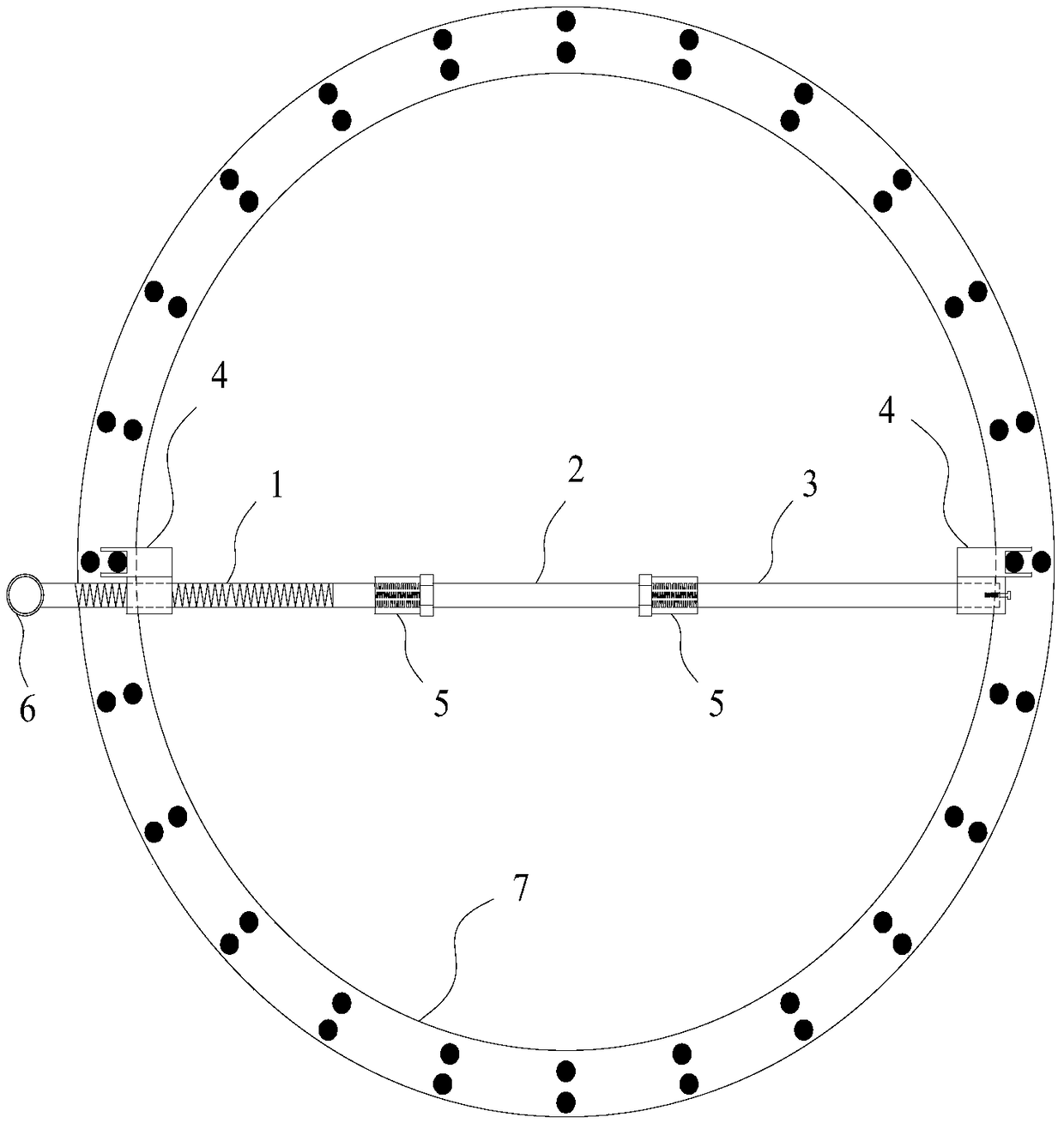

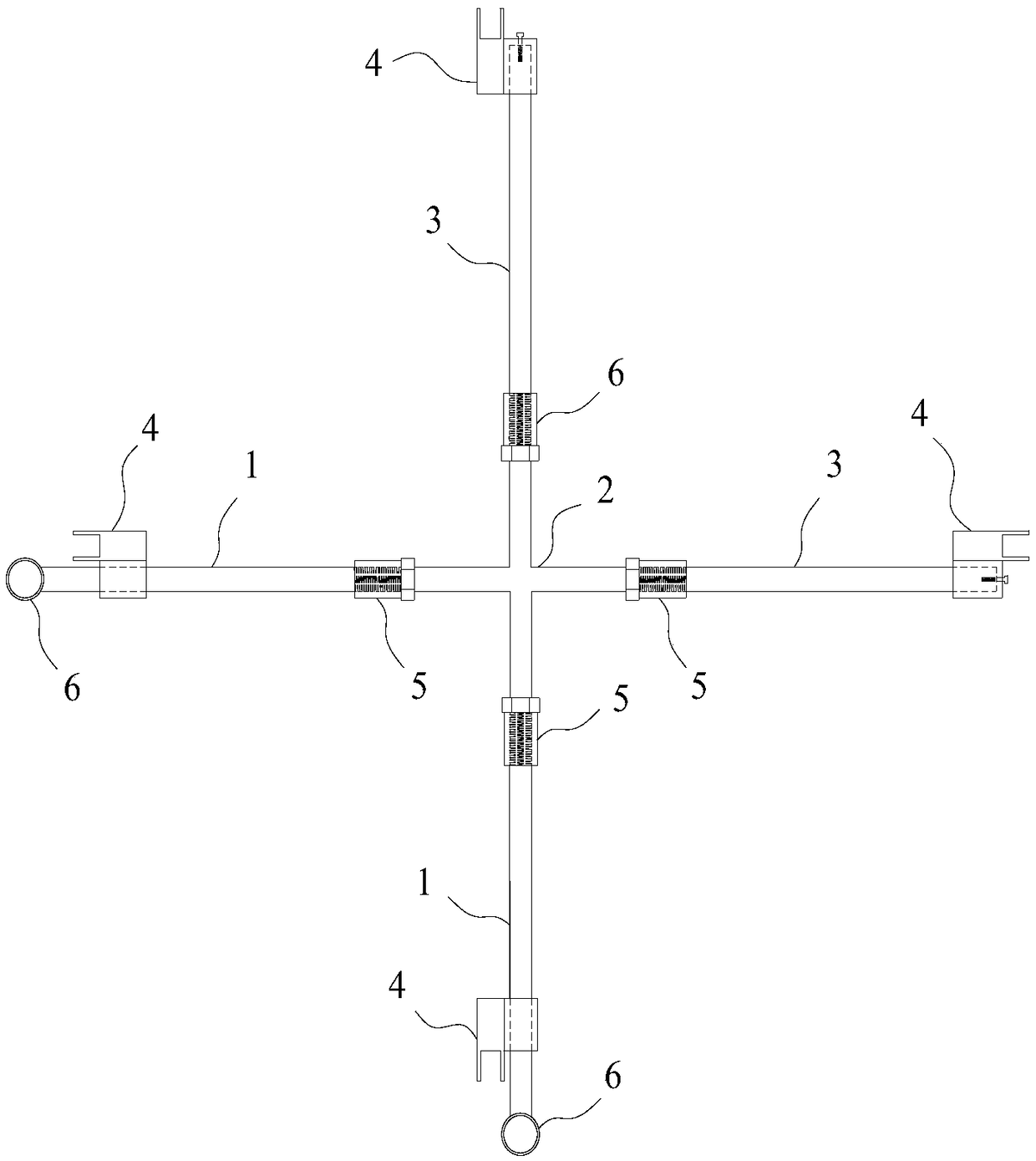

Combined-type shaping building peripheral horizontal safety net

InactiveCN103615120AConvenient up and down constructionEasy to install and disassembleBuilding material handlingSafety netArchitectural engineering

The invention discloses a combined-type shaping building peripheral horizontal safety net which comprises a plurality of net picking rods and safety nets. The net picking rods are arranged in parallel, and the safety nets are connected between the net picking rods. Crawling ladders are fixedly connected to the two sides of each net picking rod. The inner end portions of the net picking rods are connected with a fixed base. A rope penetrating support is connected to the outer end portions of the net picking rods. A steel wire rope respectively penetrates through an upper-layer embedded part and the rope penetrating support. The safety nets are connected with the steel wire rope. The fixed base is fixed to a floor board or a wall board. The combined-type shaping building peripheral horizontal safety net is safe and convenient to construct, high in efficiency, convenient to transport, rapid in assembling and disassembling, capable of greatly saving manpower and material resources and shortening the construction period, and capable of being recycled, saves materials, is remarkable in economic benefits, facilitates vertical construction by workers, and is practical, safe and reliable.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Exchanging method of exhaust-heat boiler low temperature economizer

ActiveCN102022718ASave construction periodSave construction costCranesFeed-water heatersState of artComputer module

The present invention relates to an exchanging method of an exhaust-heat boiler low temperature economizer, characterized in that the method comprises the following steps: (1) dismantling an old low temperature economizer module; (2) mounting a hoisting support, wherein the hoisting support is mounted under the low temperature economizer, and an upper end face of an upper rolling bar of the hoisting support is slightly higher than an angle iron at the lower part of the support; (3) hoisting and dragging, wherein a lifting hook of a crane is connected to partial lifting lugs on the top face of a new low temperature economizer by a sling; the new low temperature economizer is partially fed into the support from a gap at a first side face of the support; the lugs at the top face of the new low temperature economizer are connected by a chain block, and dragged along the first side to a second side face in the gap of the second side face opposite to the first side face of the support in a way of matching with the hoisting of the crane; (4) dismantling the hoisting support; compared with the prior art, in the present invention, the new low temperature economizer module can be exchanged without dismantling various modules disposed above the low temperature economizer module, so that construction period and construction cost are saved greatly; simultaneously, convenient conditions are supplied for the future operations.

Owner:CHINA PETROLEUM & CHEM CORP +2

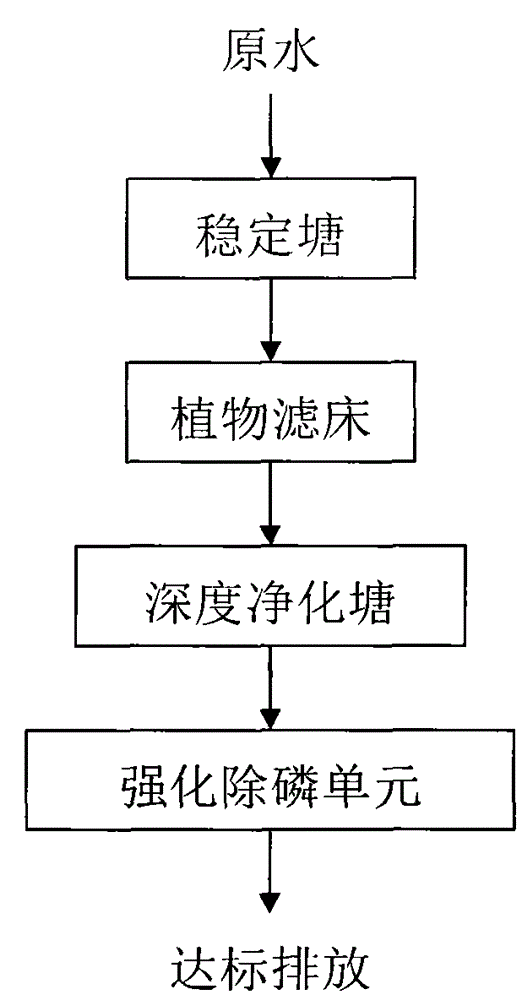

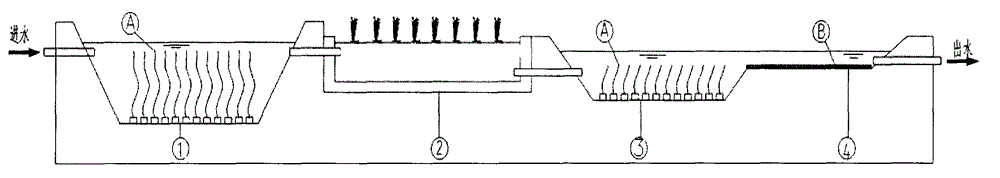

Plant filter bed ecological technology

InactiveCN106186510AReduced risk of cloggingImprove biodegradabilityMultistage water/sewage treatmentConstructed wetlandPhosphate

The invention relates to a plant filter bed ecological technology, and belongs to a wastewater treatment technique for constructed wetlands. The technology disclosed by the invention mainly comprises a stabilization pond, a plant filter bed, a deep purifying pond, and a reinforced dephosphorization unit, wherein the stabilization pond provides anaerobic environment and performs preliminary pretreatment on wastewater to remove SS, an ammonifying process is performed, and organic matters are subjected to hydrolysis acidification so as to obtain micromolecules; water flowing out of the stabilization pond enters the plant filter bed, through an aquatic plant stereoscopic net root system and biomembranes attached to the surface of the root system, the organic matters in a water body are removed, and a nitration reaction is performed; water flowing out from the plant filter bed enters the deep purifying pond; the deep purifying pond provides oxygen-deficient environment and is mainly used for converting nitrate nitrogen into nitrogen, so that decarburizing and denitriding the water body are realized; and water flowing out of the stabilization pond enters the reinforced treatment unit. A calcite filling is placed in the reinforced treatment unit, so that ions such as phosphate radicals form phosphate precipitations, and the dephosphorization effect is improved. The plant filter bed in the technology does not need the filling, so that the mounting and the operation are convenient, and the plant filter bed ecological technology is especially suitable for treatment of individually-drained wastewater in rural areas.

