Fast disassembling and replacing construction method for water beams of step-type heating furnace

A technology of a walking heating furnace and a construction method, which is applied to lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of restricting the continuous utilization of the walking heating furnace, failing to meet the design requirements, and low utilization rate of the heating furnace. , to achieve the effect of reducing labor output cost, saving construction period and material cost, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

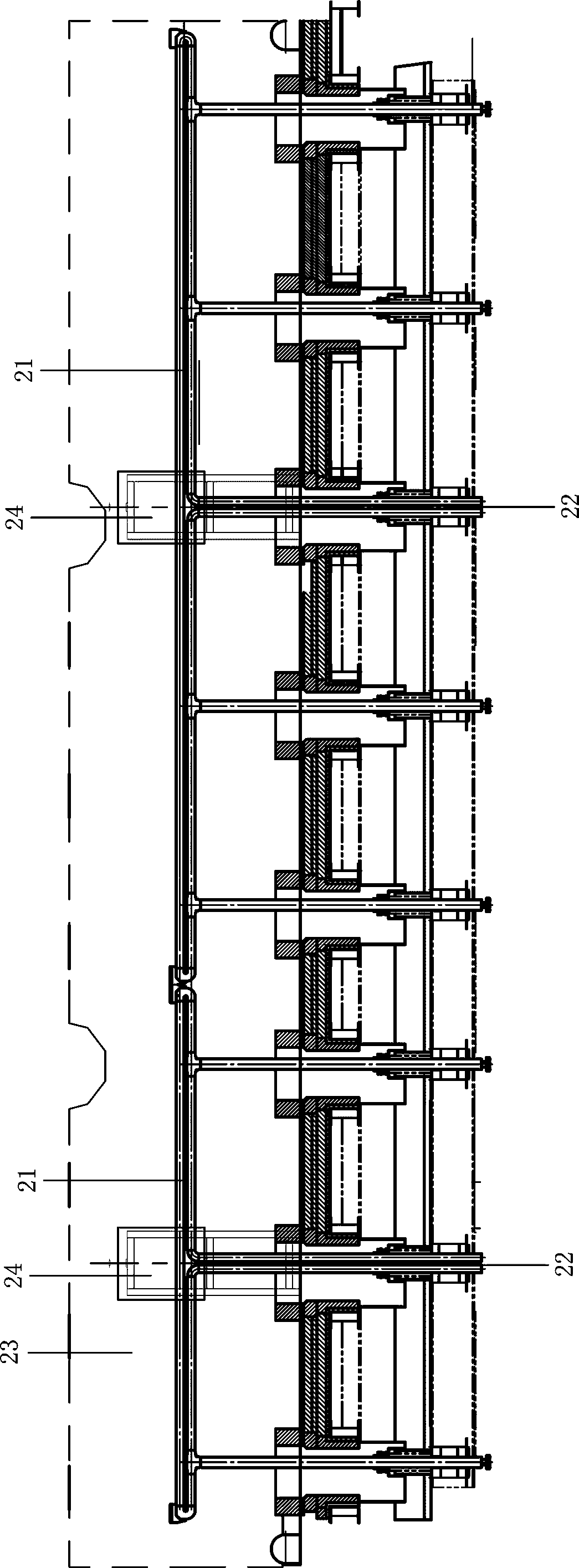

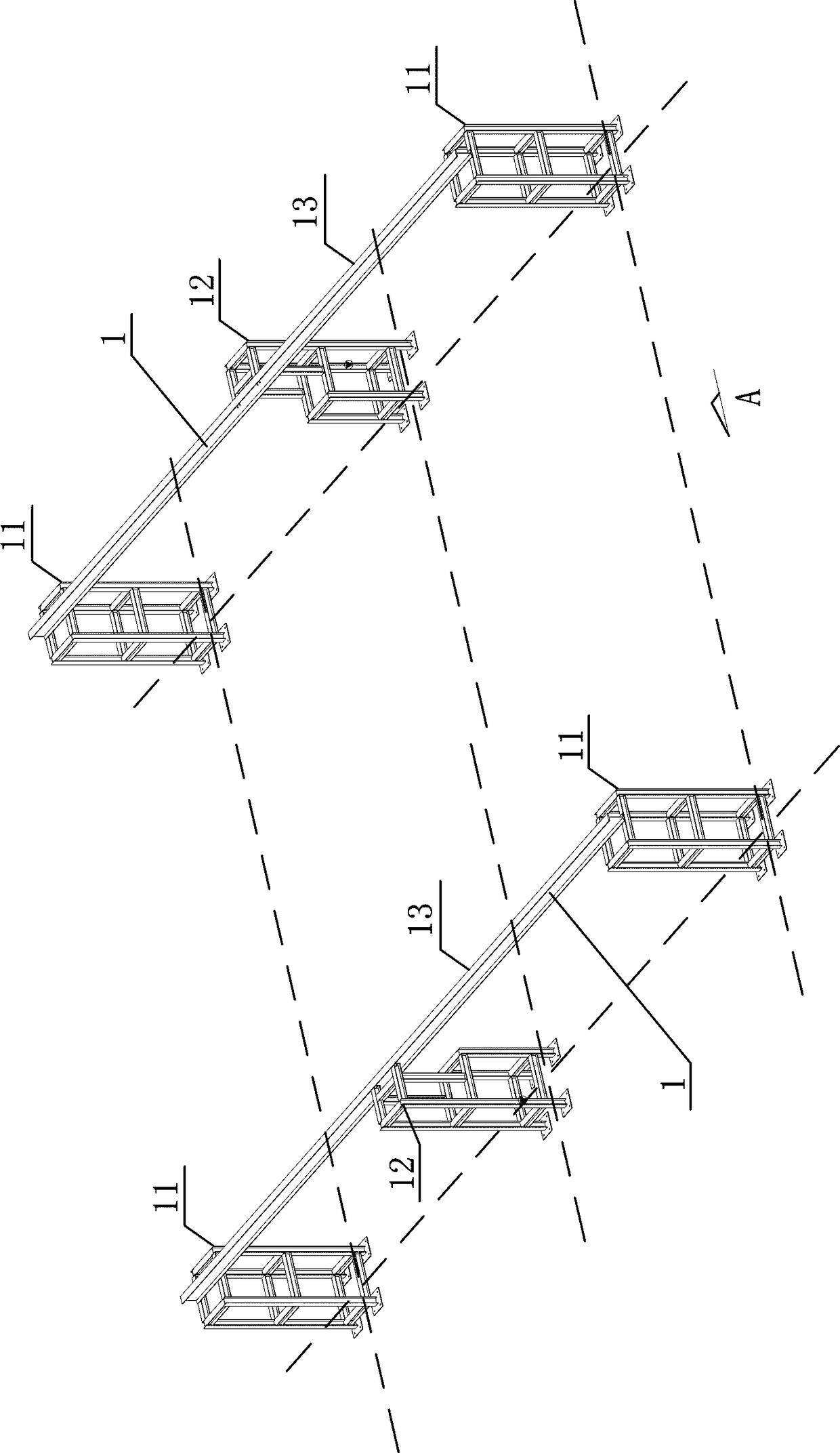

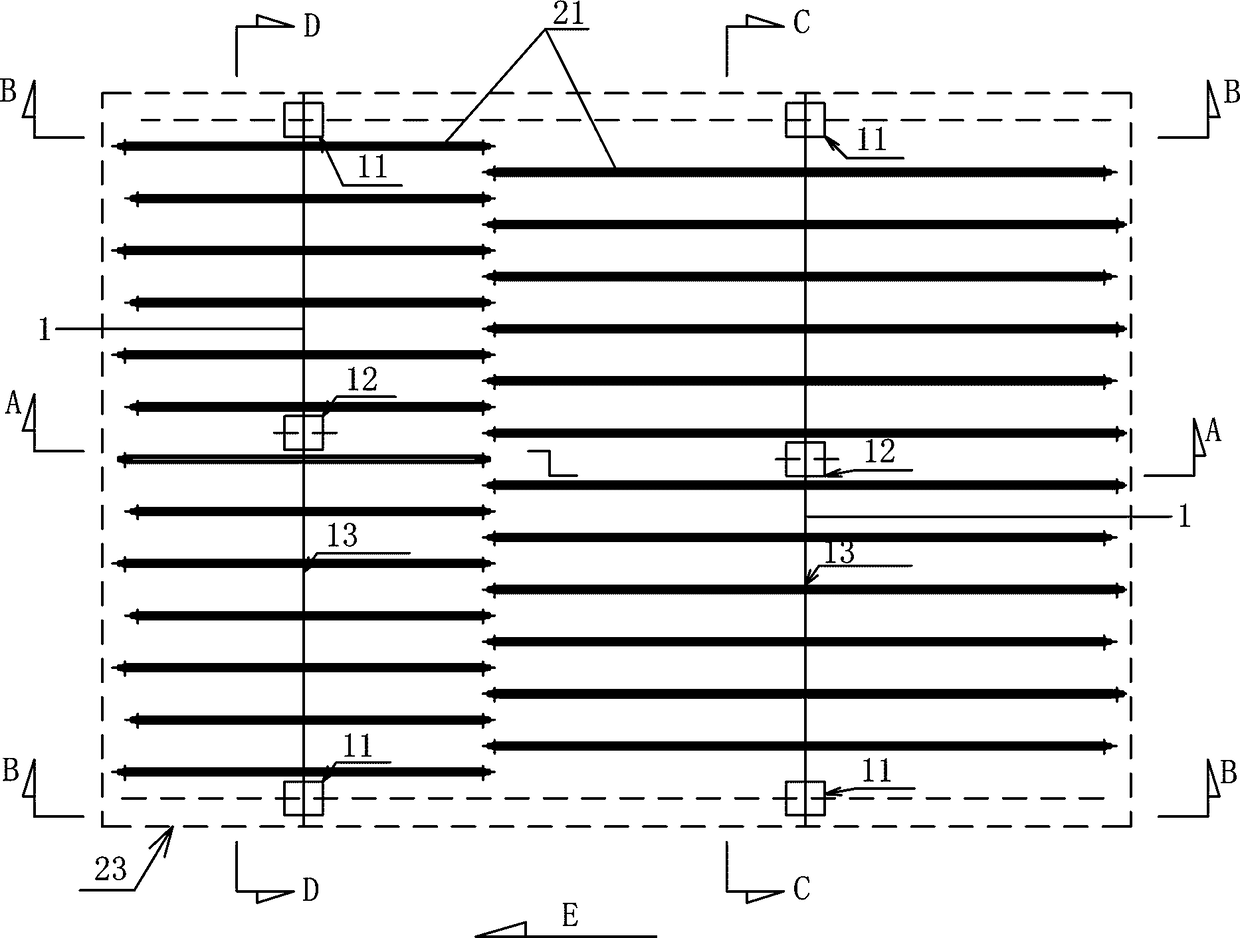

[0035] A construction method for quickly dismantling and replacing water beams of a walking heating furnace. Two sets of water beams 21 arranged parallel to each other are arranged in the furnace body of a walking heating furnace, which are respectively a group of long water beams and a group of short water beams. The water beams 21 are all erected horizontally on the water beam column 22, and a sealed box is also provided in the furnace body of the walking heating furnace. The opposite sides of the furnace body of the walking heating furnace are respectively the rolling mill side and the operation side, as follows Implement in turn:

[0036] i. Opening: such as figure 1 Shown: On the side wall 23 of the walking heating furnace body rolling mill side, at the center of the long water beam and the center of the short water beam, respectively open a square hole with a height of 1.2 meters and a width of 1 meter 24, the square hole 24 runs through the side wall body and the refra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com