Floorslab construction method used during reverse building method construction

A technology of construction method and reverse method, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of long construction period and high cost, and achieve the effect of simple operation, saving construction period and cost, and good promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

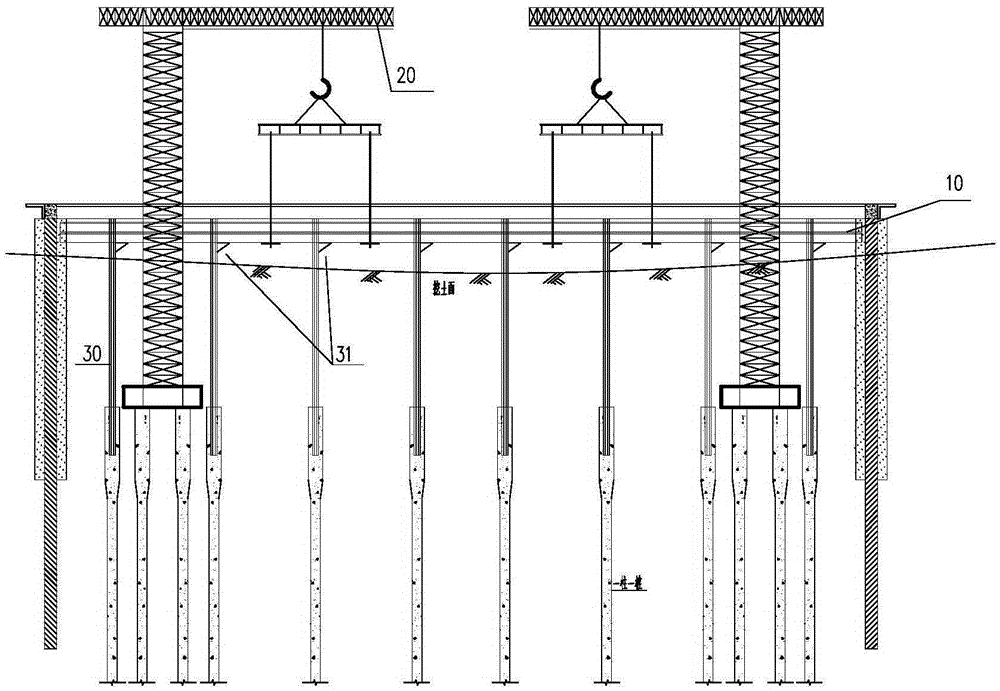

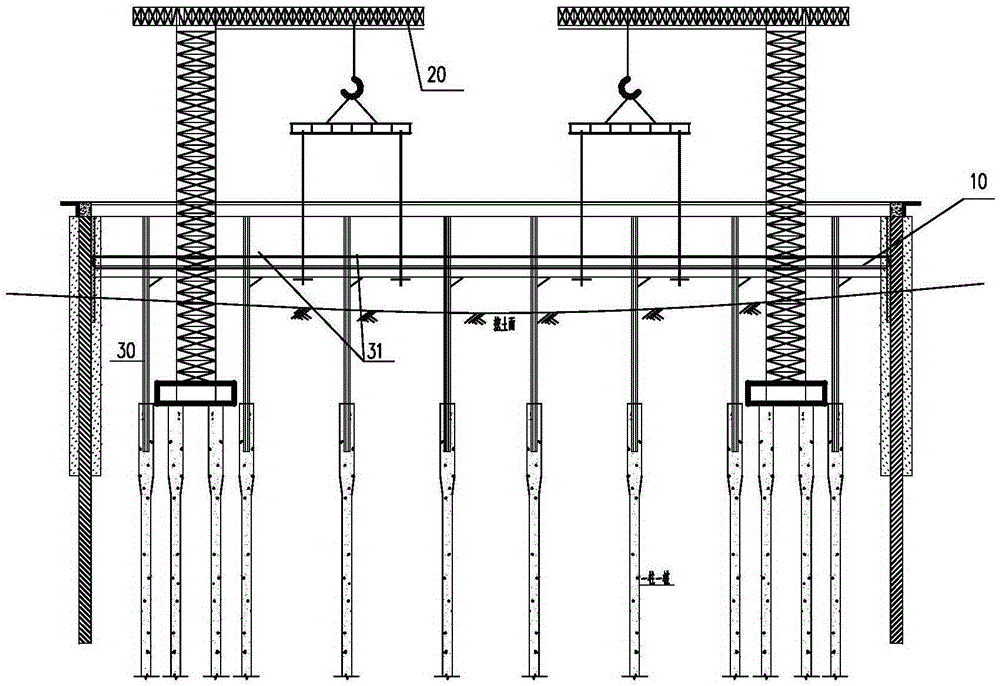

[0028] In this embodiment, the construction method of the floor slab in the reverse method construction of the present invention is described in detail by taking the construction of the third underground floor (ie when N=4) by the reverse method as an example.

[0029] Please refer to Figure 1 to Figure 5 , a floor construction method in reverse construction, the floor includes the beam-slab unit on the first floor (i.e. the roof of the basement) to the beam-slab unit on the Nth floor (i.e. the floor of the basement) from top to bottom, wherein, N is greater than or equal to 3 integer. Considering the integrity of the basement, only the beam-slab units on the first floor to the N-1th floor are prefabricated, and the beam-slab units on the Nth floor are constructed with cast-in-place concrete. This construction method comprises the following steps:

[0030] S001: Prefabricate the beam-slab units of each floor before excavation of the foundation pit for backup: starting from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com