Owner:北京远浪潮生态建设有限公司

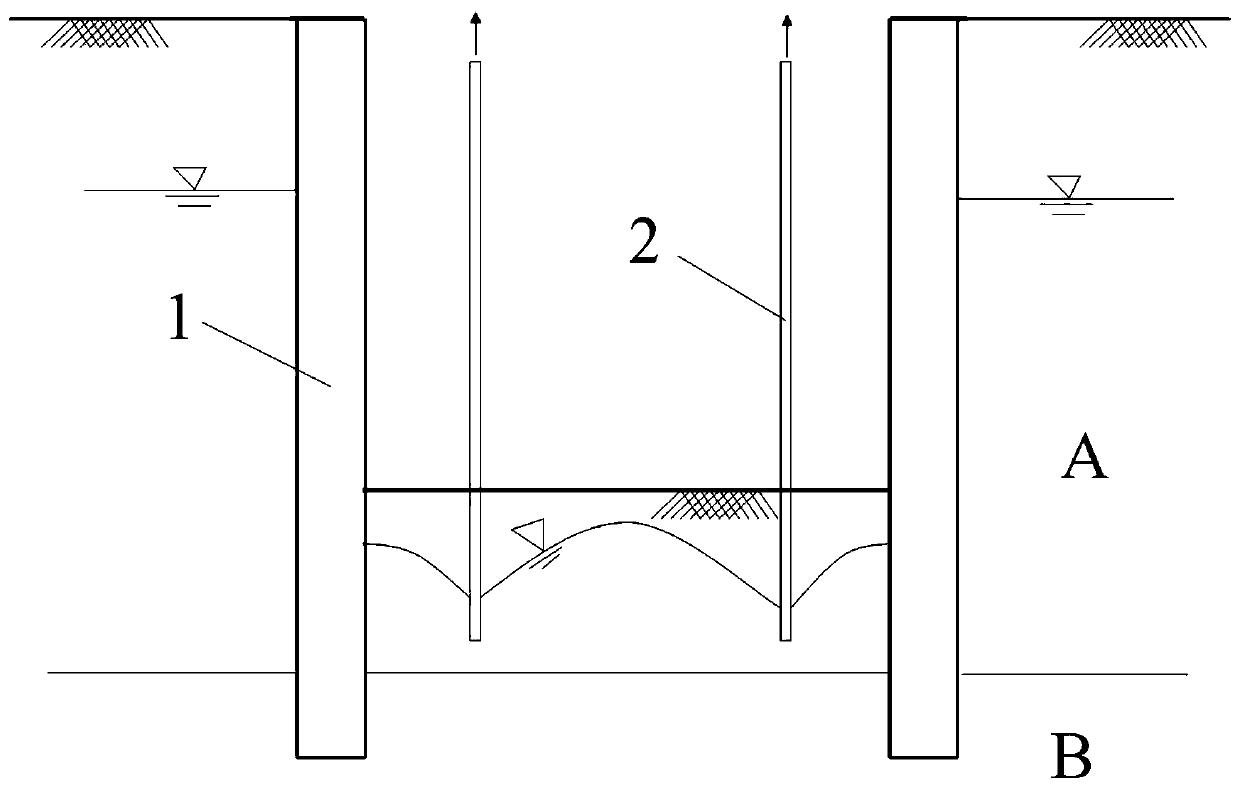

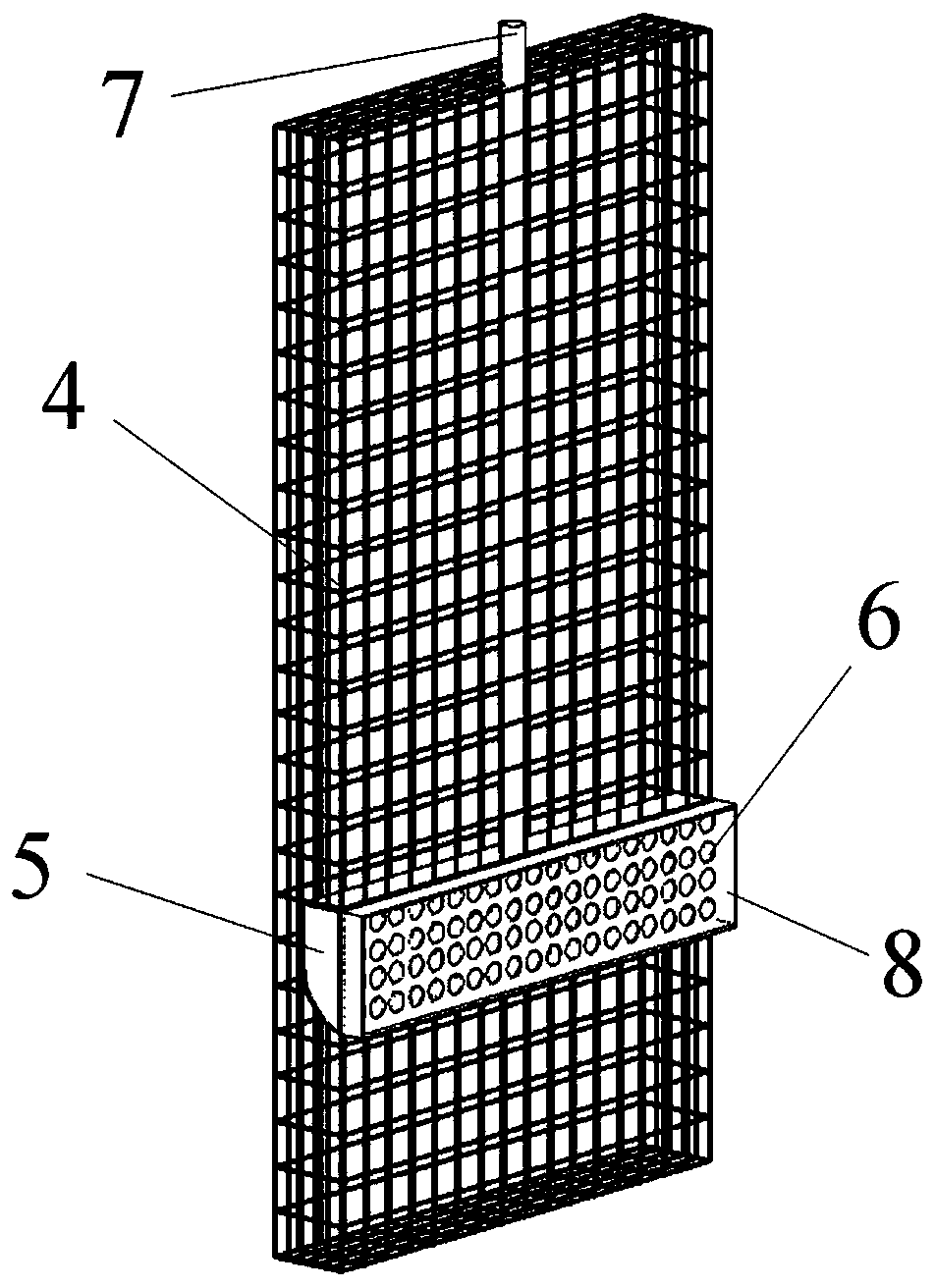

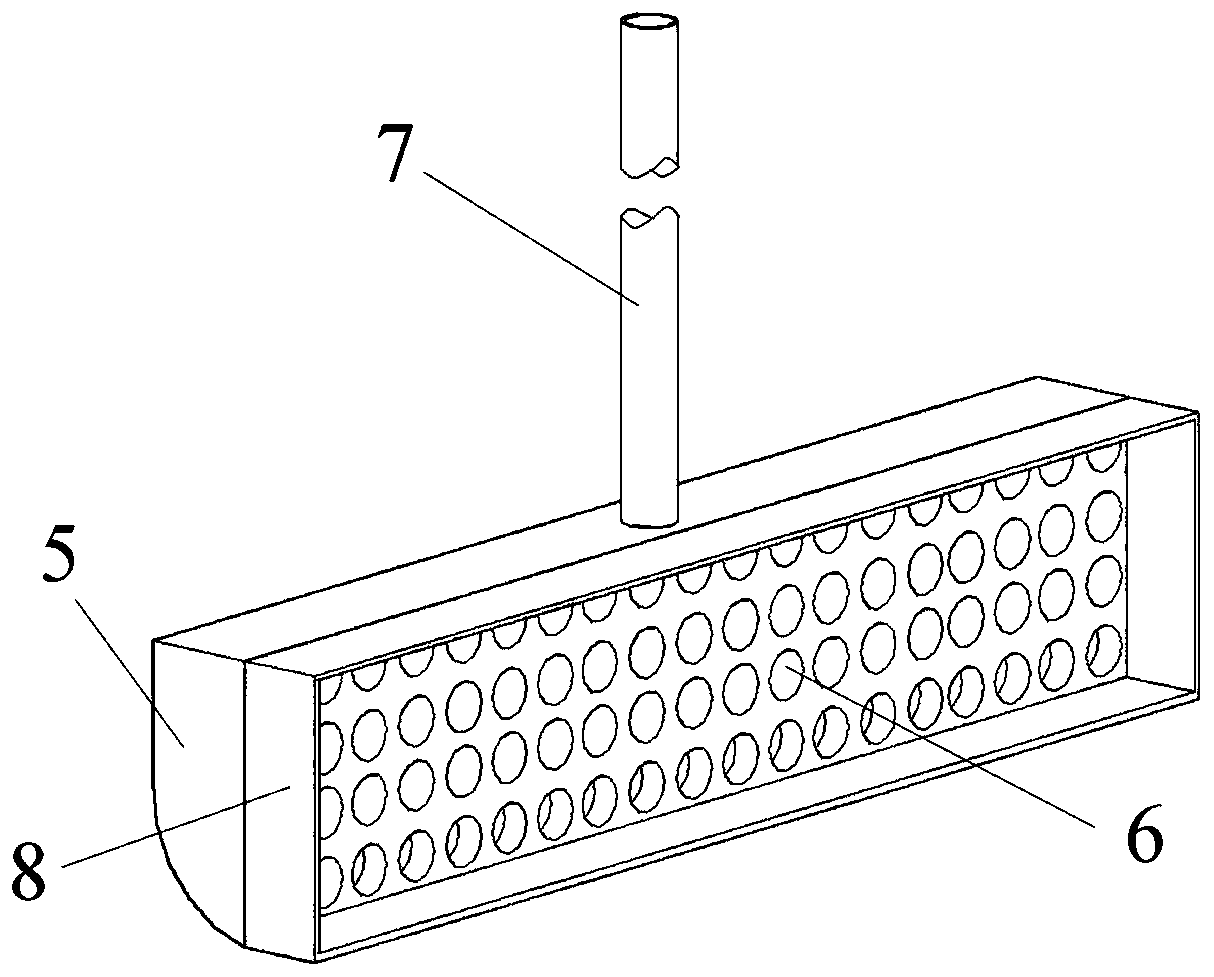

Underground diaphragm wall with pit face having water level lowering function

PendingCN110409420ASave construction periodCost savingExcavationsBulkheads/pilesSlurry wallReinforced concrete

The invention discloses an underground diaphragm wall with a pit face having the water level lowering function. The underground diaphragm wall comprises a reinforcement cage, a circular pipe and a water storage tank, wherein the circular pipe is vertically arranged and is embedded in the reinforcement cage; the top of the circular pipe stretches out of the top of the reinforcement cage; the waterstorage tank is fixed at the lower part of the pit face of the reinforcement cage and is connected with the bottom of the circular pipe; the water storage tank and the circular pipe constitute a closed communicating system; a plurality of water inlets are formed in the earth surface of the water storage tank; and the reinforcement cage is placed in a groove and forms a cast-in-place reinforced concrete wall through the concrete pouring manner. The water storage tank is prefabricated and embedded at the lower part of the pit face of the underground diaphragm wall in advance; and after construction, the water storage tank (dewatering well) can come into use, so that a traditional dewatering well does not need to be arranged on the inner side of foundation pit engineering, and the construction period and the cost of the dewatering well are greatly shortened and reduced.

Owner:CHINA COAL NO 3 CONSTR GRP

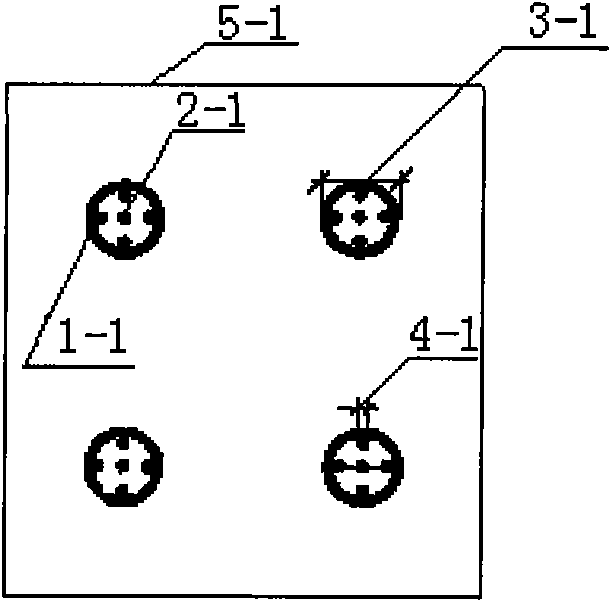

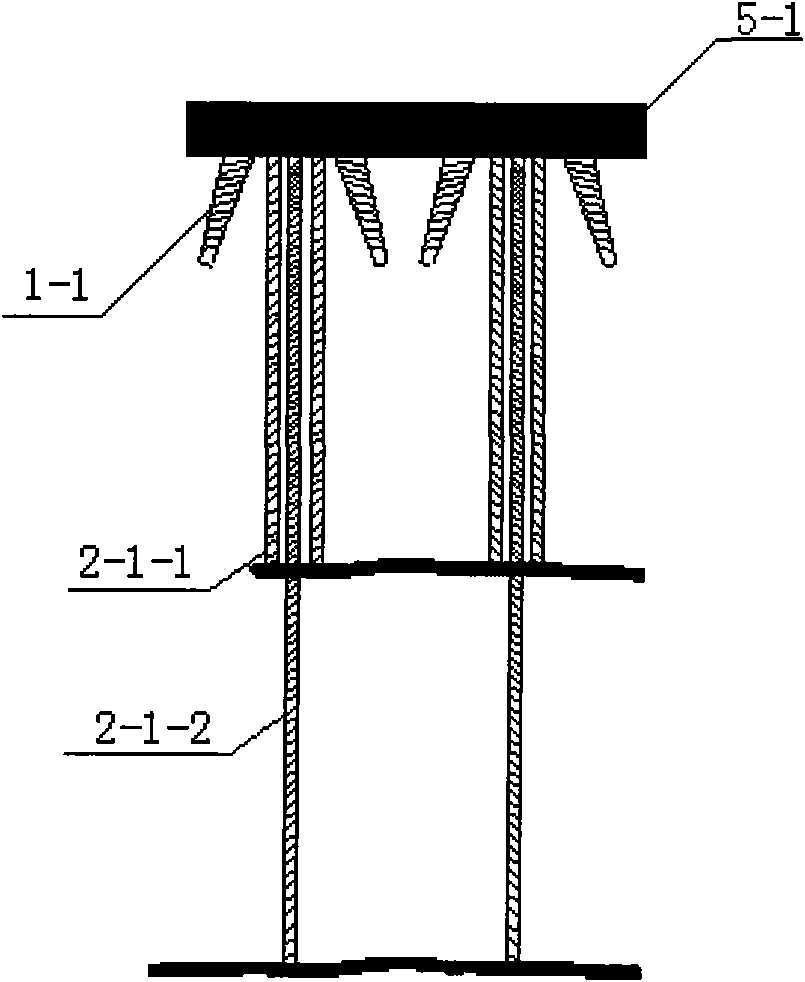

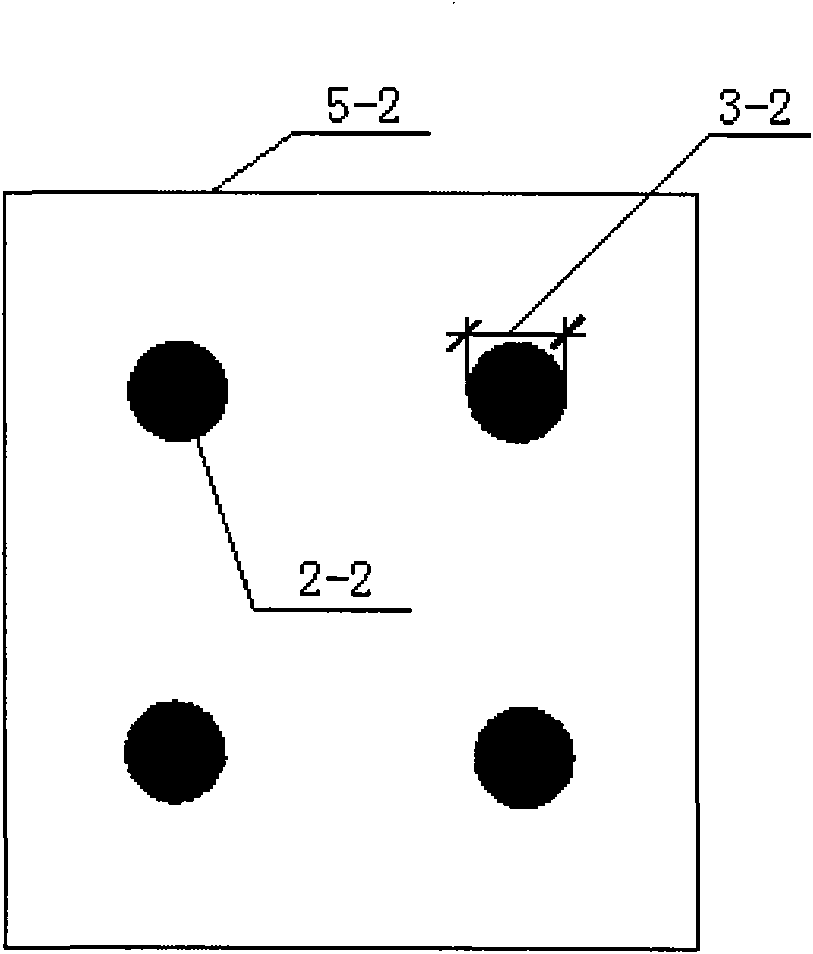

Precast perforated pipe pile and preparation method

InactiveCN101768962AImprove bearing capacityFlexible adjustment of bearing capacityBulkheads/pilesDistribution characteristicSteel tube

The invention provides a precast perforated pipe pile. A perforated pipe and concrete arranged in and out the perforated pipe form a pipe body, and the outer wall of the pipe body is provided with a self-tapping screw which is a spiral bump arranged on the outer wall of the pipe body. The bottom end of the pipe body is a flat head or a tip head, and the top end of the pipe body is a multi-face column and is externally sheathed with a side limited ring. The side limited ring is in a horn shape, and foundation soil is arranged between the pipe body and the side limited ring. The preparation method of the precast perforated pipe pile comprises the following steps: the perforated pipe is manufactured by steel pipes with different specifications, and the thickness is larger than 2 mm; the aperture of perforated holes in the perforated pipe is manufactured by a cutting mode and is determined according to the grain diameter of stone in the concrete, and the distribution of the perforated holes from the pile top to the pile end is determined according to the distribution characteristics of additional stress of the pile; the spiral bump of the outer pipe of the perforated pipe is determined according to the bearing capacity of single pile and the rotational torque; and a variety of parameters of the perforated pipe precast pile are determined according to shared building load, final foundation deformation, foundation soil conditions and conditions for affecting pile sinking.

Owner:吴保全

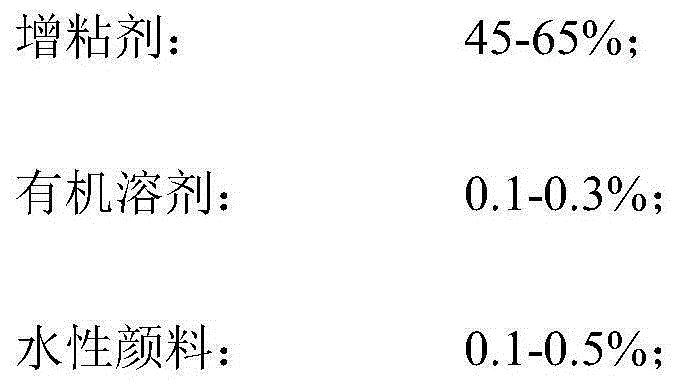

Water-based tile adhesive and preparation method and construction method thereof

InactiveCN105176451AEasy to prepareImprove adhesionCovering/liningsEster polymer adhesivesWater basedOrganic solvent

The invention discloses a water-based tile adhesive. The water-based tile adhesive is prepared from, by weight, 45%-65% of tackifier, 0.1%-0.3% of organic solvent, 0.1%-0.5% of water-based pigment and the balance water. The preparation method of the adhesive comprises the steps that 1, the tackifier and the organic solvent are stirred and mixed evenly at the rotation speed ranging from 1000 rpm to 3000 rpm and at the temperature ranging from 60 DEG C to 100 DEG C to form a mixed component A; 2, the water-based pigment and the water are stirred and mixed evenly at the room temperature to form the mixed component B; 3, the mixed component A in the first step and the mixed component B in the second step are stirred and mixed evenly at the rotation speed ranging from 2000 rpm to 4000 rpm and at the temperature ranging from 40 DEG C to 60 DGE C, and the water-based tile adhesive is obtained. The construction method comprises the steps that the adhesive is evenly brushed on the back surface of a tile, and when the adhesive is solidified to be in a semi-transparent state, the tile is attached to the surface to be attached through cement mortar. The preparation method of the water-based tile adhesive is simple, the construction technology is simple and convenient, the adhesive force is strong, and the problem that when tiles, marble and the like are attached to the wall, empty drum and disengagement are prone to occurrence can be effectively solved.

