KTCS small bearing lock upper lock body removal tool and method

A dismantling tool and small-sized technology, which is applied in the field of dismantling tools for the KTCS small force-bearing lock body of the aircraft cover, can solve the problems of easy-cut wound cover, low work efficiency, and affecting the quality of aircraft products, so as to ensure the surface quality and improve the quality of aircraft products. Work efficiency, the effect of solving demolition problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Attached below Figure 2-4 The present invention is described in further detail:

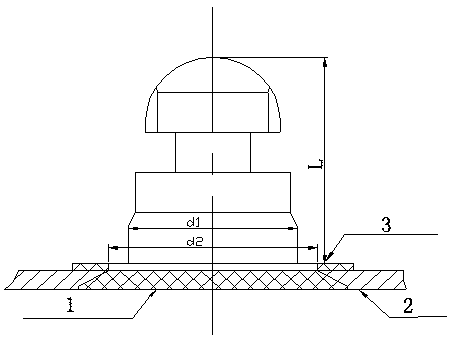

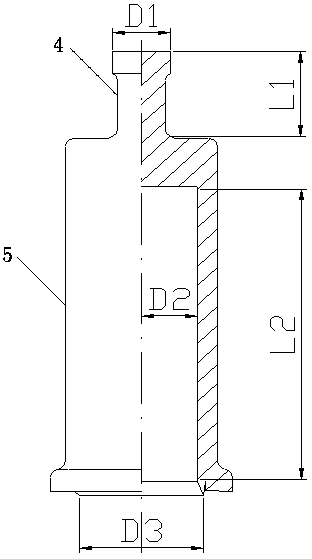

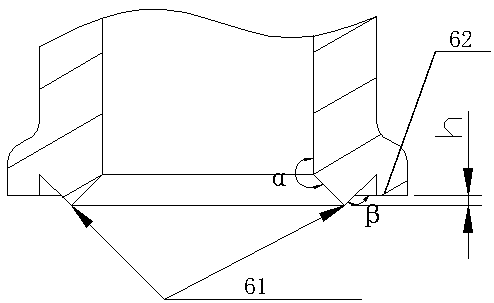

[0023] Such as figure 2 As shown, the KTCS small-sized load-bearing lock lock body removal tool 100 is an integral structure, which is divided into a top protrusion 4, a hollow cavity 5 and a bottom cutting and flanging part. The top protrusion 4 is the hammering part: the specific size is: D1=10~12, L1=15; the hollow cavity 5 is the middle part to accommodate the KTCS small load-bearing lock body, and the specific size requirements are: D2=d1+1, L2 =L+10; the bottom cutting flanging part consists of two parts, one part is the cutting edge 61, and the other part is the limiting part 62, such as figure 2 , 3 As shown, the specific size is: D3=d2+2 h=δ.

[0024] Note: D1-the diameter of the hammering part; D2-the diameter of the inner cavity in the middle;

[0025] L1 - top height; L2 - cavity height;

[0026] d1-inner diameter of upper lock body; d2-outer diameter of upper lock bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com