Non-bracket cable truss construction method for lifting entire body by obliquely drawing fixed jack

A technology of overall improvement and construction method, applied in the processing of building materials, construction, building construction, etc., to reduce safety risks, improve efficiency, and avoid safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

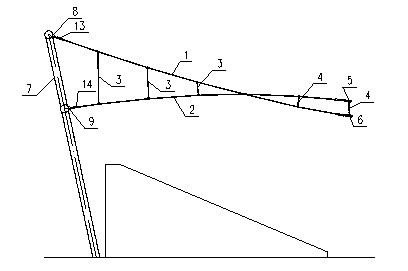

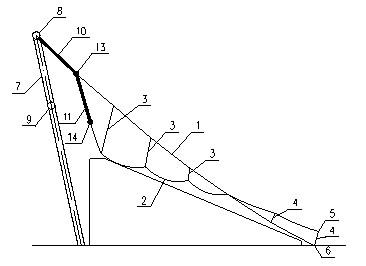

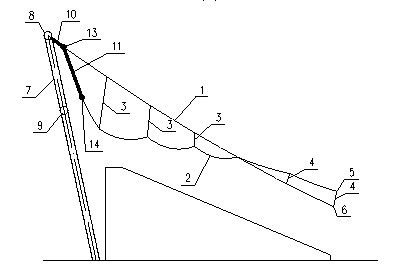

[0041] Taking the ring-spoke cable truss canopy of a stadium as an example, the specific implementation steps and methods are as follows:

[0042] 2) When making the cable, it should be made according to the production length under the design cable force; the cable should be pre-tensioned to eliminate inelastic deformation; the cable should be marked on the surface of the cable body under the design cable force. Clamping position, marking the adjustment position corresponding to the designed and manufactured length on the cable head adjusting device, and marking a straight line on the cable body.

[0043] 3) Install the surrounding structure of the cable truss, and install the tooling ear plate at the anchor node of the cable.

[0044] 4) Arrange the ground and stand surface; when the cable is transported to the construction site, it should be deployed along the straight line on the surface of the cable body to ensure that the cable body does not twist.

[0045] 5) Assemble the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com