Owner:邓永忠

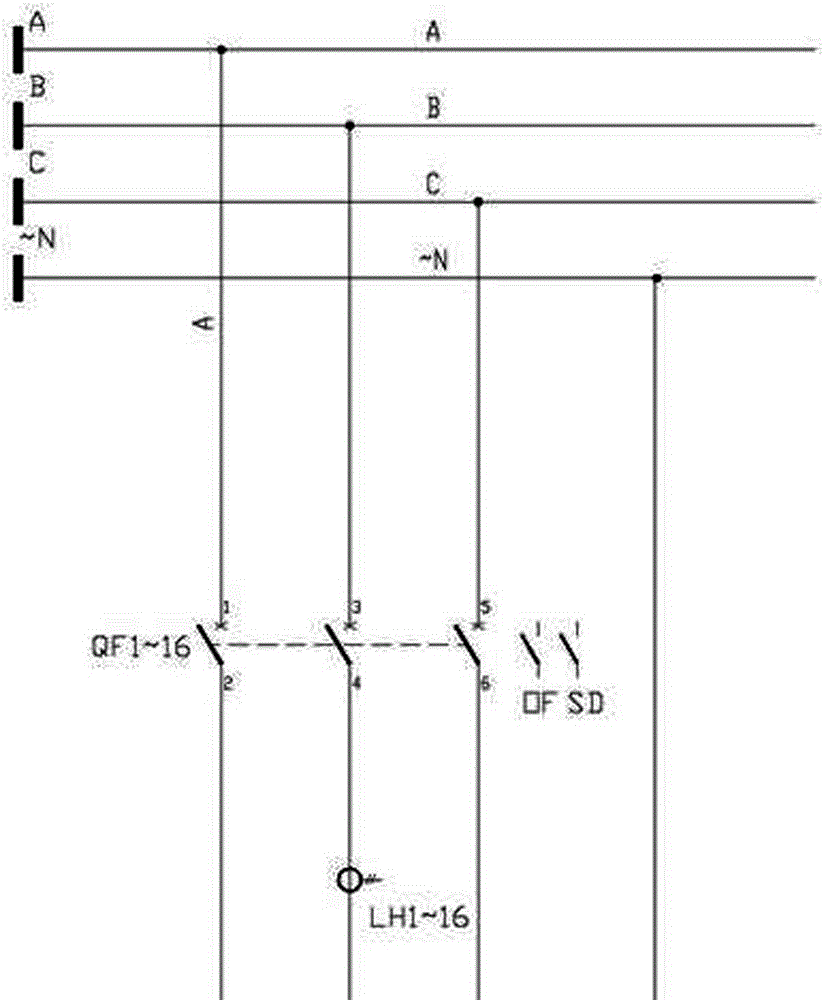

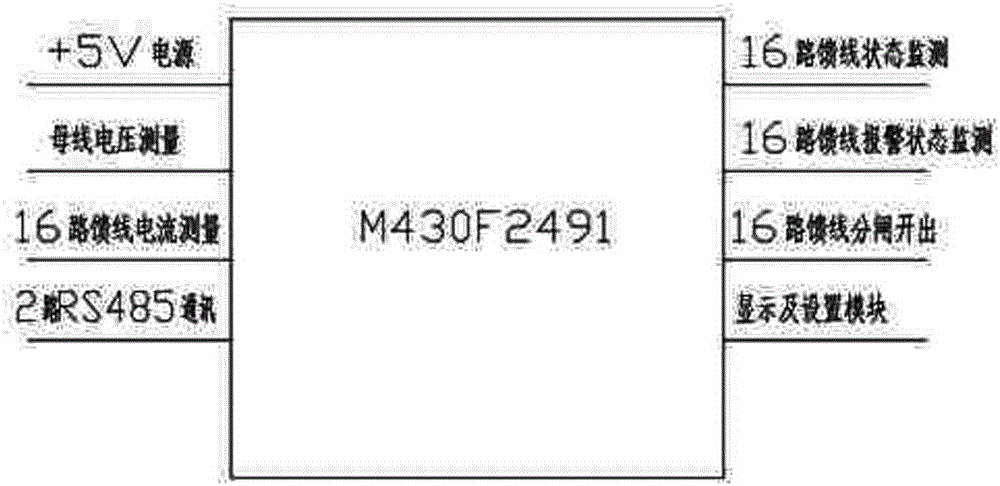

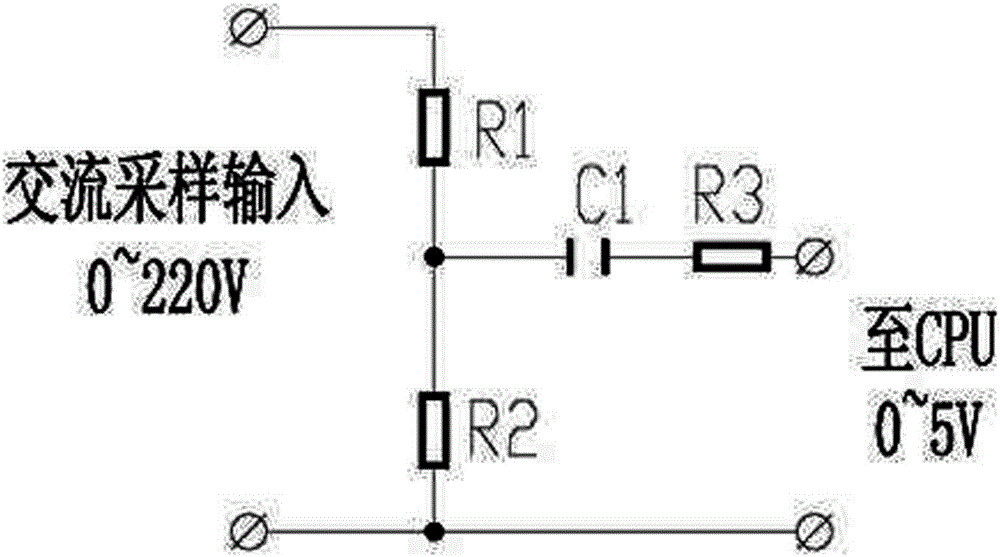

Low-voltage switchgear feeder monitoring and measuring device

ActiveCN105223404ALow costSimple feeder monitoringProgramme controlComputer controlMicrocontrollerMeasurement device

The invention relates to the field of alternating-current power source monitoring and measuring, and especially relates to a low-voltage switchgear feeder monitoring and measuring device. The device has functions like feeder switching status, feeder alarm tripping status, feeder current measurement, bus voltage measurement, feeder control output and communication. The device is installed on a low-voltage switchgear feeder screen to achieve a four-remote control function, and can be conveniently connected to an integrated automation system. The low-voltage switchgear feeder monitoring and measuring device adopts an M430F2491 embedded microcontroller controller as a core processor to monitor feeder switching status, feeder alarm tripping status, feeder current measurement, bus voltage measurement, feeder control output, communication and the like; the device integrates the functions of multiple pieces of original feeder measuring and monitoring equipment, and therefore, low-voltage switchgear feeder monitoring is more concise, and the level of automation is improved; and the device is integrated with the function of communication, so that operators can easily monitor the power and status of a low-voltage switchgear feeder and remotely control the tripping of a feeder branch.

Owner:广东正诚电气科技有限公司

Height addition construction method for wood-and-steel template

InactiveCN102367703ASimple processReasonable workmanshipForms/shuttering/falseworksBuilding material handlingCounter-pullEngineering

The invention discloses a height addition construction method for a wood-and-steel template, which relates to the technical field of construction engineering, in particular to a wall surface pouring construction technology. The method comprises the following steps of: arranging a small wood beam at the upper end of a large lower section template; arranging a large vertical wood beam on the back face of an upper section template; arranging another small wood beam at the lower end of the large wood beam; fixedly connecting the two small wood beams through a bolt; positioning the inner side face of the large lower section template and the inner surface of the upper section template on the same plane; fixing the large wood beam through a counter-pulling bolt; and pouring. The method has a simple and reasonable process, and is convenient for construct; and labor force and construction period are saved, slurry leakage and seams on a upper section wall surface and a lower section wall surface are prevented, most importantly, slab staggering on a high wall surface can be prevented, later decoration is facilitated, and the engineering quality is improved.

Owner:JIANGSU JIANGDU CONSTR GRP

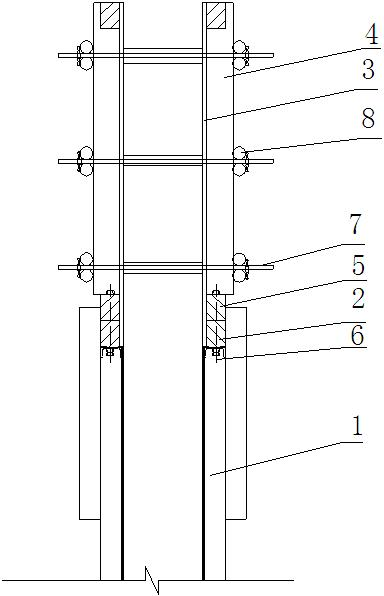

Method and device for treating and recycling mine wastewater by using purified diatomite

InactiveCN106830468ASimple processEasy to operateWaste water treatment from quariesWater/sewage treatment by irradiationAutomatic controlWater quality

The invention relates to a method for treating and recycling mine wastewater by using purified diatomite; the method comprises the following steps: firstly, the mine wastewater is collected via a water absorbing tank firstly, then the wastewater is evenly stirred by a stirrer, next the wastewater is lifted to a purified diatomite reactor by a submersible sewage pump, at the same time, purified diatomite is added to the wastewater before the submersible sewage pump, and the wastewater and the purified diatomite achieves full contact, adsorption and polymerization through intense stirring of the pump in the lifting process; and in the purified diatomite reactor, suspended matters, oil pollutants, a part of COD and metal ions in the wastewater are subjected to reaction and are evenly mixed for adsorption and polymerization, then the treated wastewater is classified and is subjected to mud water separation in the purified diatomite reactor, and water in a gutter groove is disinfected by ultraviolet rays and then reaches the water quality standard of urban miscellaneous water. The method can realize full-automatic control, has simple process flow, and realizes unmanned management. The method can reuse the resources and realize the purposes of high efficiency, energy saving and resource regeneration.

Owner:郭晓辉

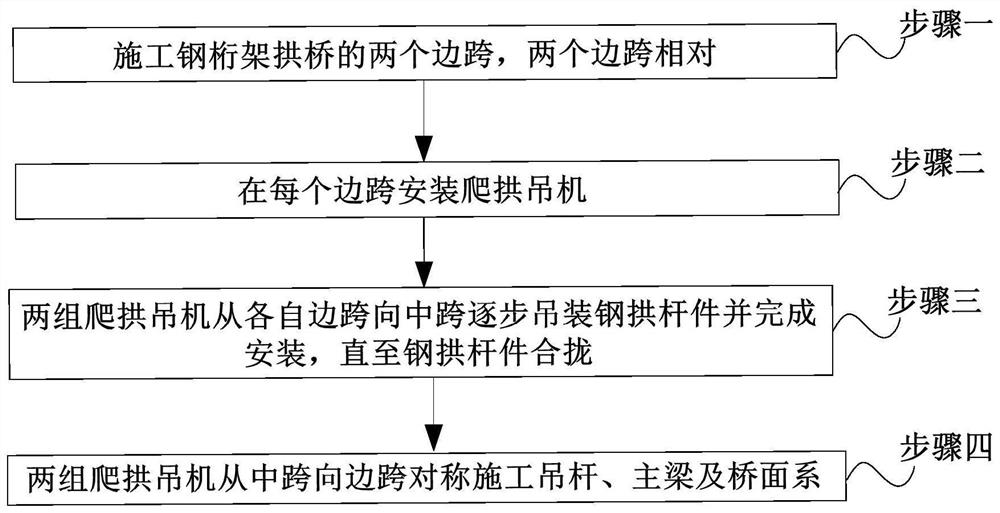

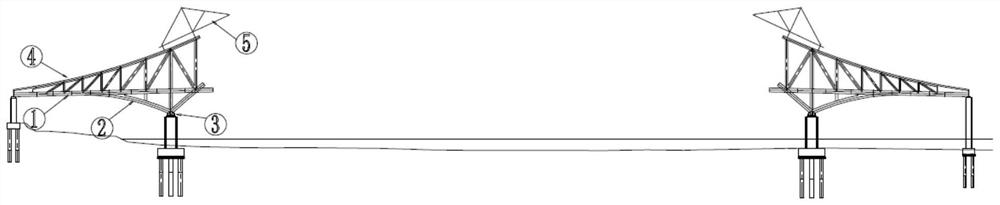

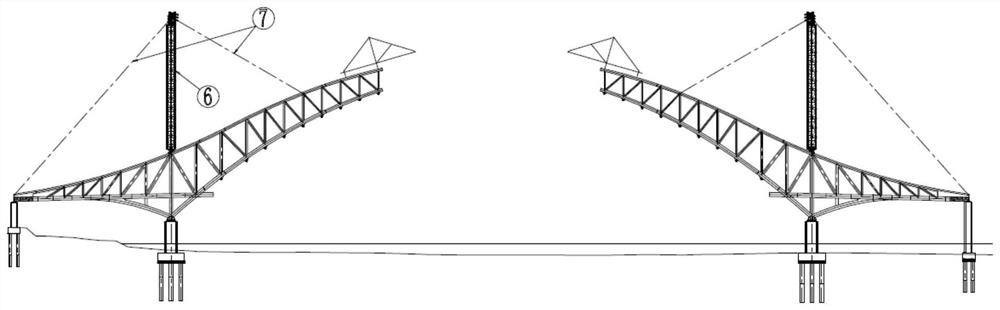

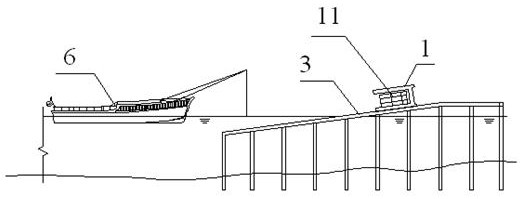

Steel truss arch bridge arch rib and main beam mounting method

PendingCN113502743AAchieve installationSave construction equipmentBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention provides a steel truss arch bridge arch rib and main beam mounting method, relates to the technical field of bridge construction, and aims to realize mounting of an arch rib and a main beam at the same time and save the construction period and construction equipment. The method comprises the following steps that firstly, two side spans of the steel truss arch bridge are constructed, and the two side spans are symmetrically constructed; secondly, an arch climbing crane is installed on each side span; thirdly, the two sets of arch climbing cranes gradually hoist the steel arch rod pieces from the side spans to the middle spans of the two sets of arch climbing cranes, and installation is completed till the steel arch rod pieces are folded; and fourthly, the two sets of arch climbing cranes symmetrically construct suspenders and main beams from the middle span to the side spans. According to the method of the invention, the arch rib and the main beam can be simultaneously mounted by adopting the arch climbing crane, so that one machine has two purposes, construction equipment is saved, and the construction period is shortened.

