Graphite grounding body beneficial for conduction and processing technology

A technology of graphite body and grounding body, which is applied in the direction of circuits, connections, electrical components, etc., can solve the problems of hidden dangers in the power system, difficulties in transportation and construction, and high maintenance costs, and achieve the goals of saving construction period, significant grounding effect, and saving land resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

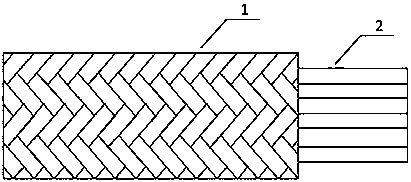

Image

Examples

Embodiment 1

[0023] A kind of manufacture technology that is conducive to the flexible graphite grounding body of electric conduction, comprises the following steps:

[0024] S1. Choose graphite with a carbon content ≥ 99%. After washing with water, washing with concentrated sulfuric acid, and drying, expand it at a temperature of 700-1200°C to become a graphite worm whose volume is more than 200 times its own volume. After expansion, the appearance of graphite is fluffy Pile of powder, worm-like under the microscope;

[0025] S2. Using alkali-resistant glass fiber as the skeleton, adding graphite worms and acrylic pressure-sensitive adhesive emulsion, wherein the weight ratio of alkali-resistant glass fiber, graphite worms, and adhesive is 15:75:10. Shaped under 5 tons of pressure, made into a cloth with a width of 450-550mm;

[0026] S3, the cloth made in step S2 is divided into strips, and twisted into thin graphite threads;

[0027] S4. Twisting a plurality of thin graphite wires int...

Embodiment 2

[0031] A kind of manufacture technology that is conducive to the flexible graphite grounding body of electric conduction, comprises the following steps:

[0032] S1. Choose graphite with a carbon content ≥ 99%. After washing with water, washing with concentrated sulfuric acid, and drying, expand it at a temperature of 700-1200°C to become a graphite worm whose volume is more than 200 times its own volume. After expansion, the appearance of graphite is fluffy Pile of powder, worm-like under the microscope;

[0033] S2. Use nickel-plated stainless steel wire as the skeleton, add graphite worms and acrylic pressure-sensitive adhesive emulsion, wherein the weight ratio of nickel-plated stainless steel wire, graphite worms, and adhesive is 15:75:10. Shaped under 5 tons of pressure, made into a cloth with a width of 450-550mm;

[0034] S3, the cloth made in step S2 is divided into strips, and twisted into thin graphite threads;

[0035] S4. Twisting a plurality of thin graphite wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com