Fabricated laminated slab few-support erection construction method

A construction method and technology of laminated slabs, applied to pillars, floors, building components, etc., can solve the impact of construction period, cost and safe and civilized construction, the inability to carry out secondary structure interspersed construction in time, the spacing of vertical poles and the step distance of horizontal poles Minor problems, to achieve the effect of promoting safe and civilized construction, shortening the erection period of the frame, and reducing material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The described embodiments are only illustrations and explanations of the present invention, and do not constitute the only limitation of the present invention.

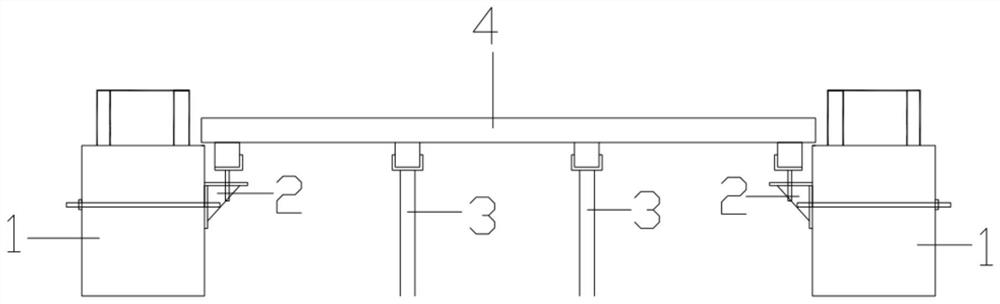

[0011] The construction method of the matching laminated slab with less support of the present invention is as follows: First, fix and position the frame laminated beam 1 by hoisting as required, and reserve a pair of steel corbels 2 for installing the laminated slab bottom support on the laminated beam Pull the bolt holes, set up a single row or double row of independent support frames 3 according to the size of the prefabricated laminated slab 4, adjust the support steel corbel 2 and the independent support frame 3 at the bottom of the slab according to the design elevation and positioning, and then the prefabricated laminated slab 4 can be carried out Hoisting construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com