Owner:NO 2 ENG CO LTD OF CCCC THIRD HARBOR ENG CO LTD +1

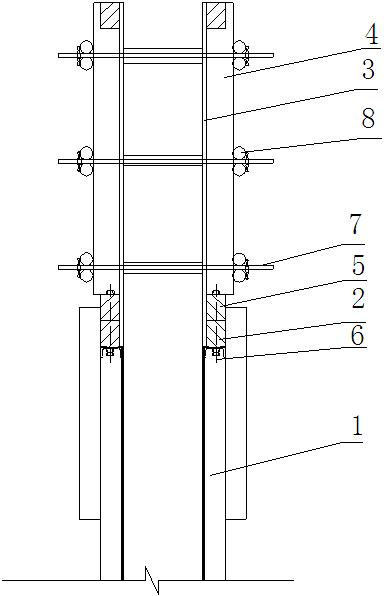

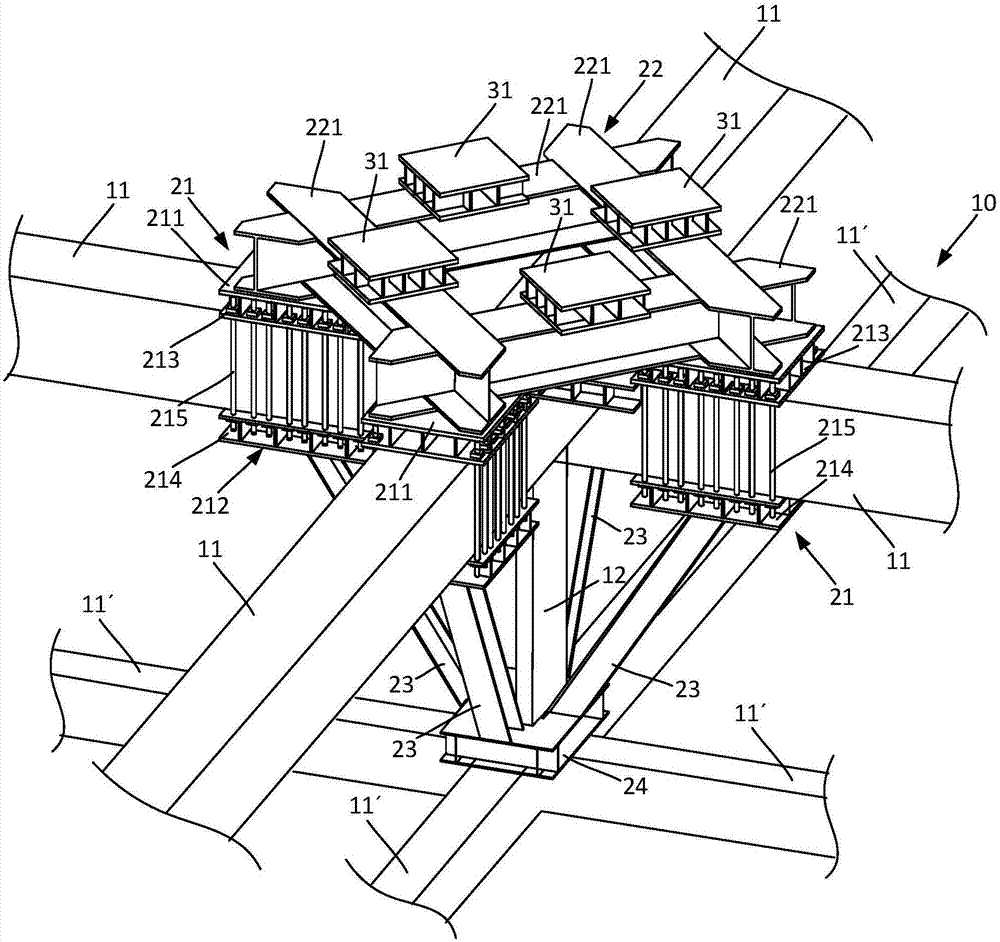

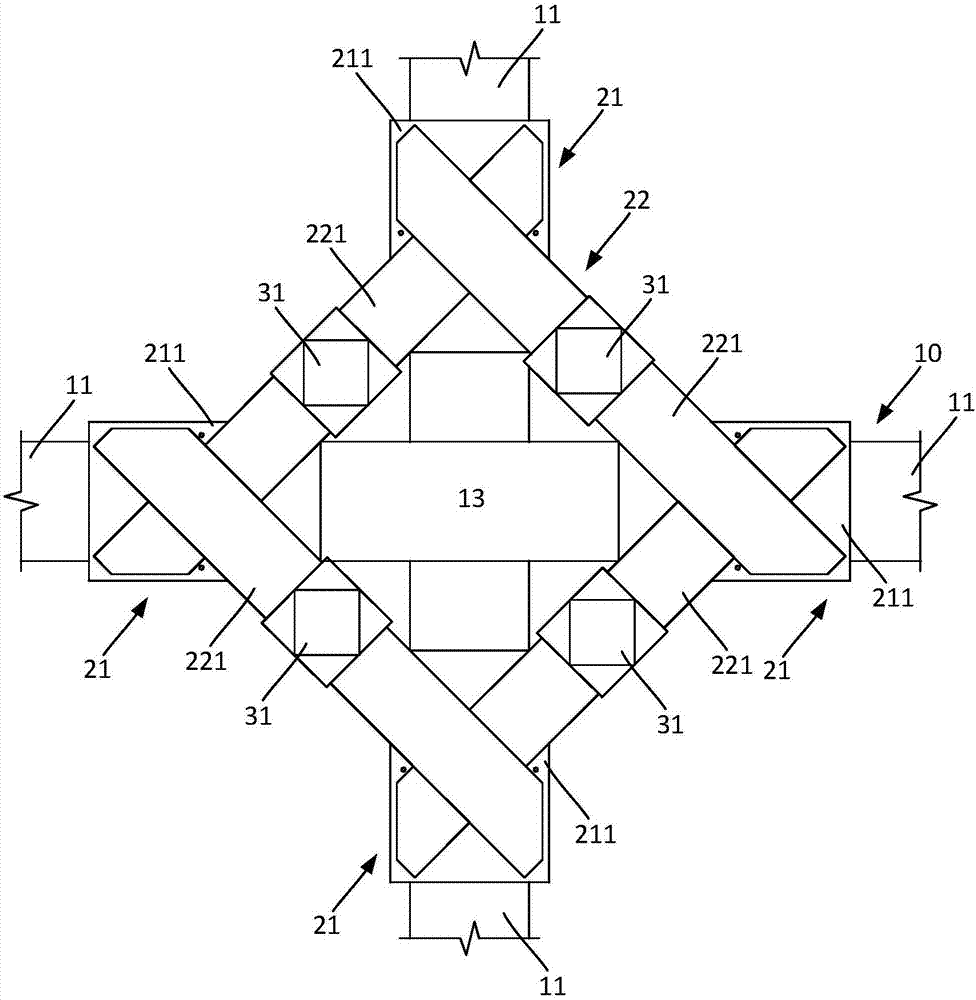

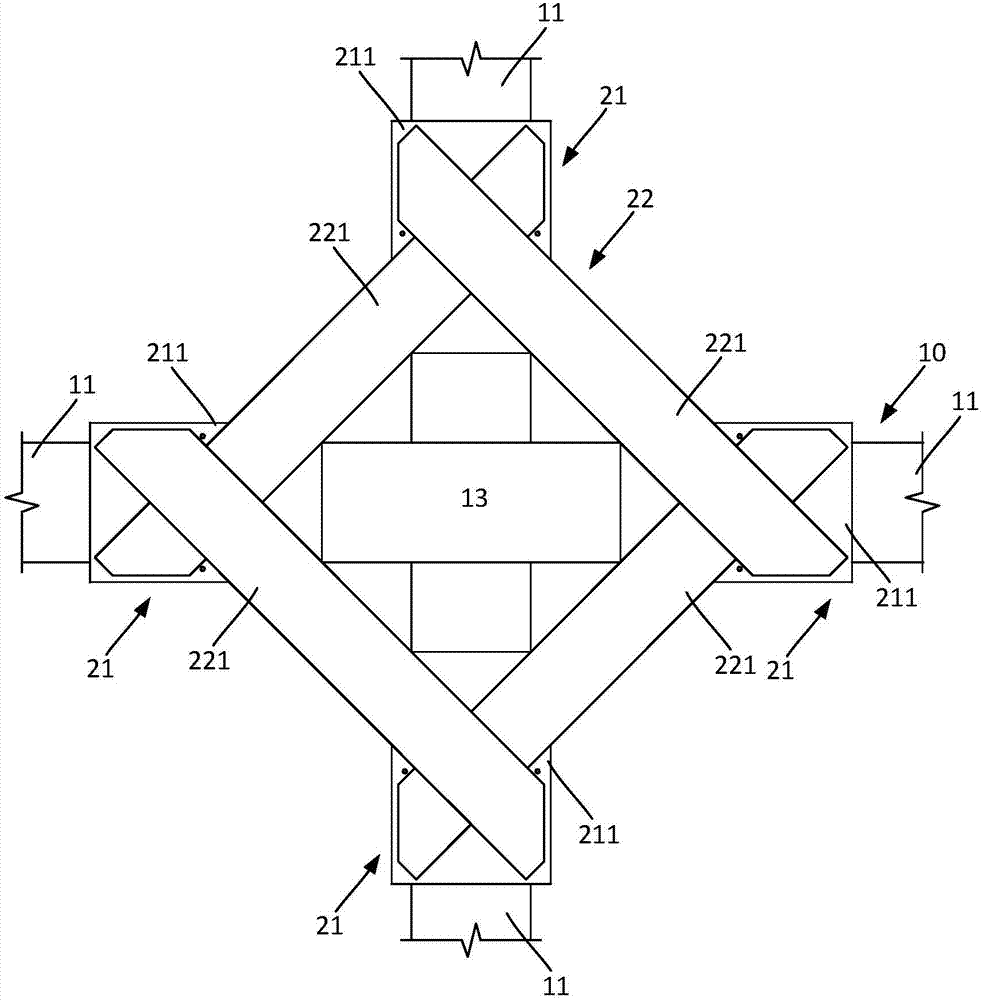

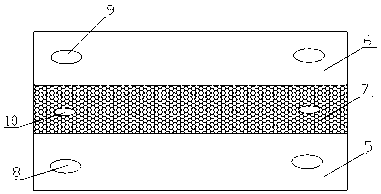

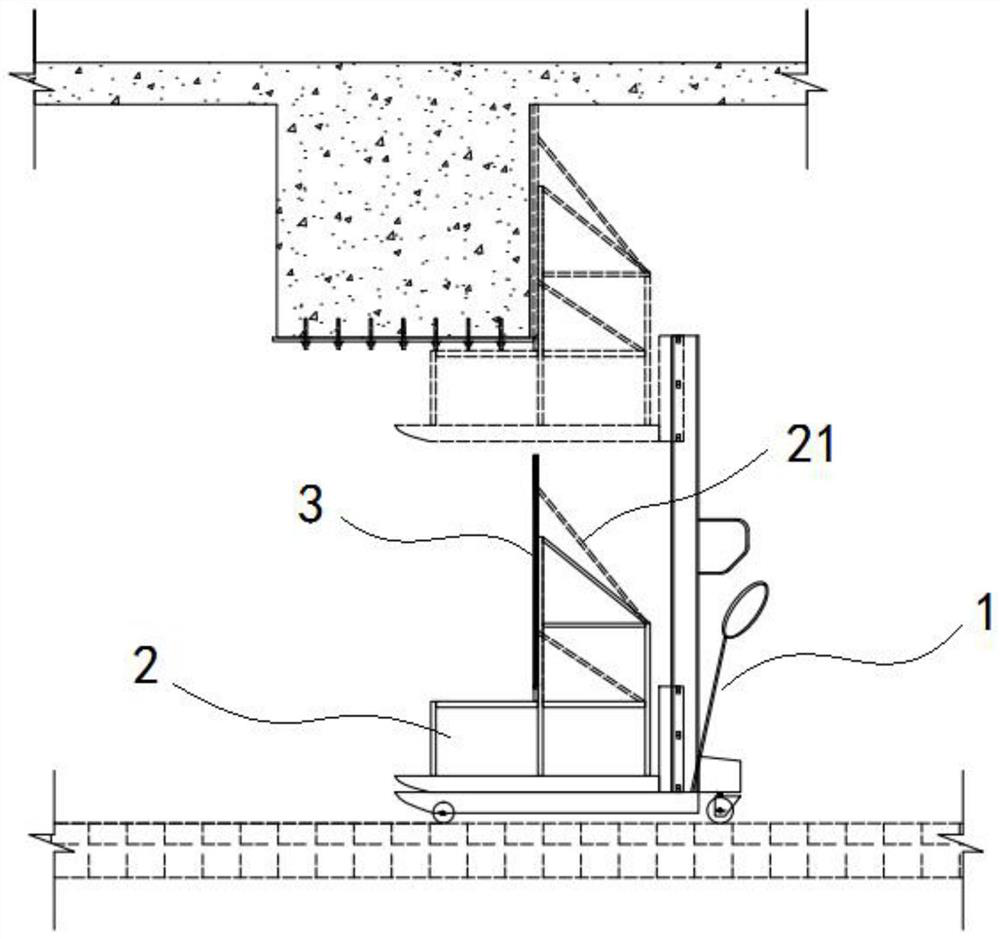

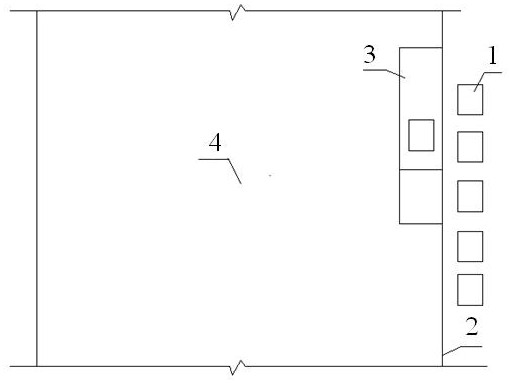

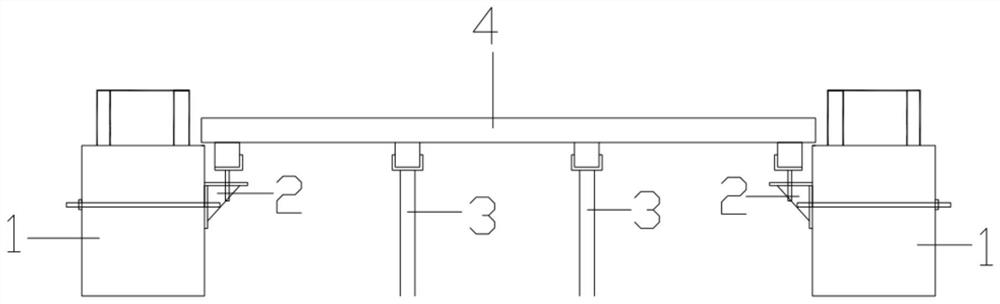

Girder embracing type tower crane foundation steel bearing table and construction method thereof

ActiveCN107419740AStable supportStable overturning forceFoundation engineeringFloor slabArchitectural engineering

The invention relates to a girder embracing type tower crane foundation steel bearing table and a construction method thereof. The steel bearing table comprises girder embracing structures and a foundation steel bearing table body, wherein the girder embracing structures are mounted on frame girders of an existing structure and are close to a girder-column joint of the frame girders and a frame column; the girder embracing structures penetrate through the portions, on the two sides of the frame girders, of a floor slab and are clamped and fixed to the frame girders; mounting surfaces are formed on the girder embracing structures and located on the tops of the frame girders; and the foundation steel bearing table body is fixedly mounted on the mounting surfaces. The girder embracing structures are mounted on the frame girders, the foundation steel bearing table body is borne through the girder embracing structures, the girder embracing structures and the frame girders are embraced together to form a whole sable stress body, the anti-pulling effect of the connection positions of the foundation steel bearing table body and the girder embracing structures can be improved, the girder embracing structures and the frame girders form the whole stress body, the overturning force of a tower crane can be effectively resisted, the supporting stability of the foundation steel bearing table body is guaranteed, and the using safety of the tower crane is ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

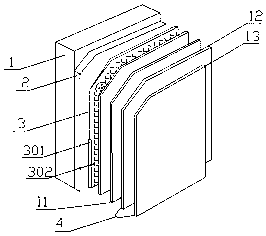

Building thermal insulation wall

PendingCN107620399AOvercome the drumOvercome water seepageConstruction materialWallsBrickThermal insulation

The invention relates to the technical field of wall thermal insulation, in particular to a building thermal insulation wall. The building thermal insulation wall comprises a foundation wall, a mortarleveling layer, a thermal insulation layer, a crack resistant protective layer and a facing layer. The foundation wall is built by laying a plurality of composite type thermal insulation bricks by adopting a wall-building binding agent, each composite type thermal insulation brick comprises a first brick body, a second brick body and a thermal insulation body, and the first brick body and the second brick body are cuboid bricks with the same size; and the thermal insulation body is a cuboid thermal insulation plate arranged between the first brick body and the second brick body in a clamped mode, the two wide side faces of the thermal insulation body are in contact with one wide side faces of the first brick body and the second brick body correspondingly, the areas of the two wide side faces of the thermal insulation body are the same as the areas of the wide side faces of the first brick body and the second brick body, and therefore the first brick body, the thermal insulation body and the second brick body form a cuboid brick blank. According to the building thermal insulation wall, the living comfort degree is increased, because brick bodies on the two sides adopt inorganic building materials, the fireproof effect is excellent, if the thermal insulation body adopts a fireproof type material, the fireproof effect is better, and fire hazards can be effectively and completelyeradicated.

Owner:湖州交科规划设计有限公司

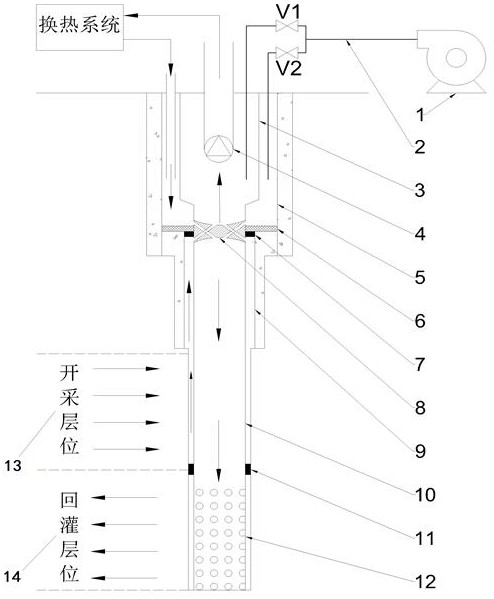

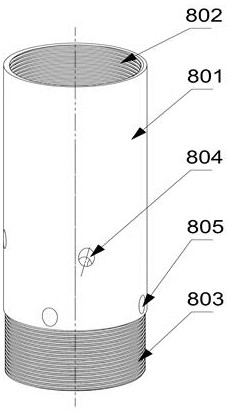

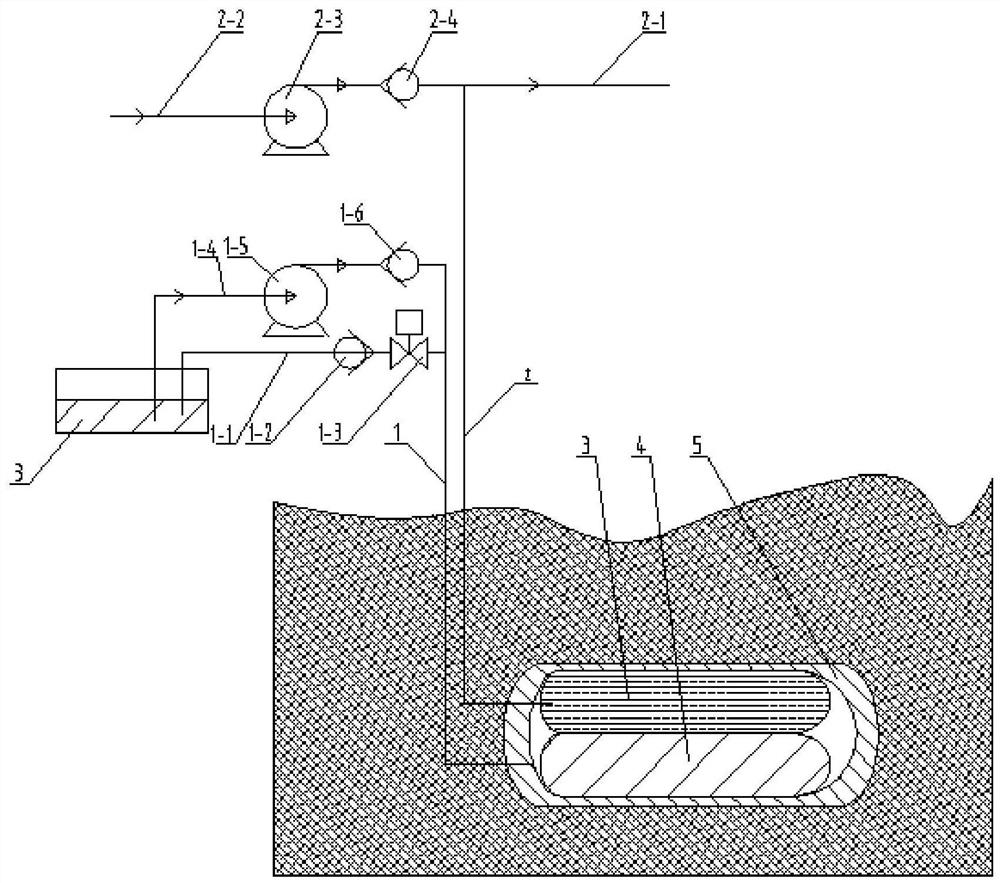

Same-well mining and irrigating device for medium-deep geothermal well and operation method thereof

ActiveCN112240177ALow head requirementLow costGeothermal energy generationFluid removalThermodynamicsMechanical engineering

The invention relates to the technical field of geothermal exploitation, in particular to a same-well mining and irrigating device for a medium-deep geothermal well and an operation method thereof. Asurface casing inner diameter middle-downward drilling placement technology casing fixing method, and a technology casing inner diameter middle-downward drilling placement production solid pipe fixingmethod are adopted; and a tubular column structure of a production screen pipe is arranged at the bottom of a production solid pipe. The same-well mining and irrigating device for the medium-deep geothermal well is simpler and more reliable; and if an exploitation layer and a recharge layer need to be switched, a pipe column does not need to be pulled out, and only the replacement assembly in a geothermal water converter needs to be replaced, so that the construction period is shortened, and the maintenance cost is reduced.

Owner:HEBEI GREEN ENERGY GEOTHERMAL DEV CO LTD

Construction method of semi-sunken self-balancing fusiform double-arch fabricated overpass

PendingCN114086440AWill not affect trafficEasy and quick passRoadwaysBridge erection/assemblyMortise and tenonArchitectural engineering

The invention discloses a construction method of a semi-sunken self-balancing fusiform double-arch fabricated overpass, which belongs to the technical field of roads and bridges, and is arranged at a crossroad. The method comprises the following steps that A, site preparation is performed; B, the lower arch prefabricated parts are hoisted to the designated position, and then the lower arch prefabricated parts are connected to form a second arch bridge; C, the supporting column is hoisted to the designated position and connected with the lower arch prefabricated part; and D, the upper arch prefabricated part is hoisted to a designated position, then the upper arch prefabricated part is connected with the supporting columns to form a first arch bridge, and the prefabricated parts at the two ends of the first arch bridge and the second arch bridge are connected through mortise and tenon joint structures. By adopting a double-arch form, passing of vehicles and pedestrians in all directions cannot be affected at the crossroad, an existing traffic light system can be omitted, and rapid passing of the vehicles and the pedestrians is achieved; and the second arch bridge is a sunken structure, the first arch bridge can be prevented from being too high, the bridge floor is prefabricated in a factory and installed on site, and rapid construction can be achieved.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

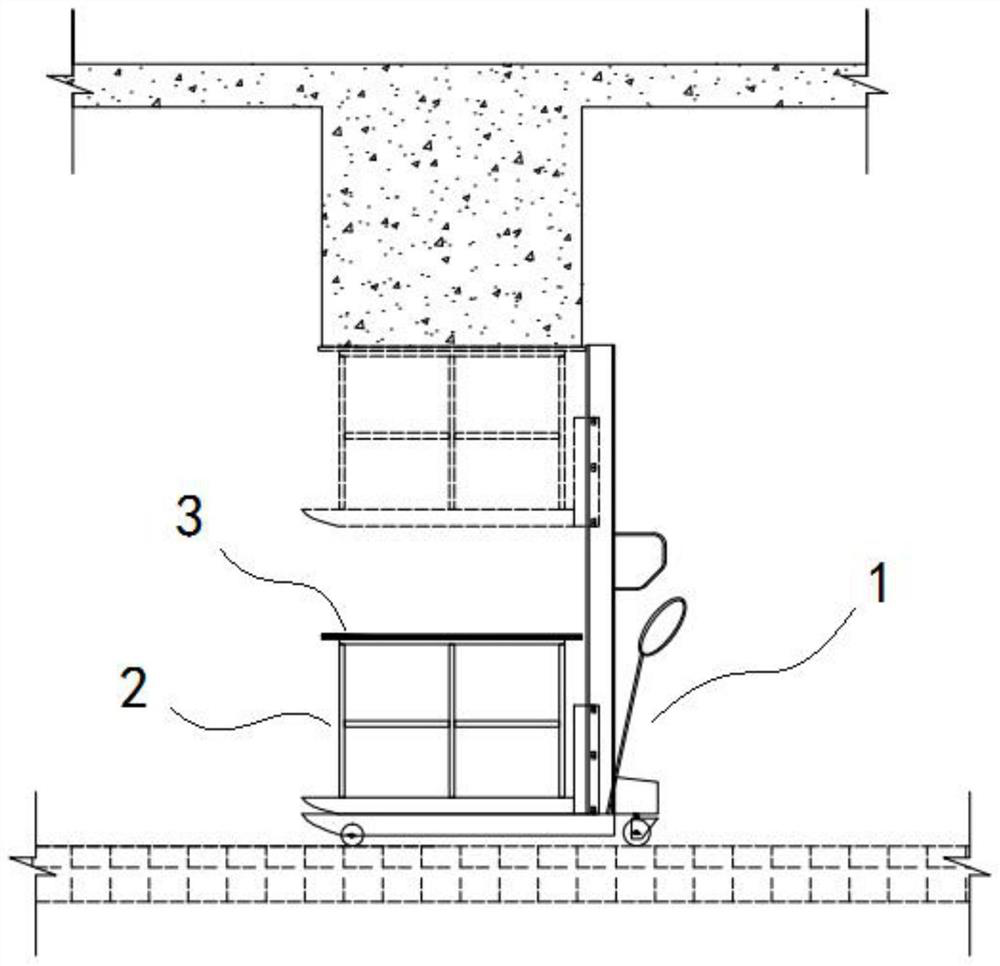

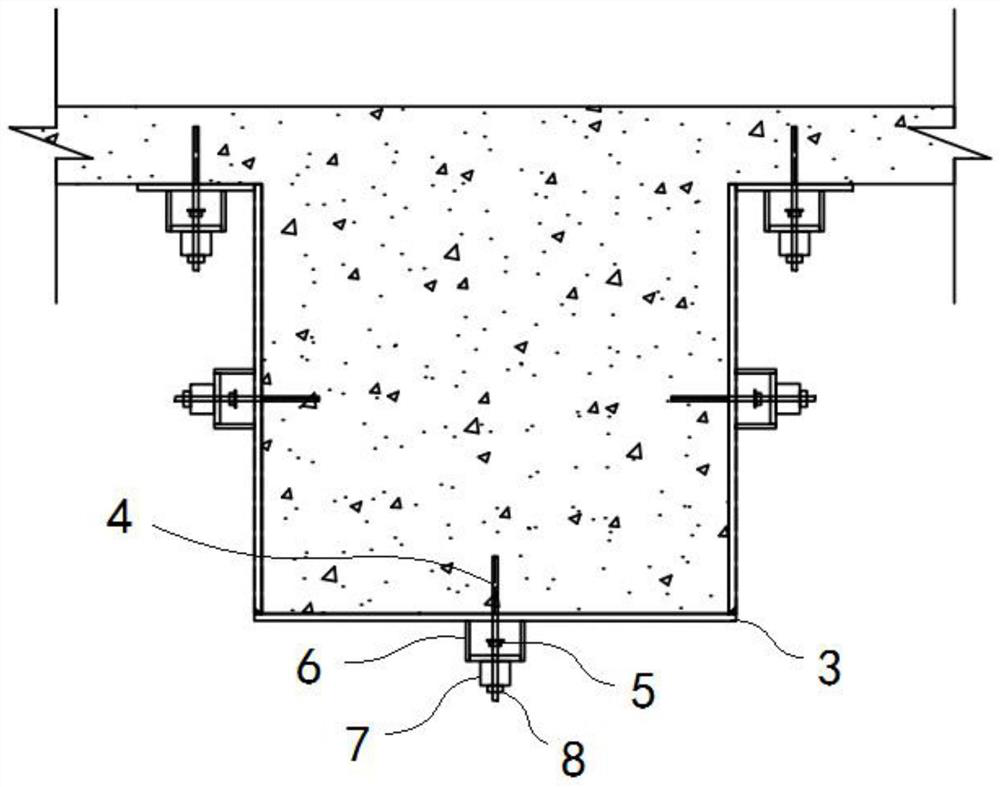

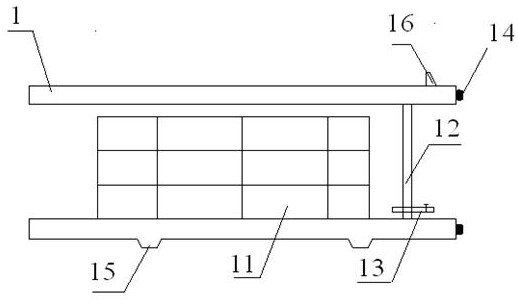

Construction method for reinforcing and reconstructing sticky steel plates of structure

InactiveCN111677324AGuarantee the construction qualitySave construction costBuilding repairsArchitectural engineeringLong span

The invention discloses a construction method for reinforcing and reconstructing sticky steel plates of a structure. Hydraulic stackers are adopted as lifting equipment, the steel plates are placed onthe hydraulic stackers and pushed to an area needing to be reinforced, and the construction method is simple, and saves the construction cost and the construction period; the plurality of hydraulic stackers can be adopted to operate simultaneously for reinforcing and reconstructing the sticky steel plates for a large-span civil engineering structure, the large-span steel plates are installed in place at time, and cutting and welding are not needed; after the steel plates are in place, a hydraulic drawing instrument is adopted at the position where the screws are implanted to tightly jack thesteel plates to a reinforce part, the thickness of the steel bonding glue can be reasonably controlled, and then the steel plates are fixed through positioning nuts, so that the steel plates are better bonded with the reinforcing part. According to different construction site conditions, different construction site environments and different shapes of required structural reinforcing components, the hydraulic stackers are refitted, and components such as supports and supporting tables related to steel plate bonding construction are additionally arranged.

Owner:广东精特建设工程有限公司

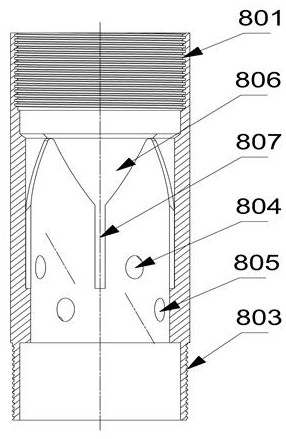

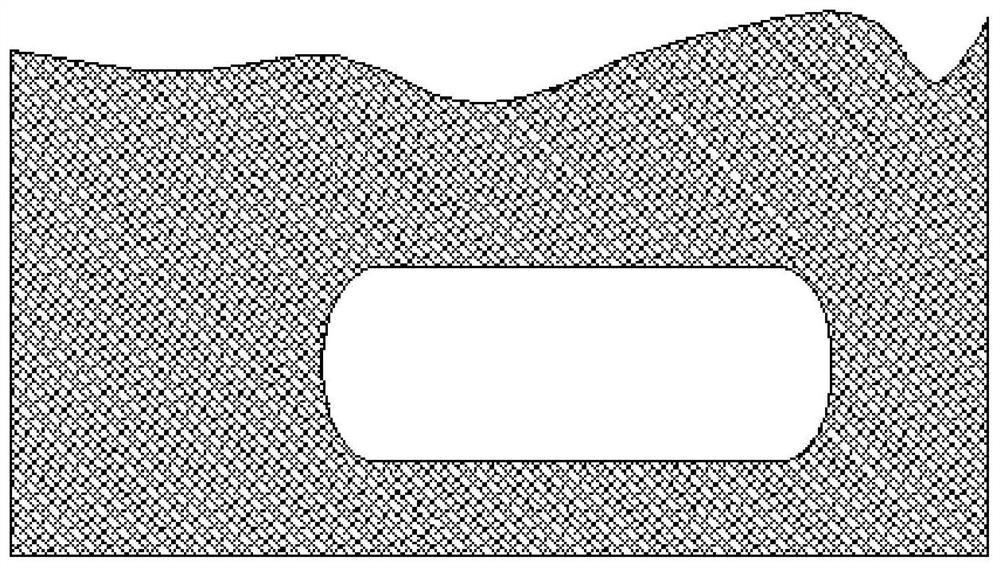

Dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and construction method

ActiveCN112982476AReduce the difficulty of site selectionAvoid influenceArtificial islandsUnderwater structuresAir volumeMarine engineering

The invention relates to a dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and a construction method. The basic structure unit used in the method has the following characteristics that the length of each basic structure unit is 20-25m, a sealing door is arranged at one end of each basic structure unit, the other end of each basic structure unit is of an open structure, and a drainage pressure relief valve is arranged at the lower end of each sealing door; a rubber water stop belt is arranged at the end of each basic structure unit in a surrounding mode, and a floating and ballasting cabin capable of adjusting the water inlet and drainage capacity is fixed in each basic structure unit; and at least four axis positioning foot stands are arranged at the bottom of each basic structure unit. The channel basic structure unit can be directly prefabricated on the flat ground, a large temporary dry dock does not need to be built, the temporary engineering investment is reduced, the manufacturing cost of an underwater channel is reduced, and the construction period of the underwater channel is shortened; and the basic structure unit can slide into a water area from a land area through a slideway, the basic structure unit is kept in a suspended state in water by adjusting the air volume in the floating and ballasting cabin, the basic structure unit is pulled and sunk by a floating crane ship, the construction efficiency is improved, and the water construction difficulty is reduced.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

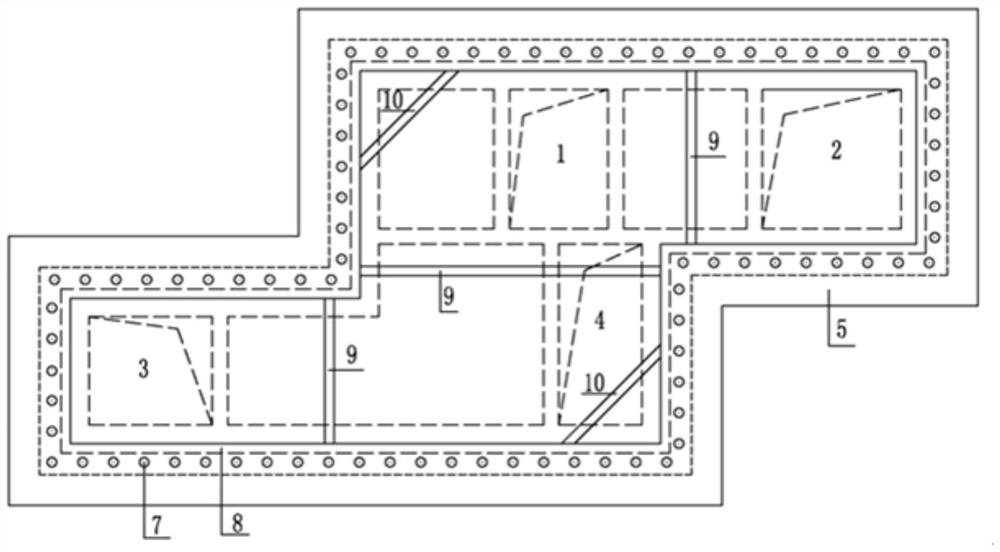

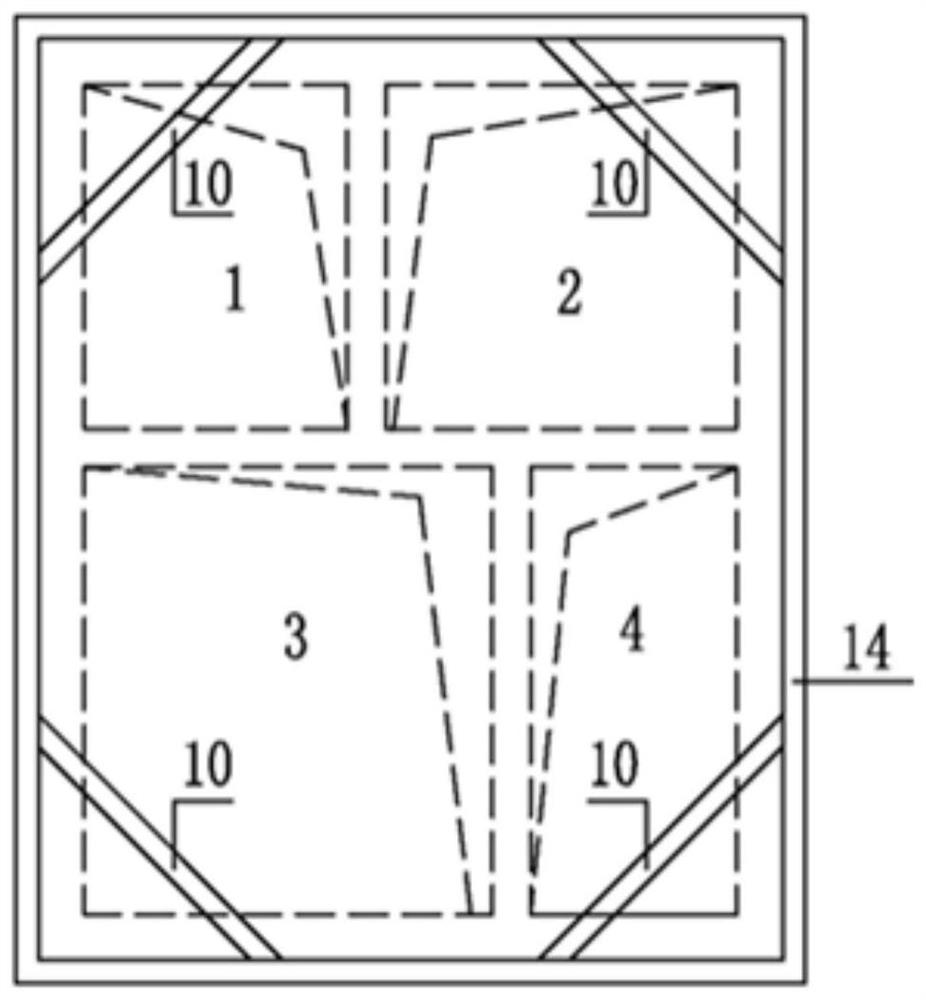

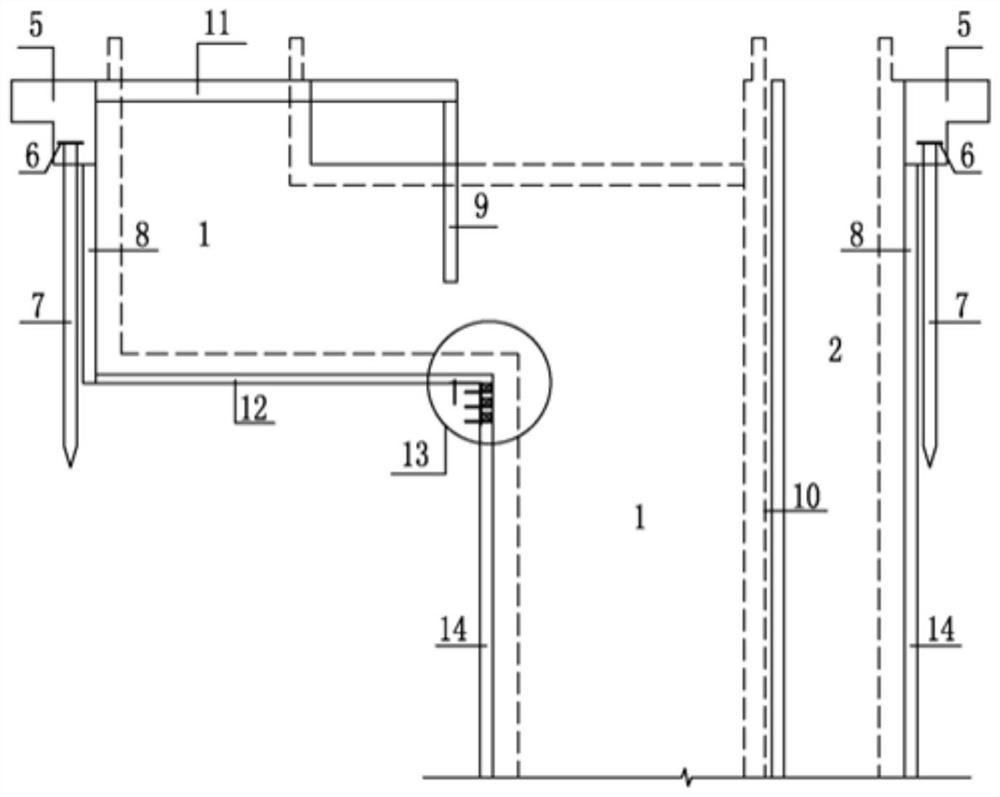

Special-shaped upside-down well wall construction method for simultaneously building vertical shaft and throwing-out air shaft

ActiveCN114183144AAvoid secondary reversal of the venueAvoid waste of engineering materialsHydro energy generationShaft sinkingArchitectural engineeringSteel frame

The invention provides a special-shaped upside-down hanging well wall construction method for simultaneously building a vertical shaft and a throwing-out air shaft. A steel pipe pile is driven, and the pile bottom enters the position below the foundation pit bottom of the throwing-out air shaft and serves as a temporary soil retaining component before primary support construction of the throwing-out air shaft; an opening shallow foundation pit is excavated, and an opening locking ring structure is molded; a rock-soil body is excavated downwards through a well wall upside down method, a throwing-out air shaft primary support is constructed, and throwing-out air shaft temporary section steel diagonal bracings and temporary section steel inclined bracings are erected; when excavation is conducted to the bottom elevation of the throwing-out air shaft foundation pit, a throwing-out air shaft foundation pit cushion layer is laid, and meanwhile a top cover plate is constructed to recover part of the construction site; the rock-soil body continues to be excavated downwards, a vertical shaft primary support and a temporary profile steel inclined strut are constructed, and an upper hanging and lower supporting structure is locally arranged on the first three steel frames of the vertical shaft primary support; and the vertical shaft continues to be excavated in a layering and blocking mode till the ingate holing elevation is reached, and steering air duct construction is prepared. Civil construction organization is convenient, and the mechanical work efficiency is high; and engineering materials are remarkably saved, and the civil engineering period is shortened.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST +1

Underground oil depot based on composite material bag body

InactiveCN113107248AImprove use valueExtended service lifeSynthetic resin layered productsBulk storage containerNatural resourceUnderground cavern

The invention discloses an underground oil depot based on a composite material bag body. An outer protection bag with the anti-cutting function is arranged in an underground oil storage cavity, and a flexible oil storage bag and a flexible liquid storage bag which are adjacently arranged in an up-down mode are arranged in the outer protection bag. The underground oil depot utilizes natural caves or manually excavated caves, so that the construction period and labor are greatly saved; the underground oil depot is close to a reservoir or an ocean, so that water supply is sufficient, and drainage is not limited by containing space; natural resources and existing resources are fully utilized, the cost is greatly reduced, and the construction time is shortened; the overground space is saved, the hidden developable space is great, and great significance is achieved for national defense construction; the outer protection bag with the anti-cutting function protects the flexible oil storage bag and the flexible liquid storage bag in a stable internal storage space, and the inner wall of the outer protection bag always keeps uniform pressure, so that the collapse of an underground cave under alternating internal pressure is avoided; and the oil depot is high in utilization value and long in service life and is not affected by the underground water level in use and installation.

Owner:连云港经纬复合新材料有限公司

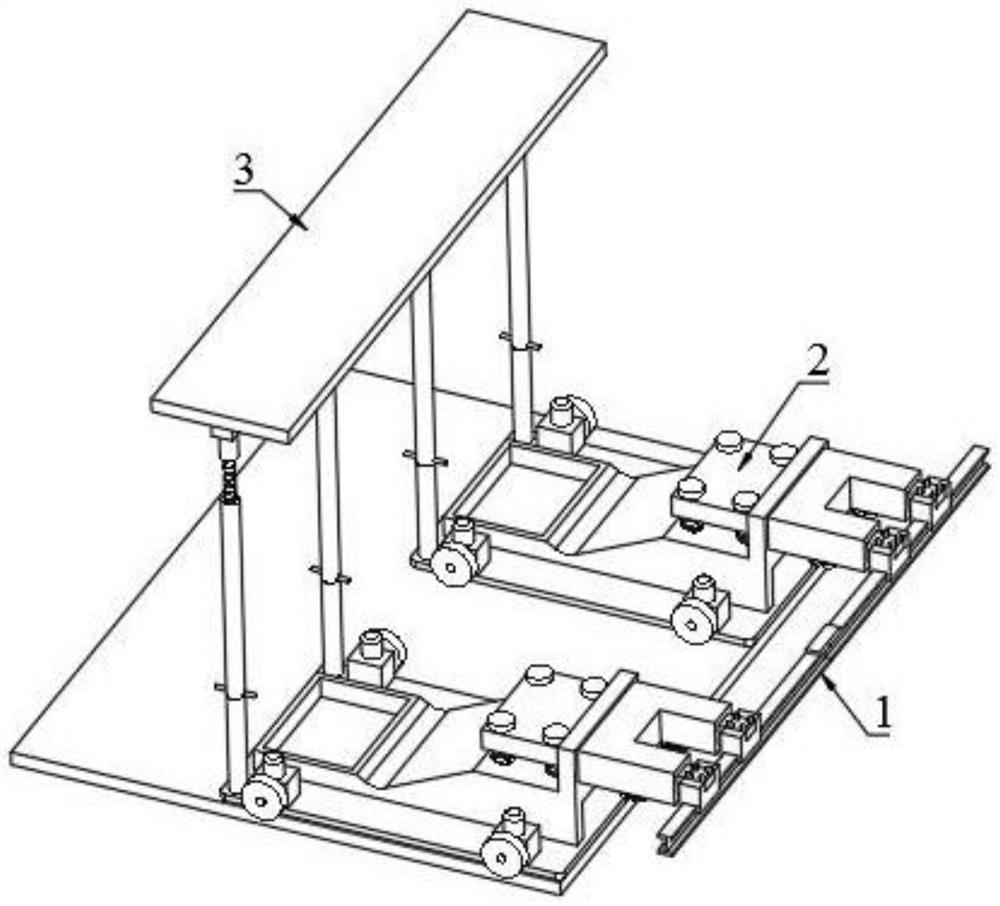

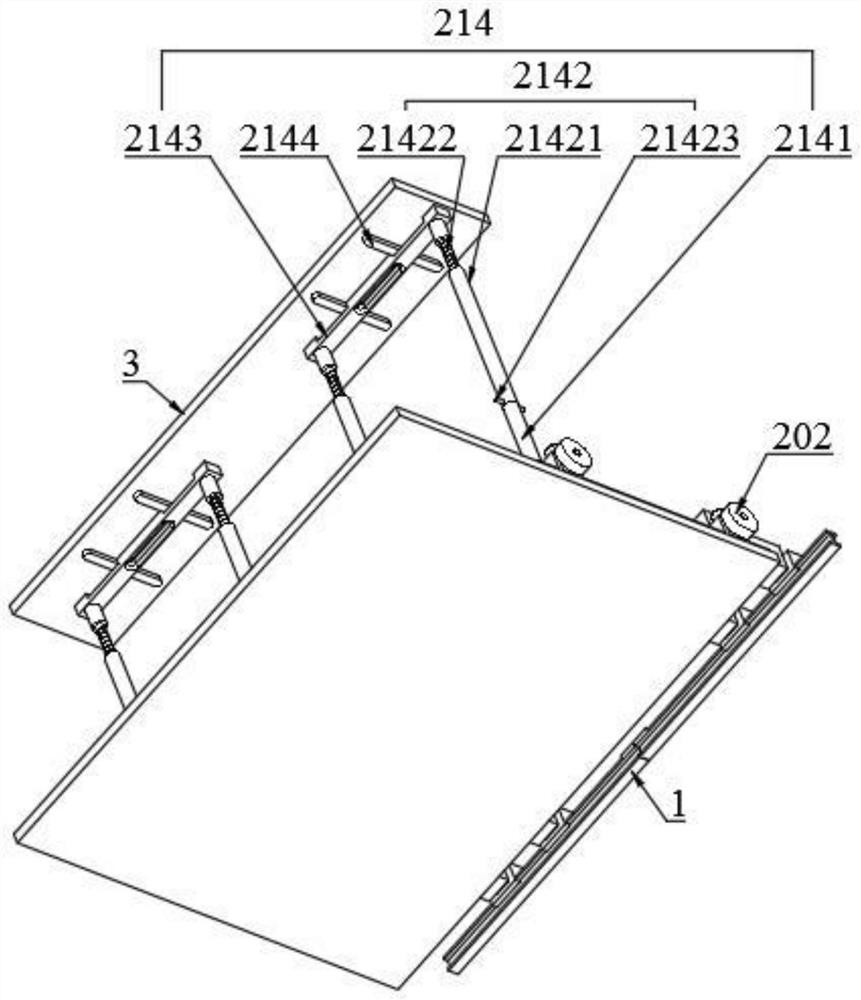

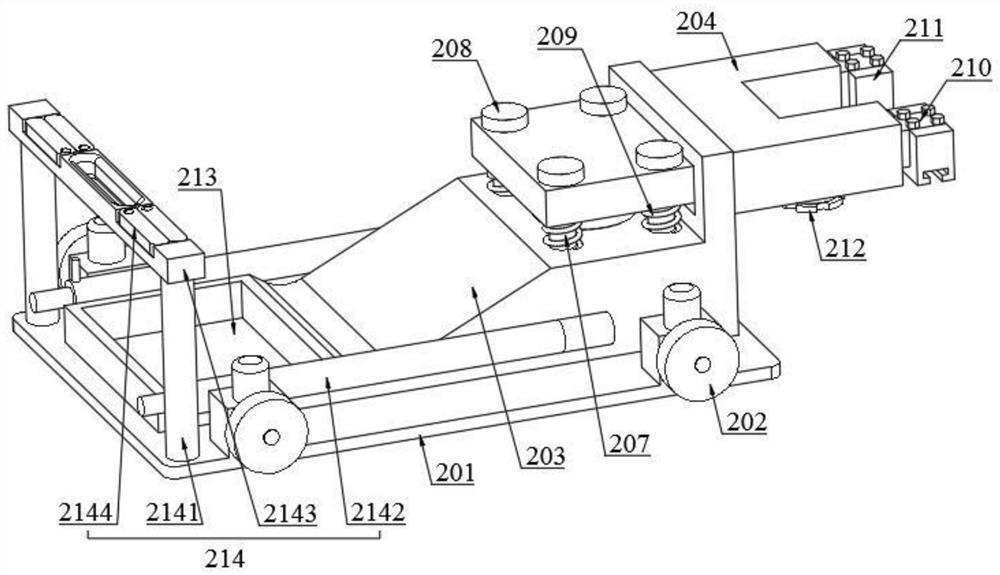

Unit type glass curtain wall hoisting equipment and construction method thereof

PendingCN114735589AImprove the level ofEasy and safe levelingRunwaysTrolleysScrew threadThreaded rod

The invention discloses glass curtain wall hoisting equipment and a construction method using the hoisting equipment. The equipment comprises an I-shaped rail, the top of the I-shaped rail is connected with a fixing device, and the bottom of the I-shaped rail is provided with an electric hoist hoisting platform; the fixing device comprises a base, rolling wheel mechanisms are fixedly connected to the four corners of the top of the base, a connecting frame is fixedly connected to the front side of the top of the base, a movable frame is slidably connected to the top of the connecting frame in a buckled mode, and a threaded rod is fixedly connected to the bottom of the tail side of the movable frame. The surface of the threaded rod is in threaded connection with an adjusting bolt located on the lower portion of the connecting frame, guide columns are arranged on the outer side of the threaded rod at equal intervals, and the guide columns are slidably connected with the movable frame. And operation outside the wall is needed, and the construction safety is poor.

Owner:中建新越建设工程有限公司

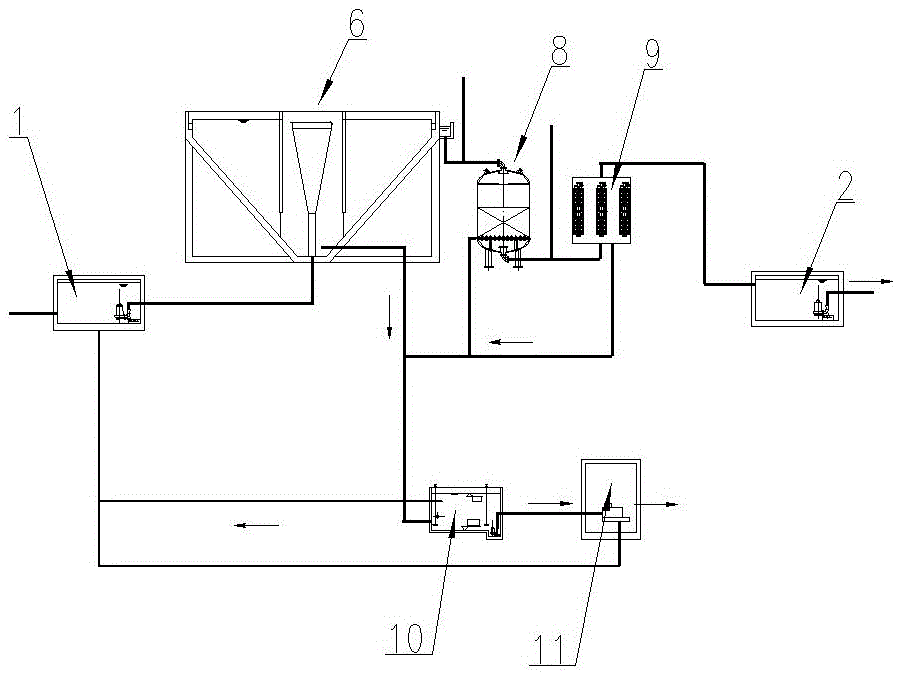

Double-effect flue gas purification apparatus and purification method thereof

InactiveCN104998535AIncrease contact areaHigh desulfurization rateUsing liquid separation agentCalcium/strontium/barium sulfatesPurification methodsSlurry

The present invention relates to the technical fields of general waste gas purification methods and equipment or apparatuses specially designed for the methods, particularly to a double-effect flue gas treatment apparatus and a desulfurization method thereof. According to the present invention, a layer of slurry spraying pipes are arranged at the positions 0.8-1 m above a flue gas treatment apparatus inlet flue, the plurality of the slurry spraying pipes are uniformly arranged on a circular absorption zone plane in a side-by-side manner, a plurality of spraying nozzles are uniformly arranged on each slurry spraying pipe in a side-by-side manner while the enough installation space is ensured, and the distance between the adjacent slurry spraying pipes, the distance between the adjacent spraying nozzles and the distance between the spraying nozzle and the tower wall are subjected to distance adjusting according to different flue gas purification apparatus sizes and difference slurry spraying amounts; with the apparatus and the method, the latest and most stringent environmental requirement that the SO2 emission concentration is lower than 50 mg / Nm<3> when the sulfur content in the combustion coal is less than or equal to 2.5% can be met so as to fill the technical gap, and the latest and most stringent flue dust emission requirements can be met when the concentration of the flue dust at the flue gas treatment apparatus inlet is less than 80 mg / Nm<3>; and the operating cost of the whole system is low, security and stability are provided, and use range is wide.

Owner:SHANGHAI INNOVATE ENVIRONMENTAL PROTECTION TECH

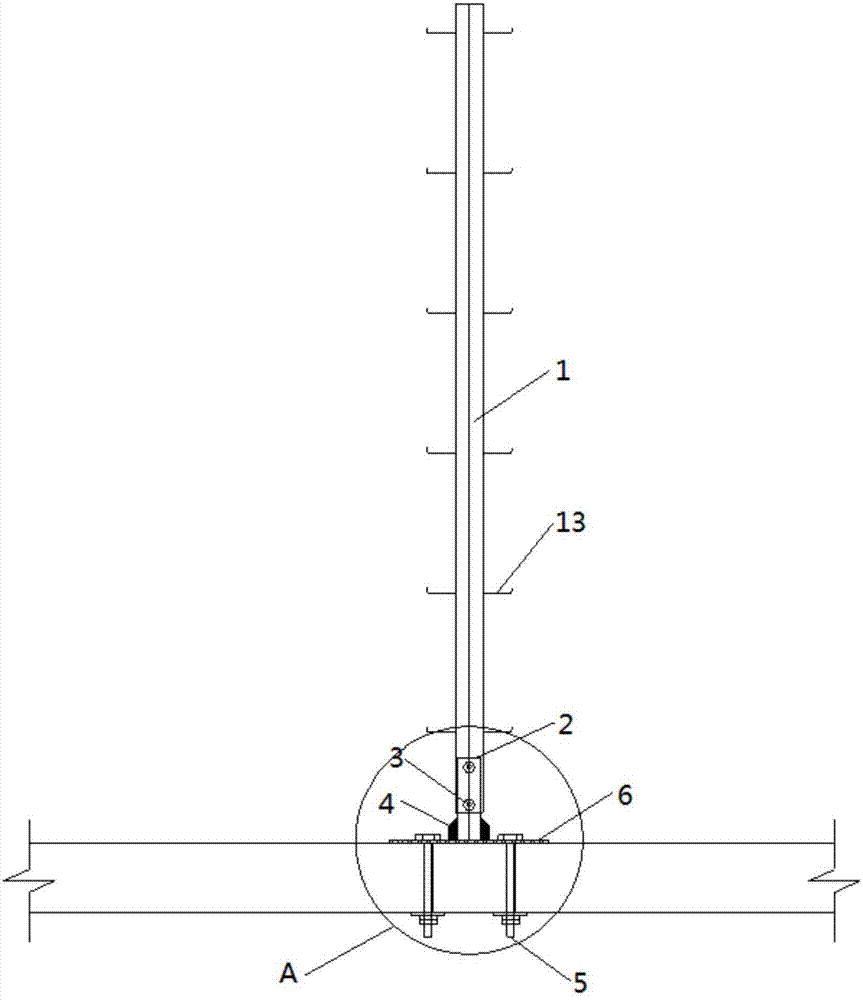

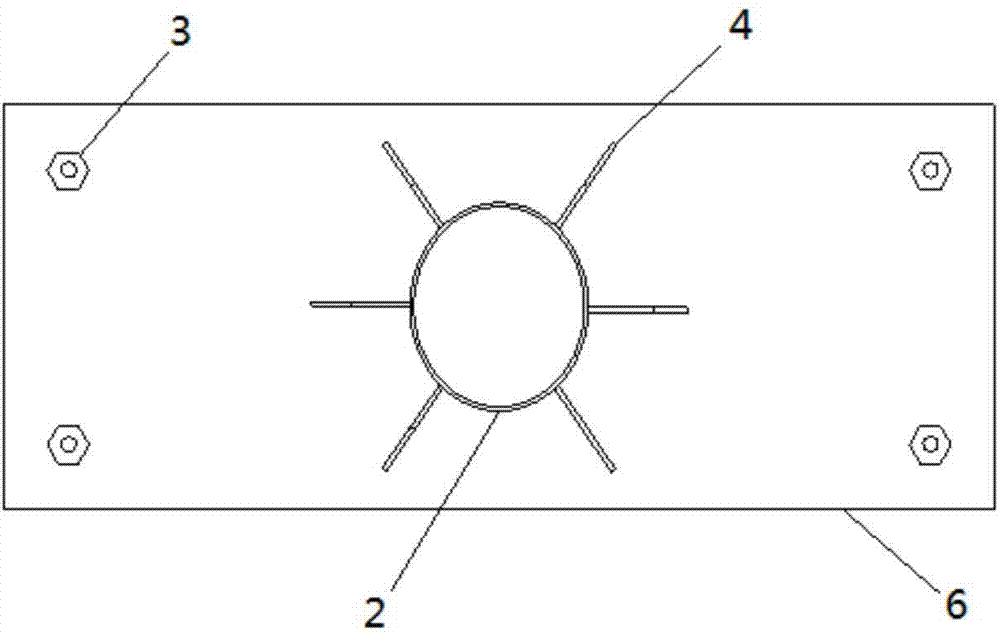

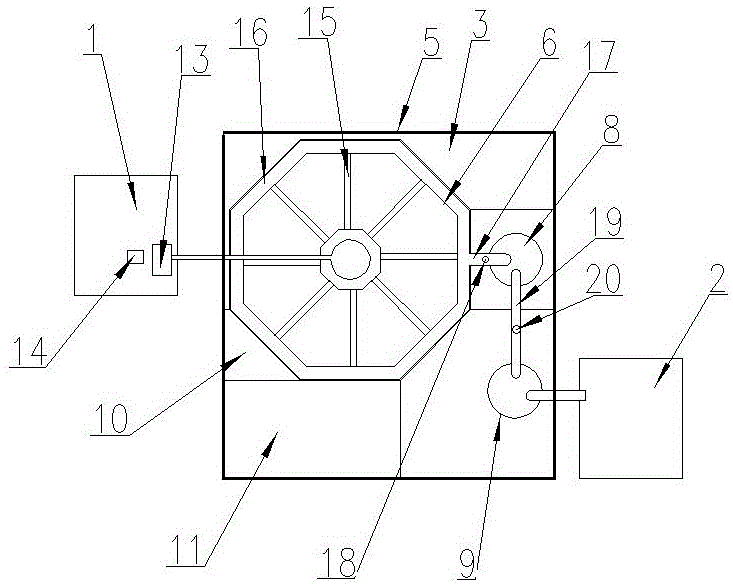

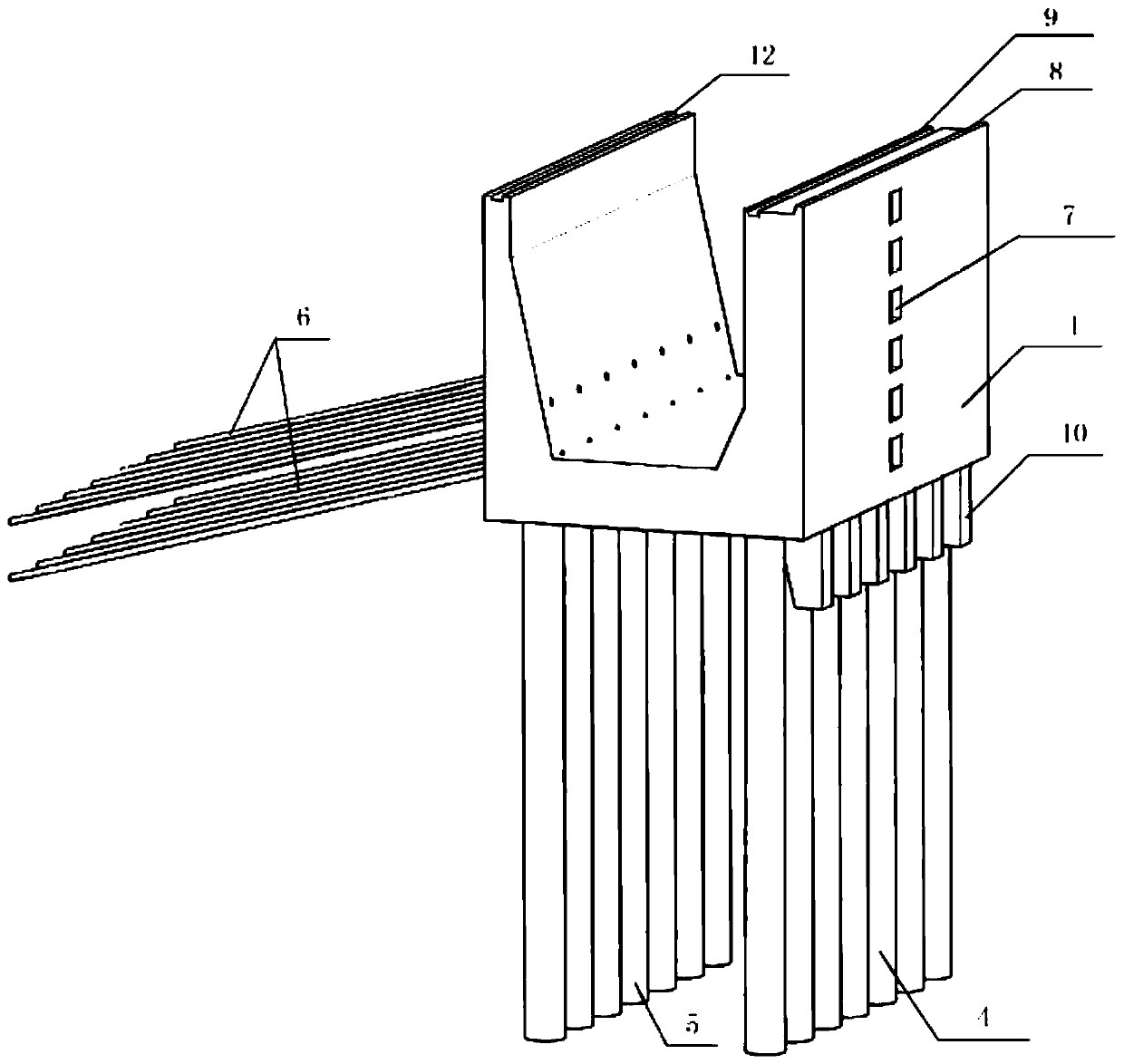

Supporting part of reinforcement cage and application method thereof

The invention discloses a supporting part of a reinforcement cage and an application method thereof. The supporting part comprises a bar I, a connecting part and a bar II. The connecting part comprises a "-"-shaped bar part, the bar I and the bar II are separately connected to two ends of the "-"-shaped bar part, the bar I and the bar II are collinear, slots are connected to the bar I and the barII, separately, the notches of the two slots are formed in directions, far away from the connecting part, and the pitch between the two slots is adjustable. By adopting the device, the reinforcement cage can be supported effectively, the integral strength of the reinforcement cage is improved, deformation of the reinforcement cage in hoisting and conveying processes is avoided, the quality of thereinforcement cage is guaranteed, and the hole forming quality of a pile foundation is improved. The supporting part is convenient to detach and mount and can be repeatedly used, so that the safety ofthe hoisting process is improved. Meanwhile, damage caused by welding and cutting operations and welding and cutting on the reinforcement cage is avoided, the use level of supporting reinforcing steel bars is saved greatly, and the mounting and detaching work efficiency is improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Graphite grounding body beneficial for conduction and processing technology

InactiveCN109888519ADoes not rustStable grounding resistanceLine/current collector detailsConnection contact member materialPower flowSoil resistivity

The invention relates to a flexible graphite grounding body beneficial for conduction. The flexible graphite grounding body comprises an inner-layer graphite harness and a graphite line weaving layer,wherein the inner-layer graphite hardness comprises graphite lines arranged in parallel, and the outer-layer graphite line weaving layer is obtained by weaving the graphite lines. The flexible graphite grounding body has the advantages of corrosion resistance, no rust, no large-current impact, high- and low-temperature resistance, stable grounding resistance, maintenance free, updating free, safety and reliability and is suitably used in acid land, alkali land, wetland, hot wet place, sea salt and mountains and hills which are difficult to construct and is relatively high in soil resistivity.

Owner:四川健坤科技有限公司 +1

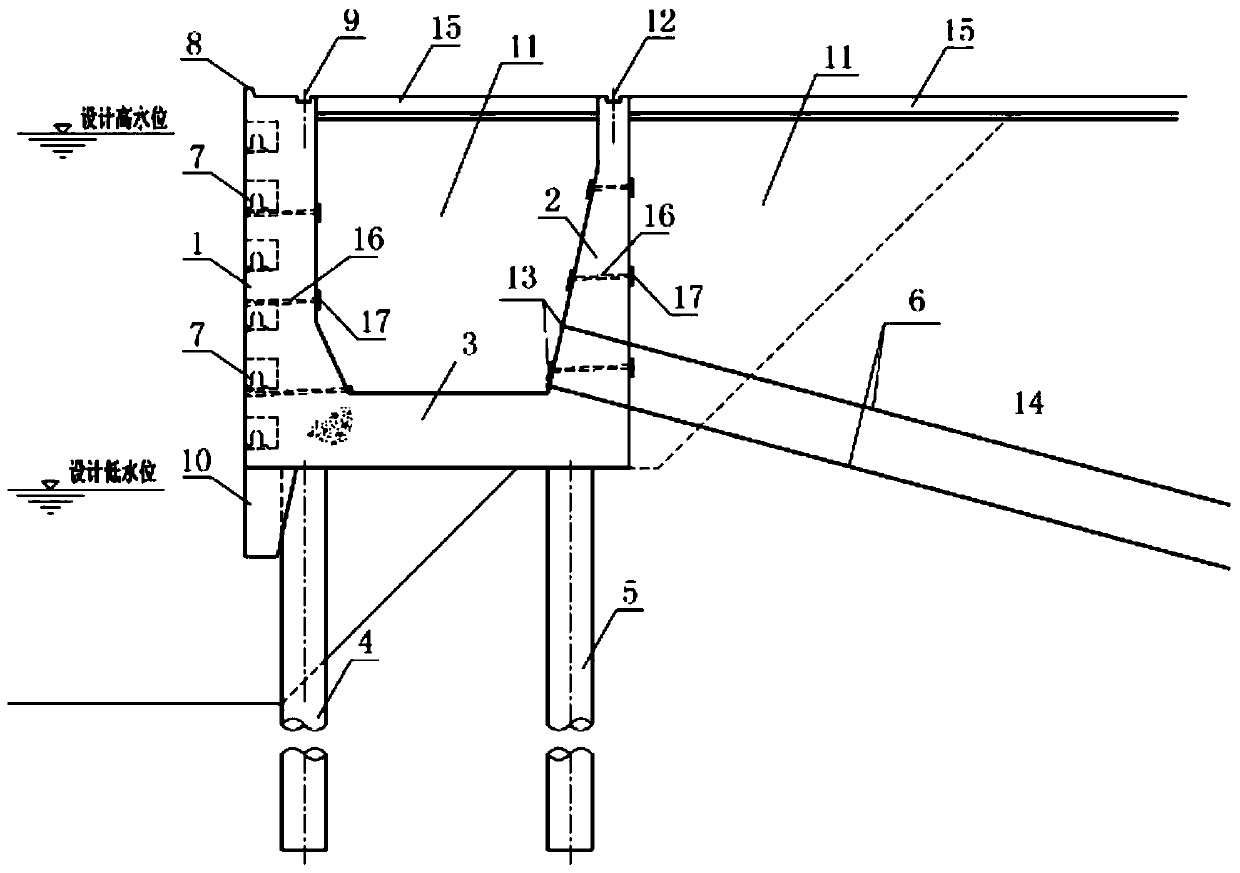

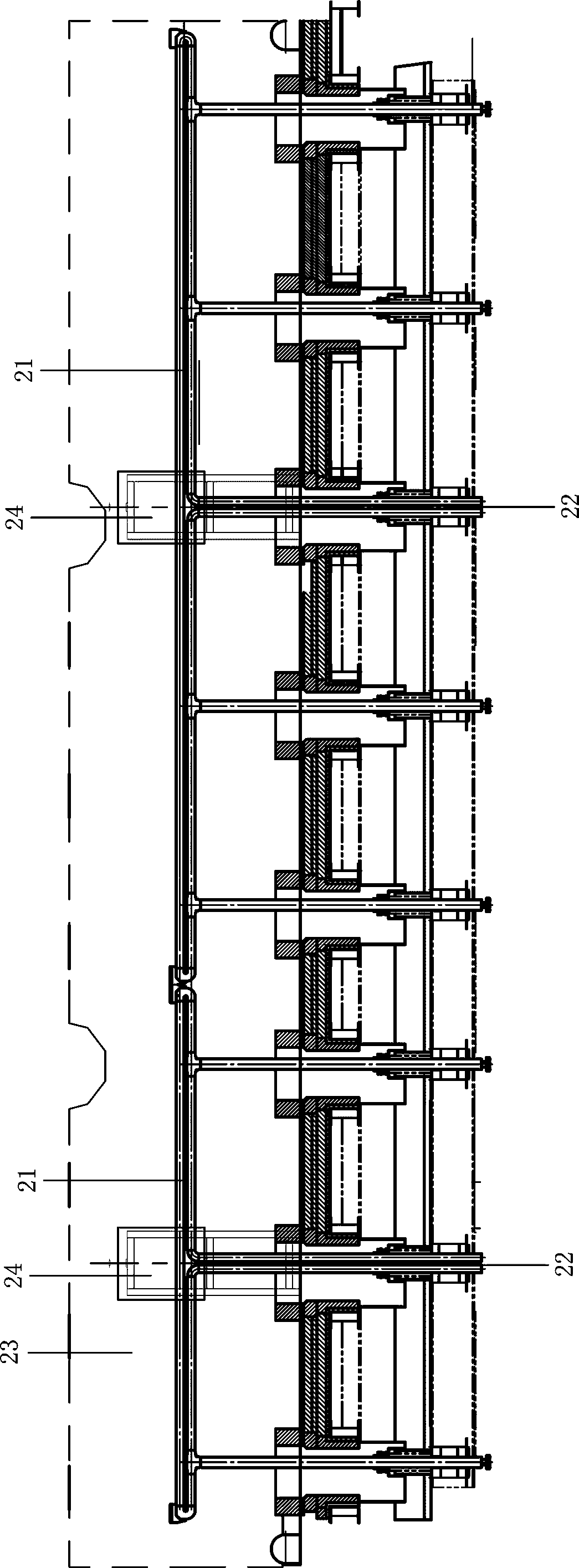

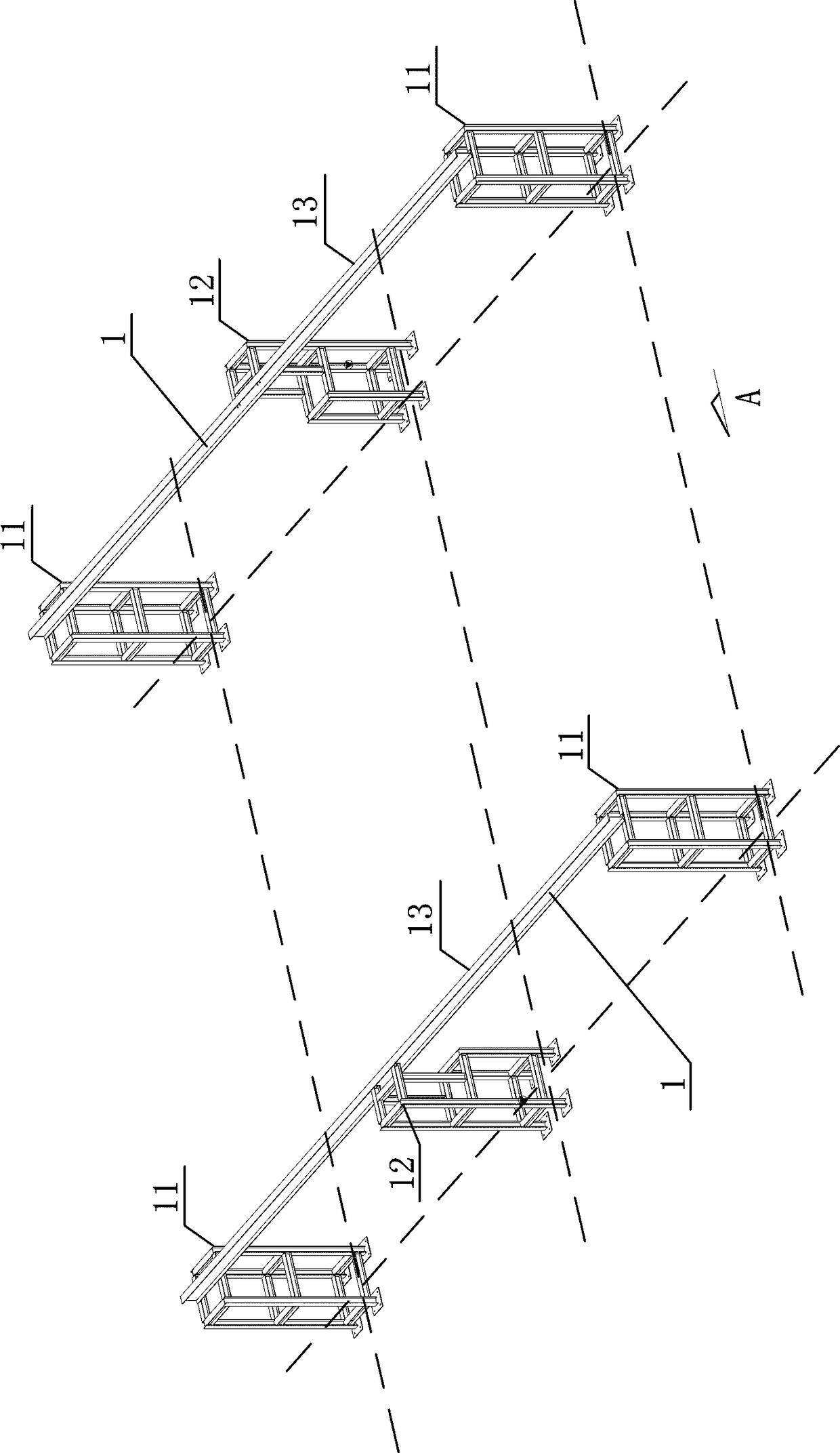

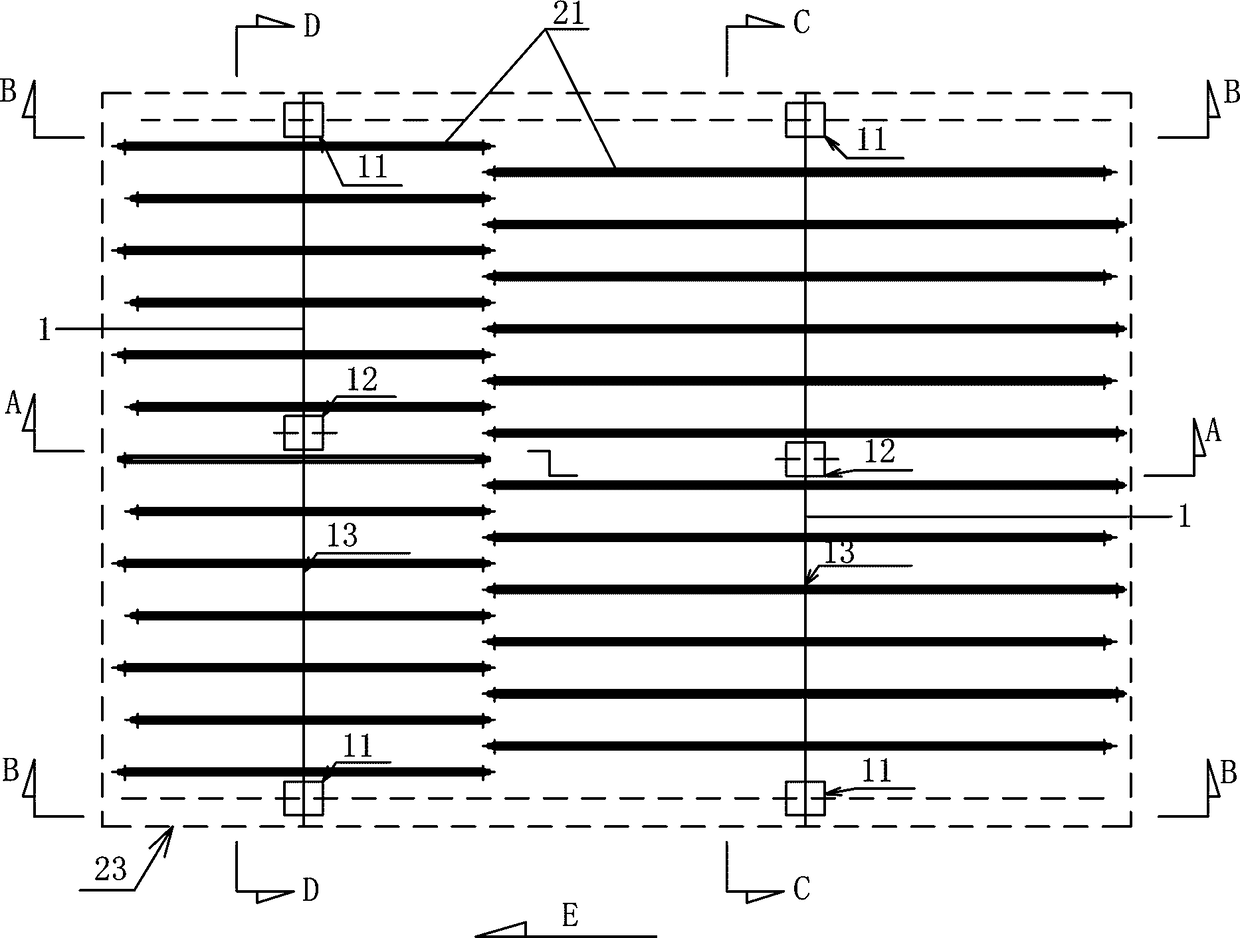

Mountain river wharf structure

PendingCN111424608AGuaranteed uptimeReduce the excavation heightBreakwatersQuaysEngineeringOceanography

The invention discloses a mountain river wharf structure. The mountain river wharf structure comprises two sets of row piles arranged in the upstream and downstream direction of a mountain river in parallel and a U-shaped structure arranged at the tops of the row piles. The U-shaped structure comprises two sets of walls vertically arranged along the tops of the row piles and a bearing table connected with the tops of the row piles and the bottoms of the walls. The top of the U-shaped structure is covered with a surface layer. Rails are further arranged at the tops of the walls. The U-shaped structure is provided with two rows of anchor rods to be anchored into rock soil. The mountain river wharf structure can meet the ship tying requirements on different water levels, the problems of settlement and deformation of equipment rails are solved, structure stress is reasonable, construction can be directly carried out on abrupt slopes, the mountain river wharf structure is safe, reliable, economical and reasonable, and construction is convenient.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

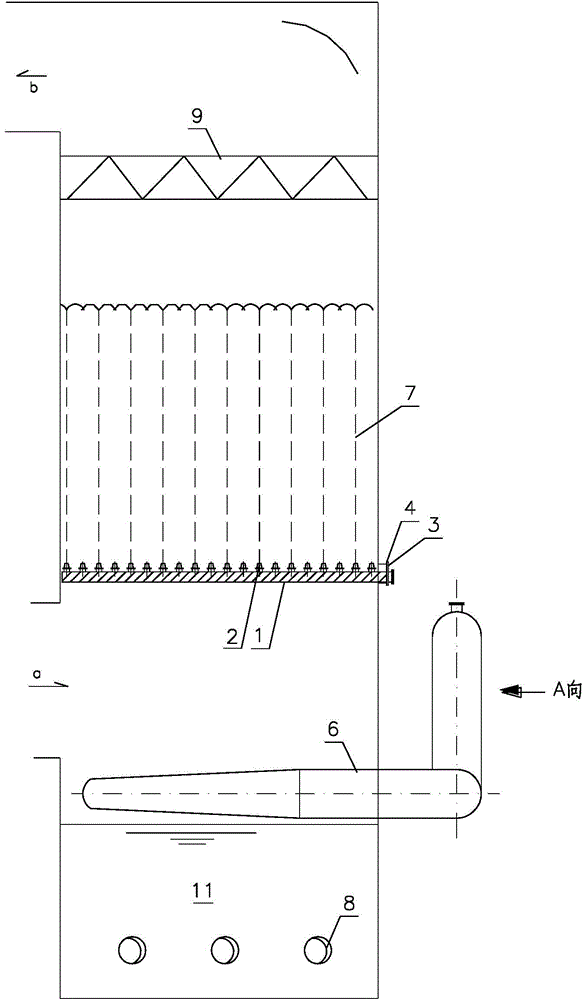

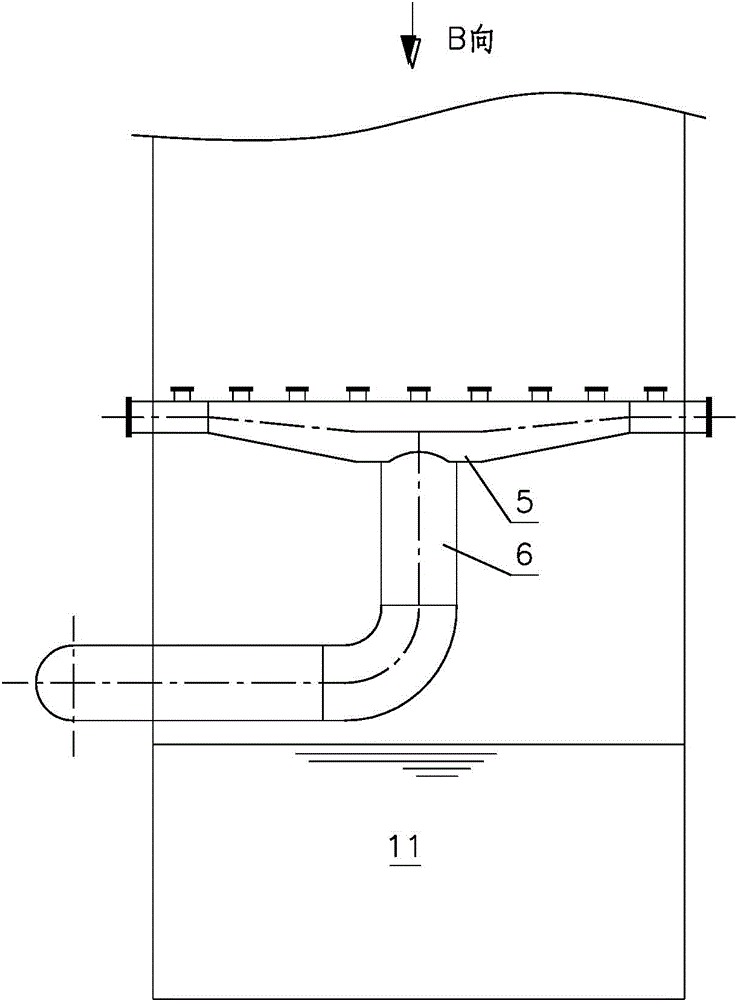

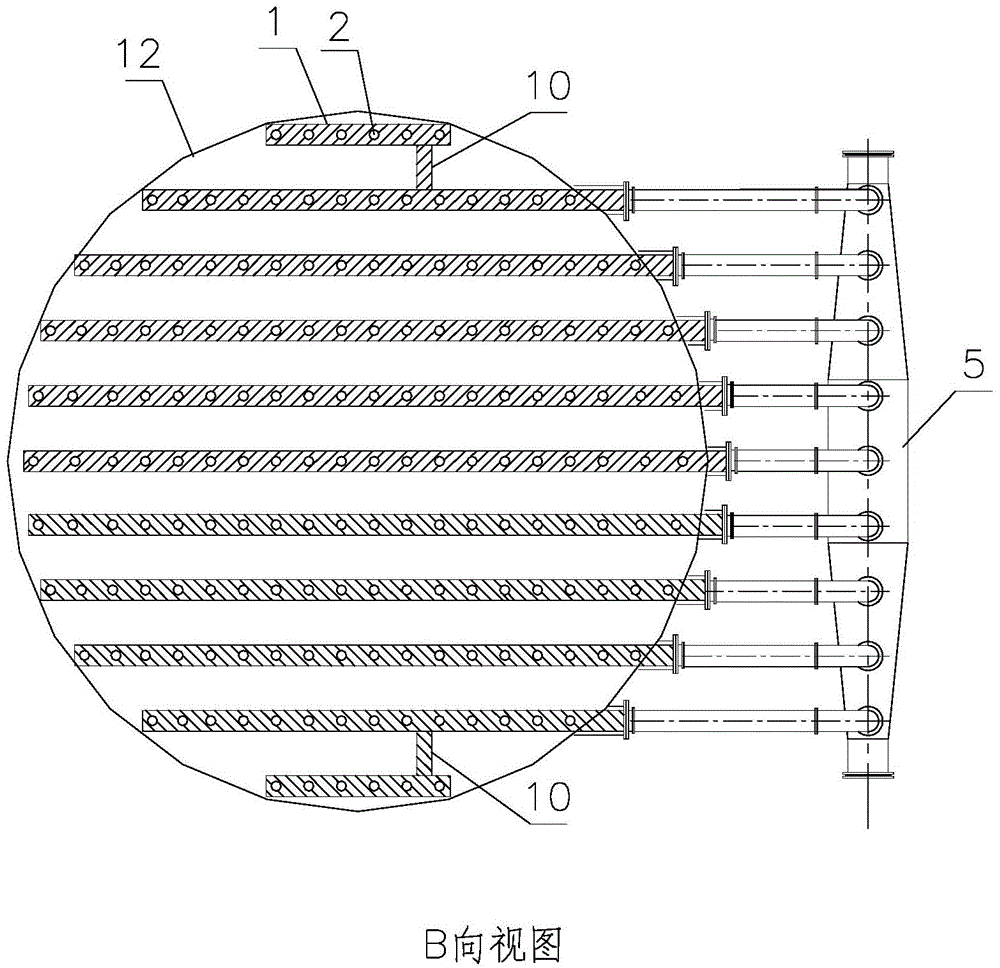

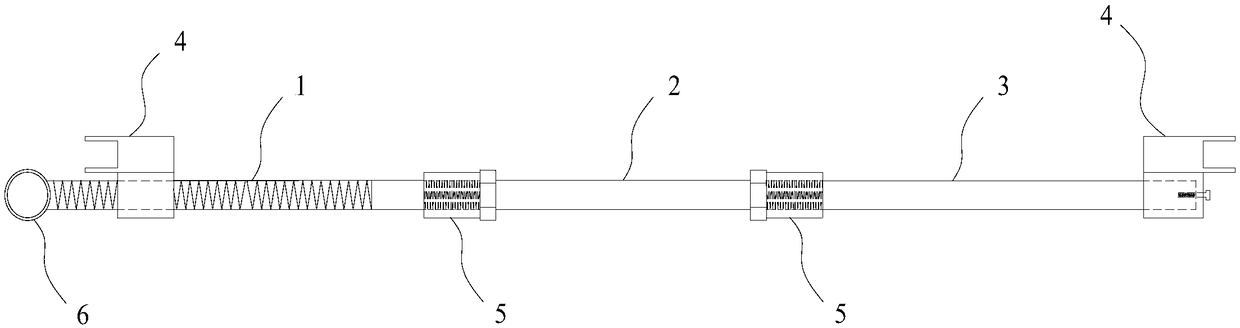

Fast disassembling and replacing construction method for water beams of step-type heating furnace

InactiveCN109210933ASolve the demolition problemSolve replacementLinings repairFurnace typesEngineeringHeating furnace

The invention relates to the field of construction and repair of furnace linings, in particular to a fast disassembling and replacing construction method for water beams of a step-type heating furnace. The fast disassembling and replacing construction method for the water beams of the step-type heating furnace is characterized in that two groups of water beams (21) which are arranged in parallel are arranged in a step-type heating furnace body, the two groups of water beams comprise a group of long water beams and a group of short water beams, and all the water beams (21) are horizontally erected on water beam stand columns (22); and a sealing box is further arranged in the step-type heating furnace body, and the two opposite sides of the step-type heating furnace body are a rolling mill side and an operation side respectively. The method is characterized by comprising the following steps that 1, holes are formed; 2, supporting parts are manufactured; 3, hanging is carried out; 4, hoisting is carried out; 5, transferring is carried out; 6, the stand columns are disassembled; 7, the water beams are replaced; 8, cleaning is carried out; and 9, repairing is carried out. The construction method has the advantages of being convenient to operate, short in time consumption, high in production efficiency and high in environmental adaptability.

Owner:CHINA MCC20 GRP CORP

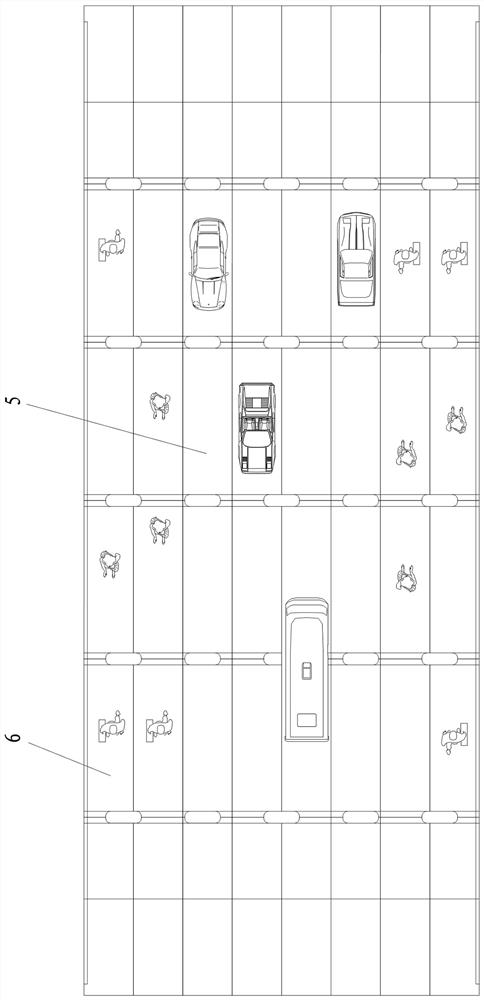

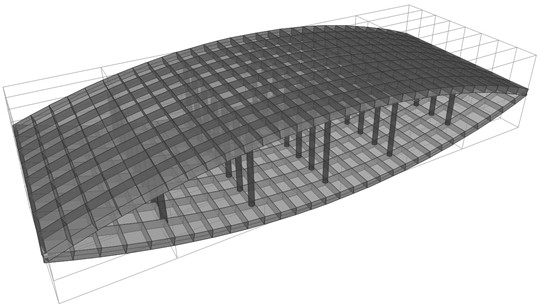

Fabricated laminated slab few-support erection construction method

PendingCN114233048AEasy to installReduce investmentFloorsBuilding material handlingSupporting systemArchitectural engineering

The invention discloses a few-support erecting construction method for fabricated laminated slabs, and belongs to the technical field of hoisting construction of fabricated building laminated slabs. According to the method, the frame superposed beams are hoisted according to requirements to be fixed and positioned, split bolt holes used for installing the plate bottom supporting steel corbels of the superposed plates are reserved in the superposed beams, single-row or double-row independent supporting frame bodies are erected according to the size of the prefabricated superposed plates, and the plate bottom supporting steel corbels and the independent supporting frame bodies are well adjusted according to the designed elevation and positioning; hoisting construction of the prefabricated laminated slab can be carried out; and plate bottom supporting steel corbels are fixed to the frame superposed beams, independent supporting frame bodies are erected between the superposed beams, the height is adjusted according to design requirements, and after the plate bottom supporting steel corbels and the independent supporting frame bodies are adjusted, the prefabricated superposed plates are hoisted to complete assembly construction. According to the composite slab supporting system, the composite beams and the composite slabs are erected through the rigidity and bearing capacity of the composite beams and the composite slabs, the composite slab supporting system is formed through the slab bottom supporting steel corbels and the independent supporting frame bodies, and the composite slab supporting system which is large in spacing, small in number and high in stability is formed.

Owner:中建科技有限公司华东分公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com